- Joined

- Aug 18, 2011

- Messages

- 1,459

- Reaction score

- 57

Hello The Rocketry Forum,

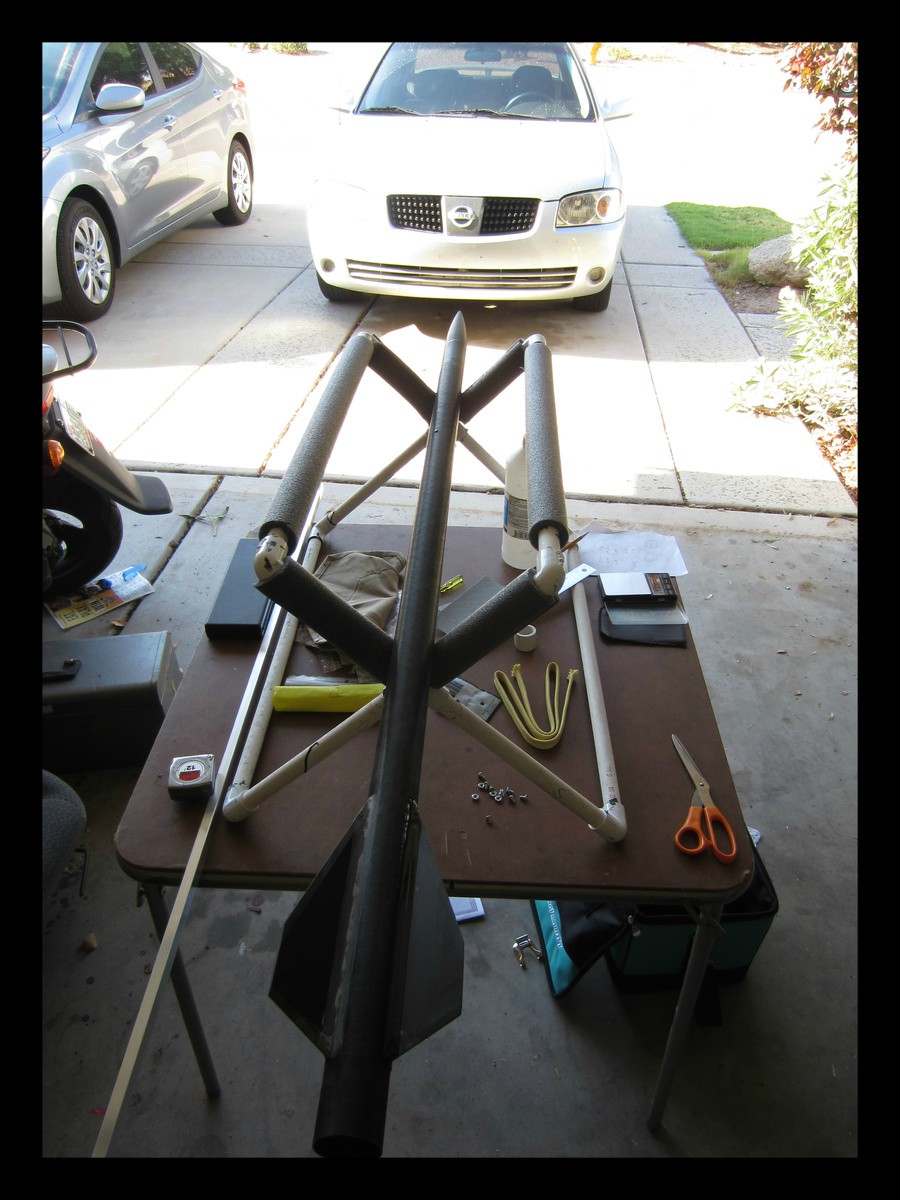

As stated in the title, this is a build thread for the famous Black hawk. I will be using this rocket for my level one certification, which is a huge goal and a big jump from any previous rocket I have built.

The goal: I was debating for a long time to either use my existing PML Spitfire, or build something new and push my abilities in rocketry. After reading numerous threads I decided its best to jump in the Level one pool, with both feet. This will be my first dual deploy rocket, the first with an altimeter controlled deployment. Also my first minimum diameter rocket, so I figured this would be perfect. This might also be my first rocket that need tracking, I am still debating on that aspect.

The issue: The launch site only has a 4,000 foot waiver with a call in window to 4,500 feet. So for this build I am not trying to push out every inch of performance. I will be using the smallest impulse motor to qualify for a Level one certification, but to keep it under that flight window. Also I will be using plastic rivets to hold the collar for the shock cord, and the coupler, and don't forget the launch lugs. With all of these it should keep it under that 4,500 feet range.

I forgot to mention, I will be using a CTI motor for this beast. I was looking into the H123, but I am still researching what motor I would like to use.

I also included the RASAERO/Open Rocket files for the rocket, these are exact measurements to my kit via a digital caliper.

View attachment bh38.alx1

View attachment Blackhawk 38, Stock.rkt.ork

As stated in the title, this is a build thread for the famous Black hawk. I will be using this rocket for my level one certification, which is a huge goal and a big jump from any previous rocket I have built.

The goal: I was debating for a long time to either use my existing PML Spitfire, or build something new and push my abilities in rocketry. After reading numerous threads I decided its best to jump in the Level one pool, with both feet. This will be my first dual deploy rocket, the first with an altimeter controlled deployment. Also my first minimum diameter rocket, so I figured this would be perfect. This might also be my first rocket that need tracking, I am still debating on that aspect.

The issue: The launch site only has a 4,000 foot waiver with a call in window to 4,500 feet. So for this build I am not trying to push out every inch of performance. I will be using the smallest impulse motor to qualify for a Level one certification, but to keep it under that flight window. Also I will be using plastic rivets to hold the collar for the shock cord, and the coupler, and don't forget the launch lugs. With all of these it should keep it under that 4,500 feet range.

I forgot to mention, I will be using a CTI motor for this beast. I was looking into the H123, but I am still researching what motor I would like to use.

I also included the RASAERO/Open Rocket files for the rocket, these are exact measurements to my kit via a digital caliper.

View attachment bh38.alx1

View attachment Blackhawk 38, Stock.rkt.ork

Last edited: