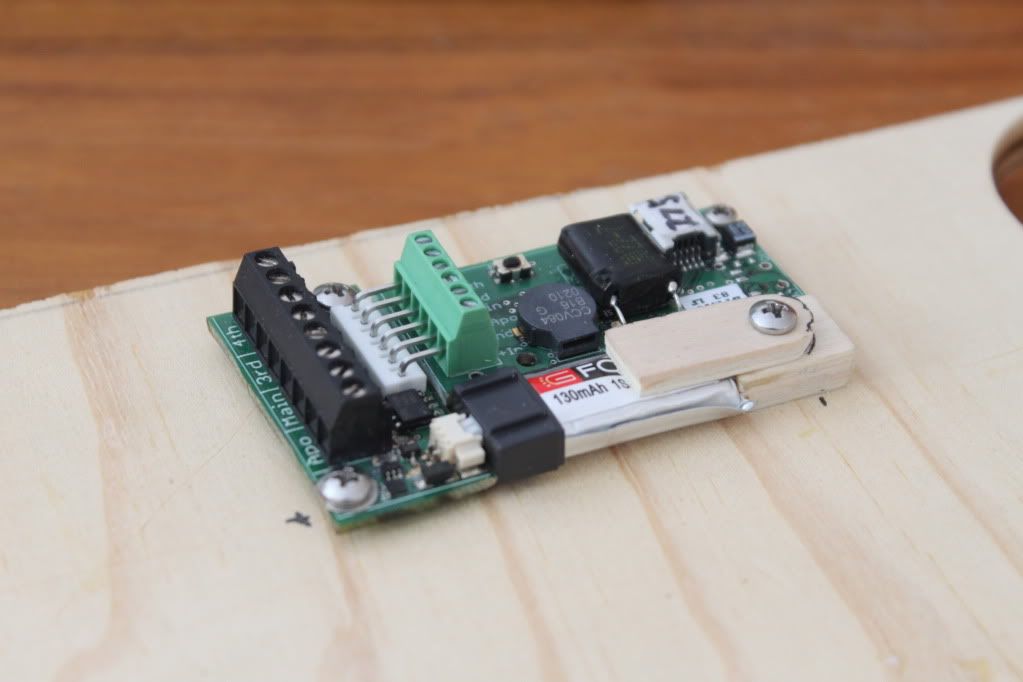

Adrian - Do you have a source for a female connector with leads to the li-po batteries you use so I could utilize the same batteries in other altimeters? Huge weight saver, and rechargeable to boot.

https://www.all-battery.com/molexconnector80075.aspx