peter_stanley

Well-Known Member

- Joined

- Apr 11, 2009

- Messages

- 222

- Reaction score

- 1

I designed a micro scale Nike Hercules, and started working on the sustainer this week. I ordered most of the parts from Fliskits.

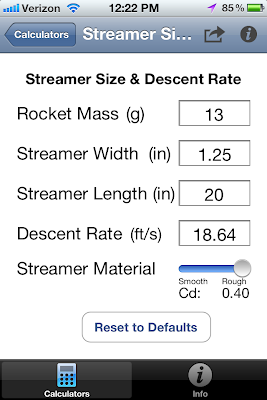

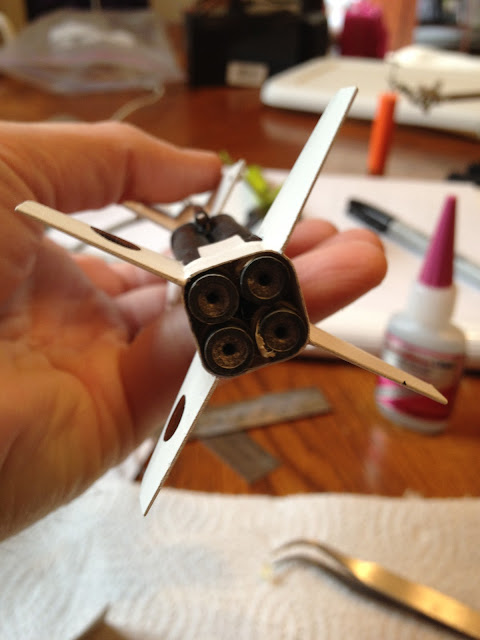

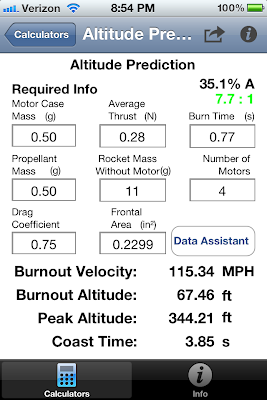

I plan to fly the full stack as a single stage, four motor cluster. I did install a motor mount in the sustainer in case I figure a good way to stage it. I might fly the sustainer by itself if it's not too heavy.

Here are some pics of the build so far. I'm also attaching the Rocksim file, but the most current one can always be found on my site.

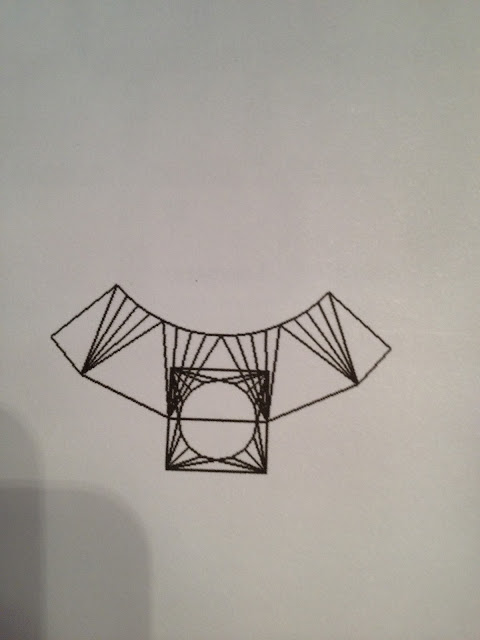

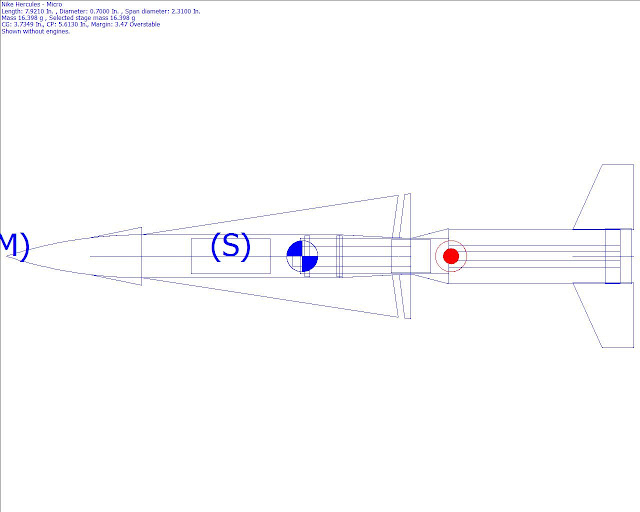

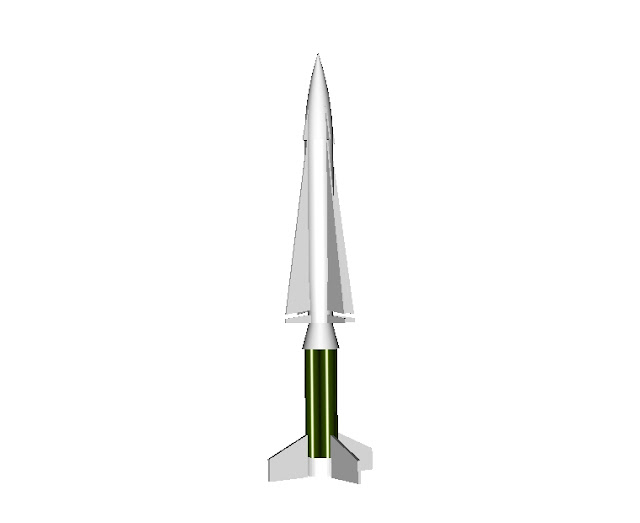

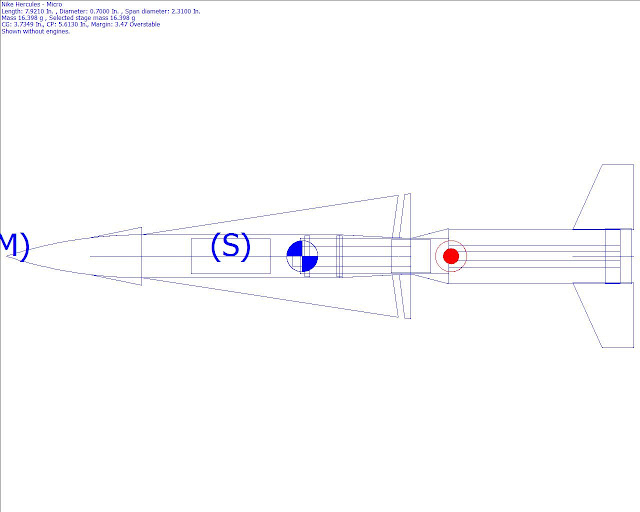

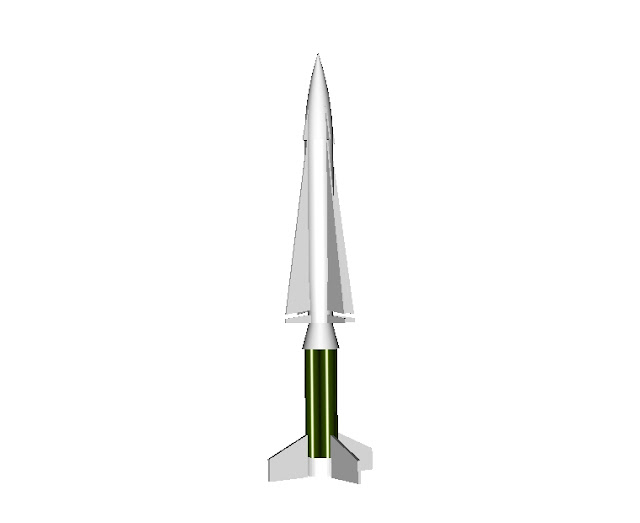

Rocksim images:

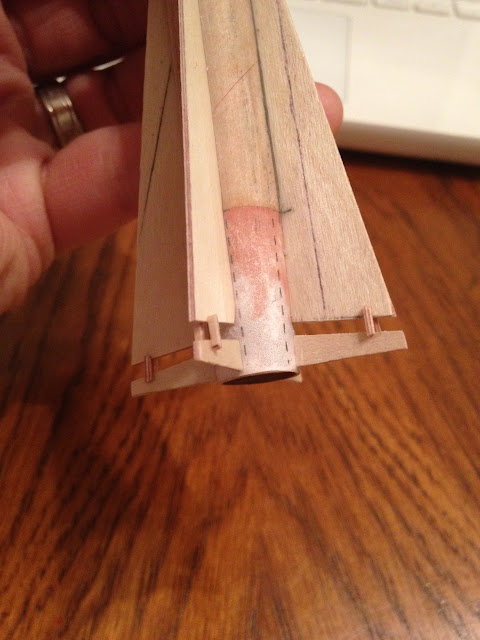

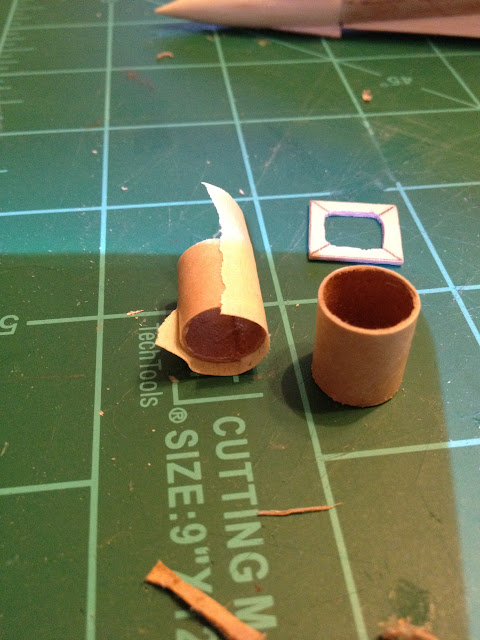

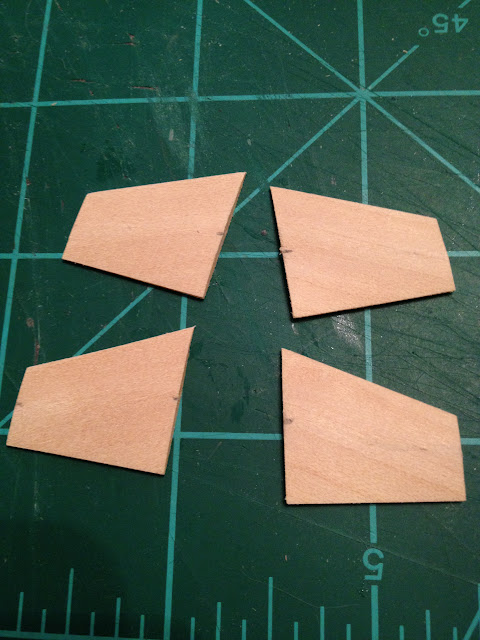

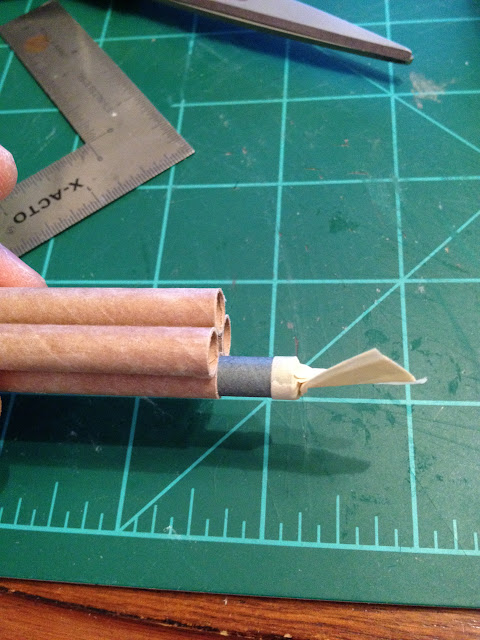

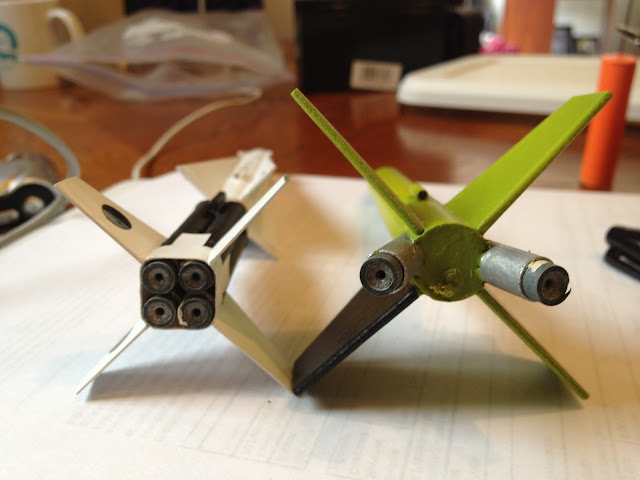

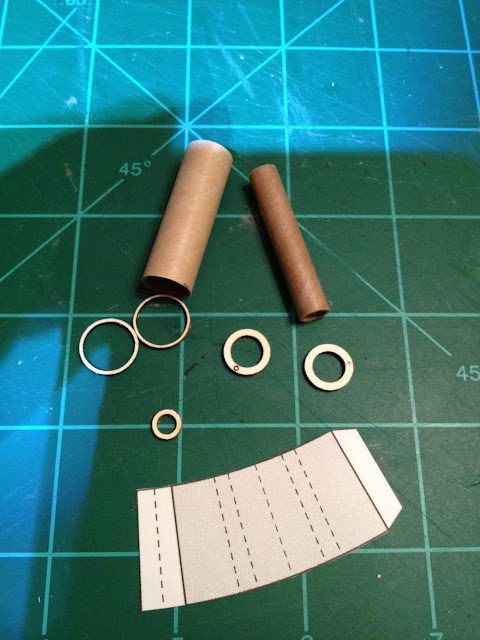

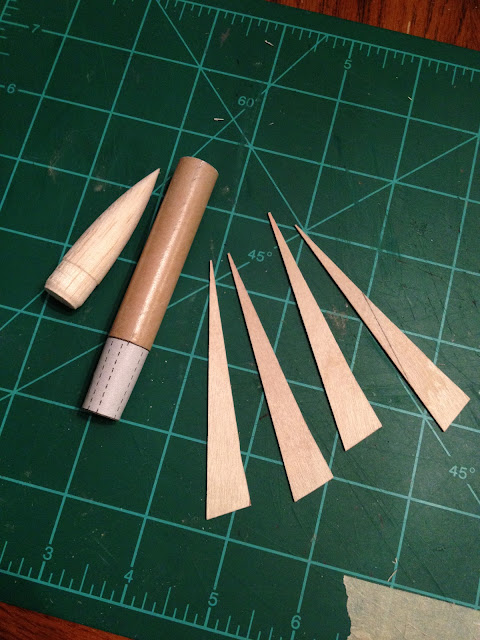

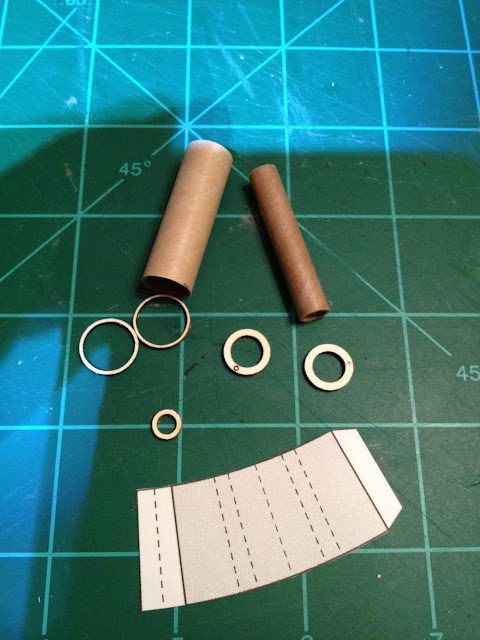

The motor mount/tail cone assembly parts:

I steamed the tail cone wrapper to help form it.

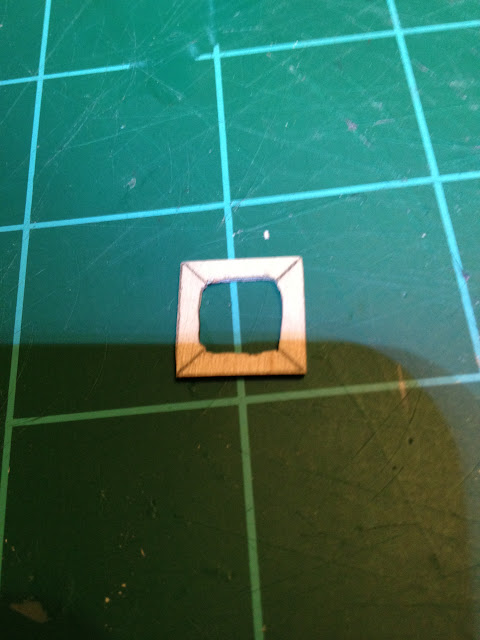

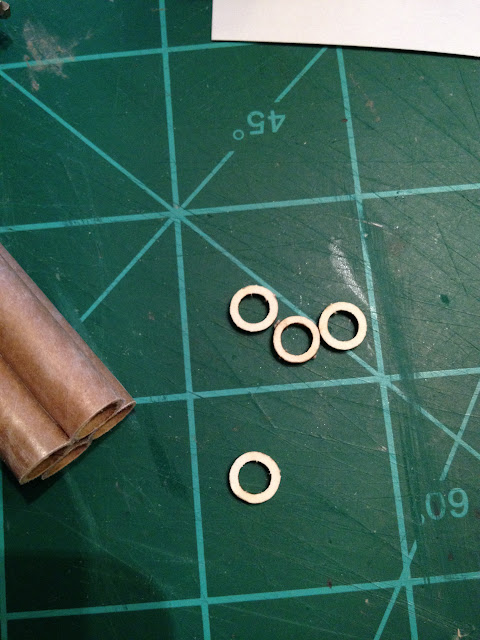

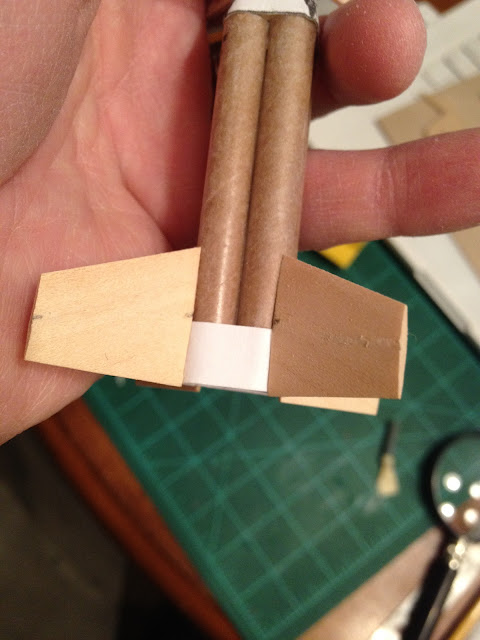

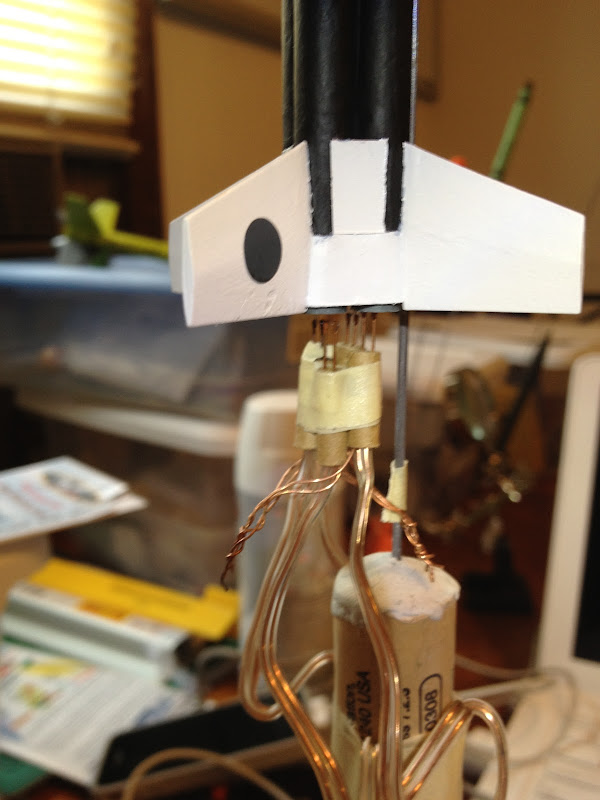

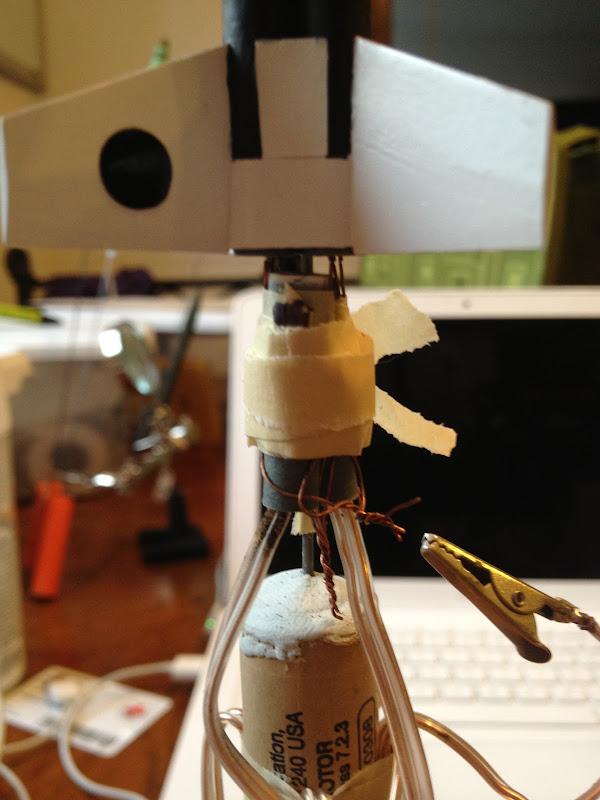

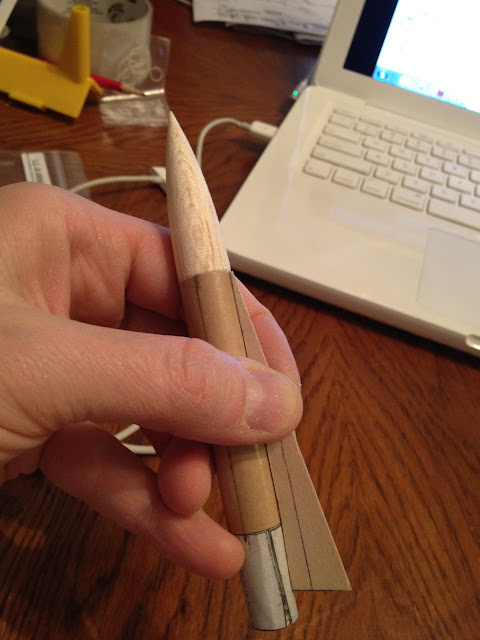

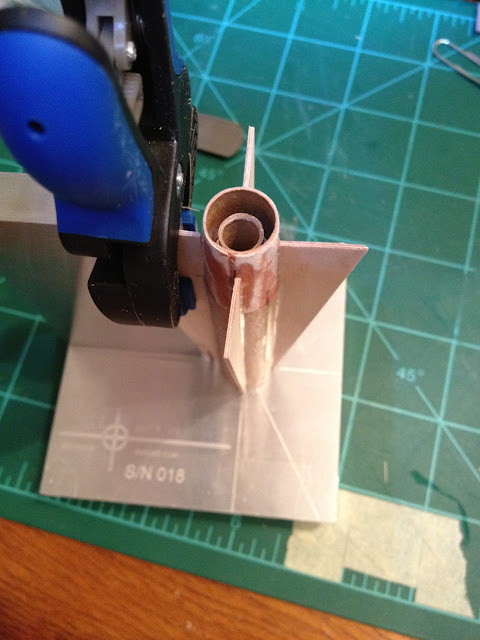

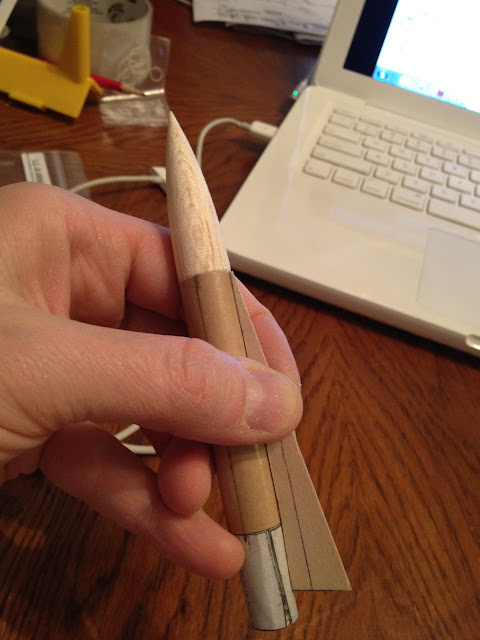

Motor mount: (I'm getting used to these tiny parts)

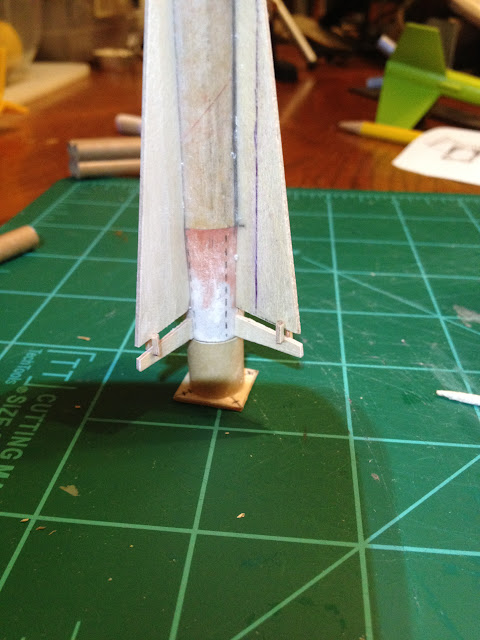

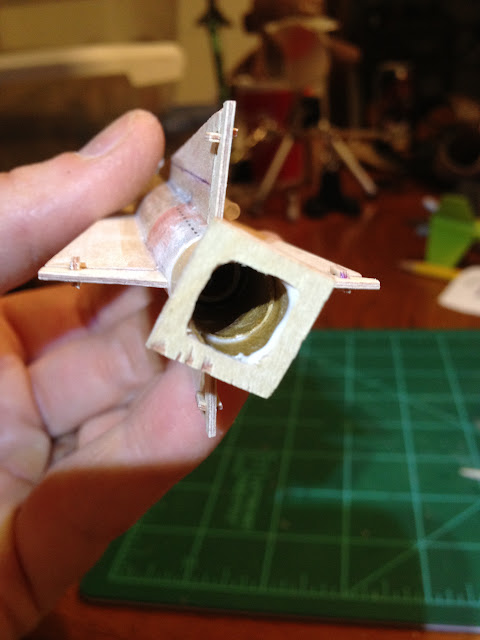

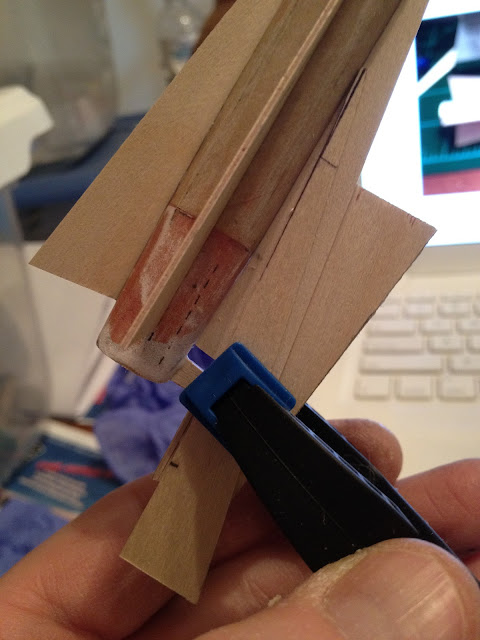

Some pics of the tail cone assembly:

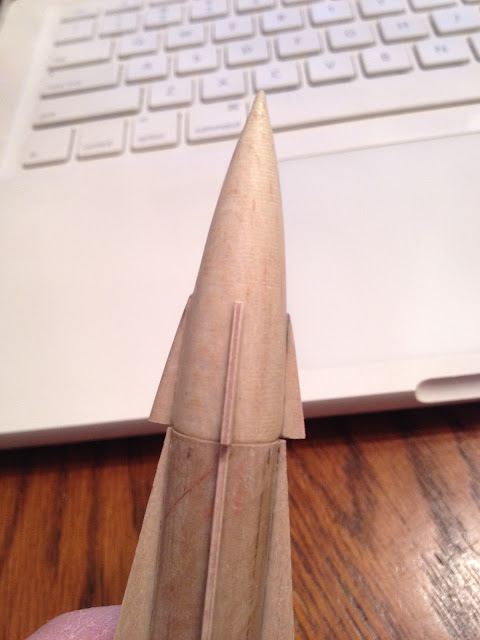

The new Fliskits NCB-5K nose cone is pretty close to the shape and length I needed.

Roughly holding it together here:

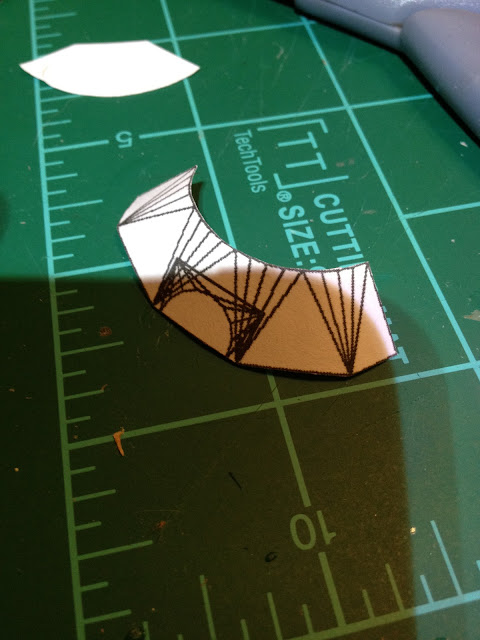

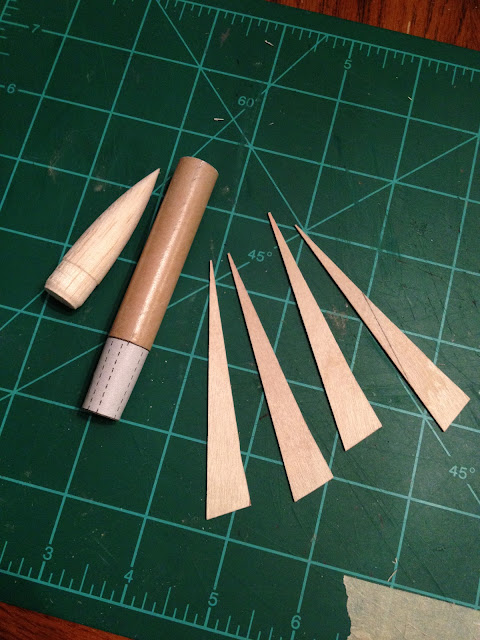

Fins:

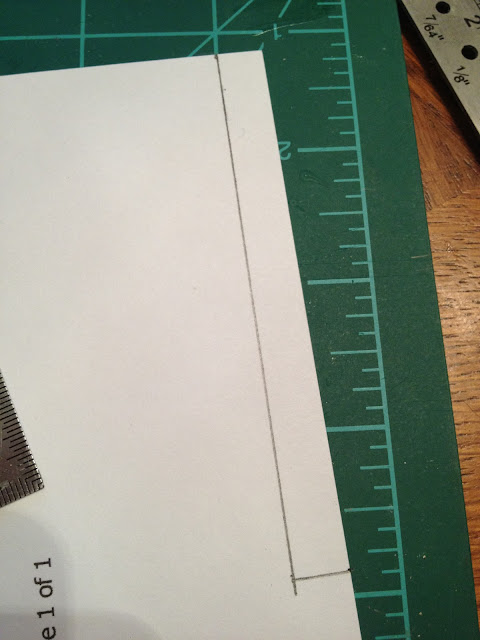

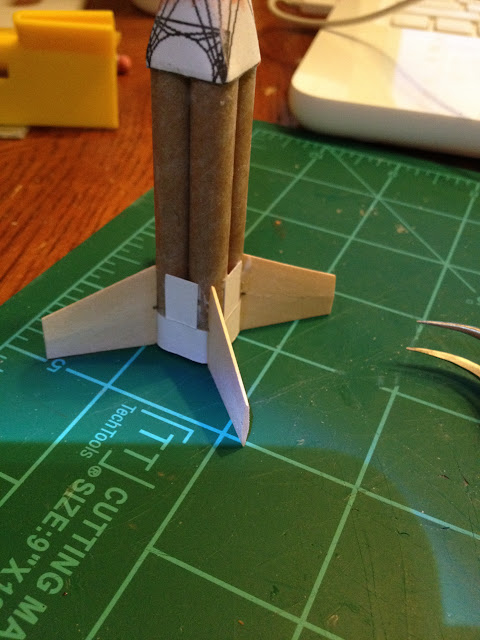

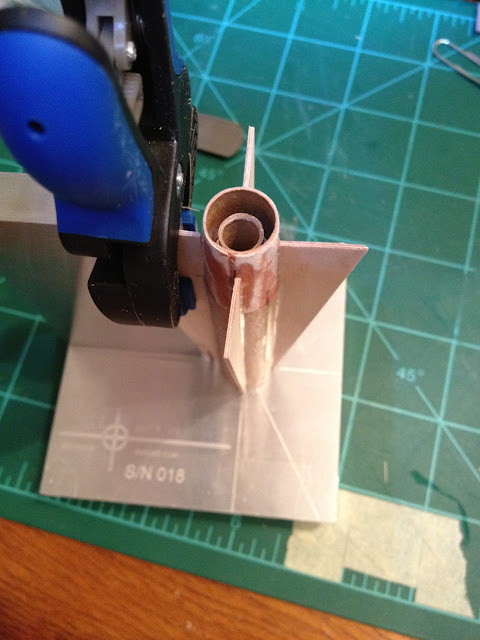

I'm finally making use of my Ulf's fin jig:

Starting to look really cool:

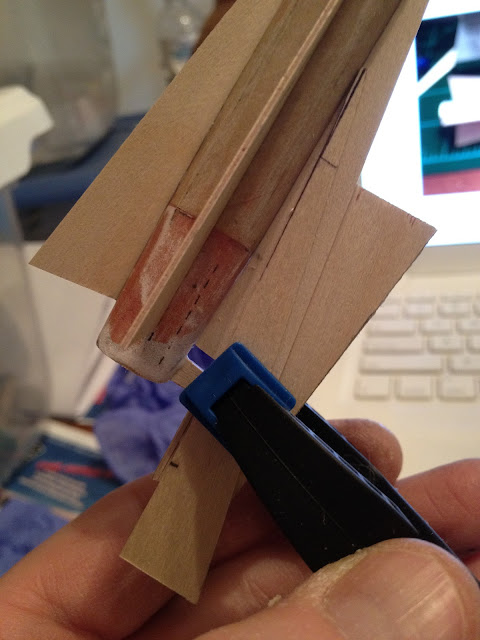

Bottom fins:

That's pretty much where I'm at with it now.

View attachment nh_mmx2.rkt

I plan to fly the full stack as a single stage, four motor cluster. I did install a motor mount in the sustainer in case I figure a good way to stage it. I might fly the sustainer by itself if it's not too heavy.

Here are some pics of the build so far. I'm also attaching the Rocksim file, but the most current one can always be found on my site.

Rocksim images:

The motor mount/tail cone assembly parts:

I steamed the tail cone wrapper to help form it.

Motor mount: (I'm getting used to these tiny parts)

Some pics of the tail cone assembly:

The new Fliskits NCB-5K nose cone is pretty close to the shape and length I needed.

Roughly holding it together here:

Fins:

I'm finally making use of my Ulf's fin jig:

Starting to look really cool:

Bottom fins:

That's pretty much where I'm at with it now.

View attachment nh_mmx2.rkt