Here is my cheap (may I say red neck) launch tower... Taking advantage of both the soft ground in the Midwest corn and bean fields and my father-in-laws welding hobby here are the components:

It's fairly portable--fits, at least mostly, in a standard "rocket shipping box."

First pick your scrap iron base with proper hole spacing (or multiple holes laid out with BSD/Binder fin guide).

Take rebar ($9) with welded washers ($0.35) at 18" and sharpened ends and pound them in the ground through the desired base holes.

Then slide 1" PVC down and over each rebar section.

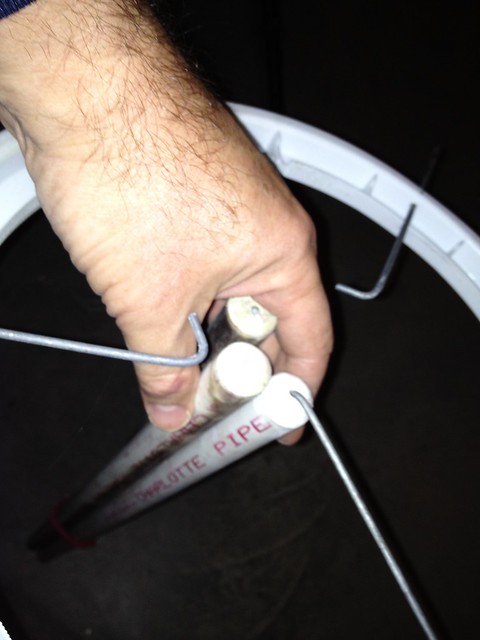

But note, these aren't just four foot sections of PVC ($4), they have epoxy putty plugs ($1) in one end and have 1/8" holes in each center. These holes conveniently hold an "L-shaped" spacer at the top of the PVC sections. And you will note that the spacer (a bicycle spoke or equivalent, $0 scrap) emanates equidistant from a plastic ring ($1 bucket top with center cut out) in which they fit tightly in "press fit holes".

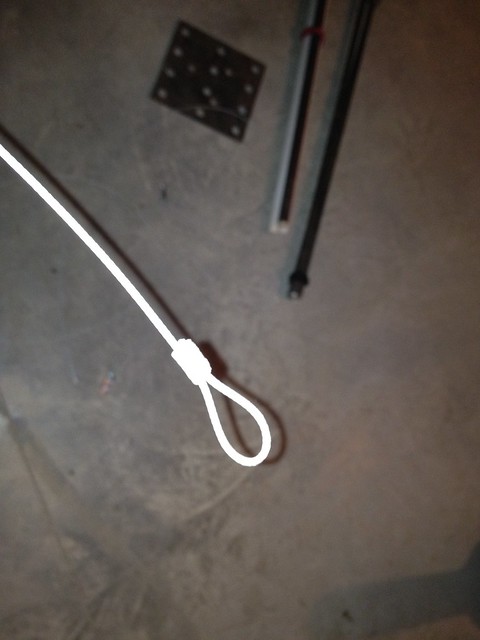

Conveniently this modified bucket top also has press fit holes that accept cotter pins ($0.50) and attach to a crimped loop of 1/8" cable (18' in total, $7)

Which, in turn, get staked into the ground on the other end to stabilize the top of the rebar/PVC sections.

Follow the procedure and you are ready to do some red neck high altitude rocket launchin'!!!