GregGleason

Well-Known Member

- Joined

- Nov 13, 2009

- Messages

- 4,674

- Reaction score

- 45

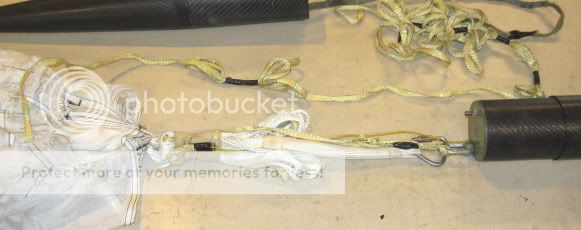

Out of curiosity, has anyone tried a staged chute deployment using a reefing line/cutter apparatus? It's probably been done, but I wonder how much trouble it is to implement.

Greg

Greg