dixontj93060

Well-Known Member

- Joined

- Feb 19, 2009

- Messages

- 13,083

- Reaction score

- 45

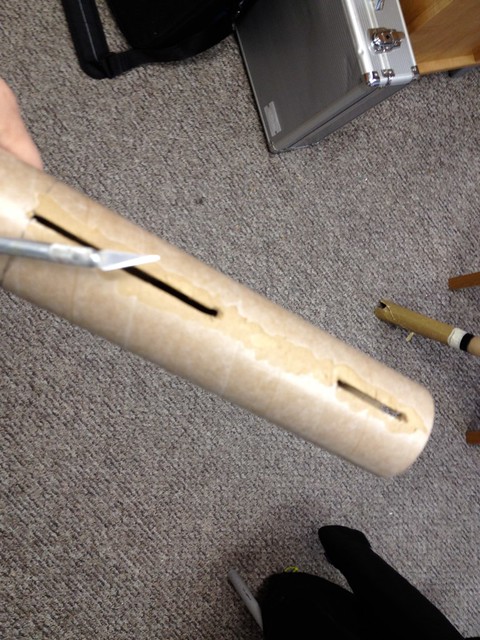

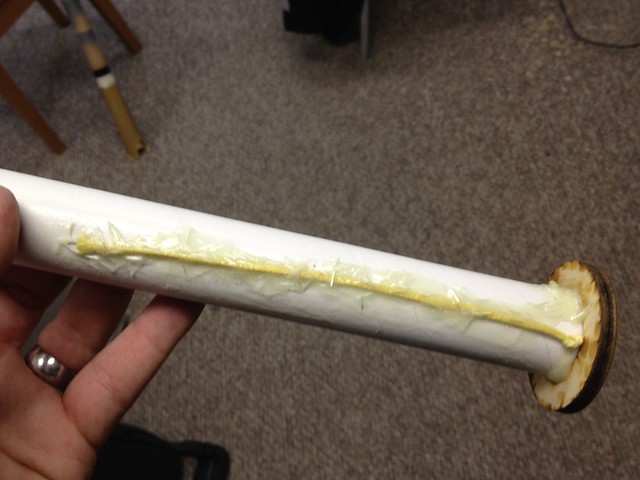

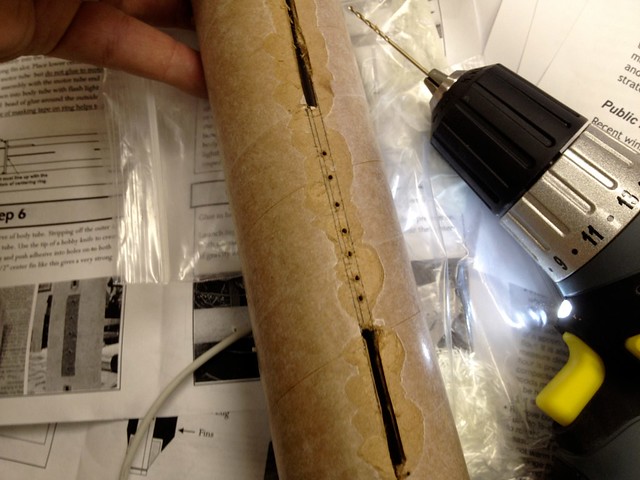

Well on Thursday afternoon I received an order from 3D Rocketry. I have 50+ high power rockets in my build queue so this one was just going to go up in the attic and wait it's turn. But there it sat on my guest chair in front of my office desk, and dang that Bill Carpenter (Slickwilly), he put a picture the rocket on the outside of the box! As I looked at that picture and the sexy lines of the rocket, it just started calling out to me like a siren, pulling me closer, into the rocks... (I thought... Can't be that bad... The other four rockets I'm building can wait... I have some 5 minute epoxy here in the office... Finished all my client work and deadlines... Oh well... [ripping the box open!!])

Last edited: