Winston

Lorenzo von Matterhorn

- Joined

- Jan 31, 2009

- Messages

- 9,560

- Reaction score

- 1,748

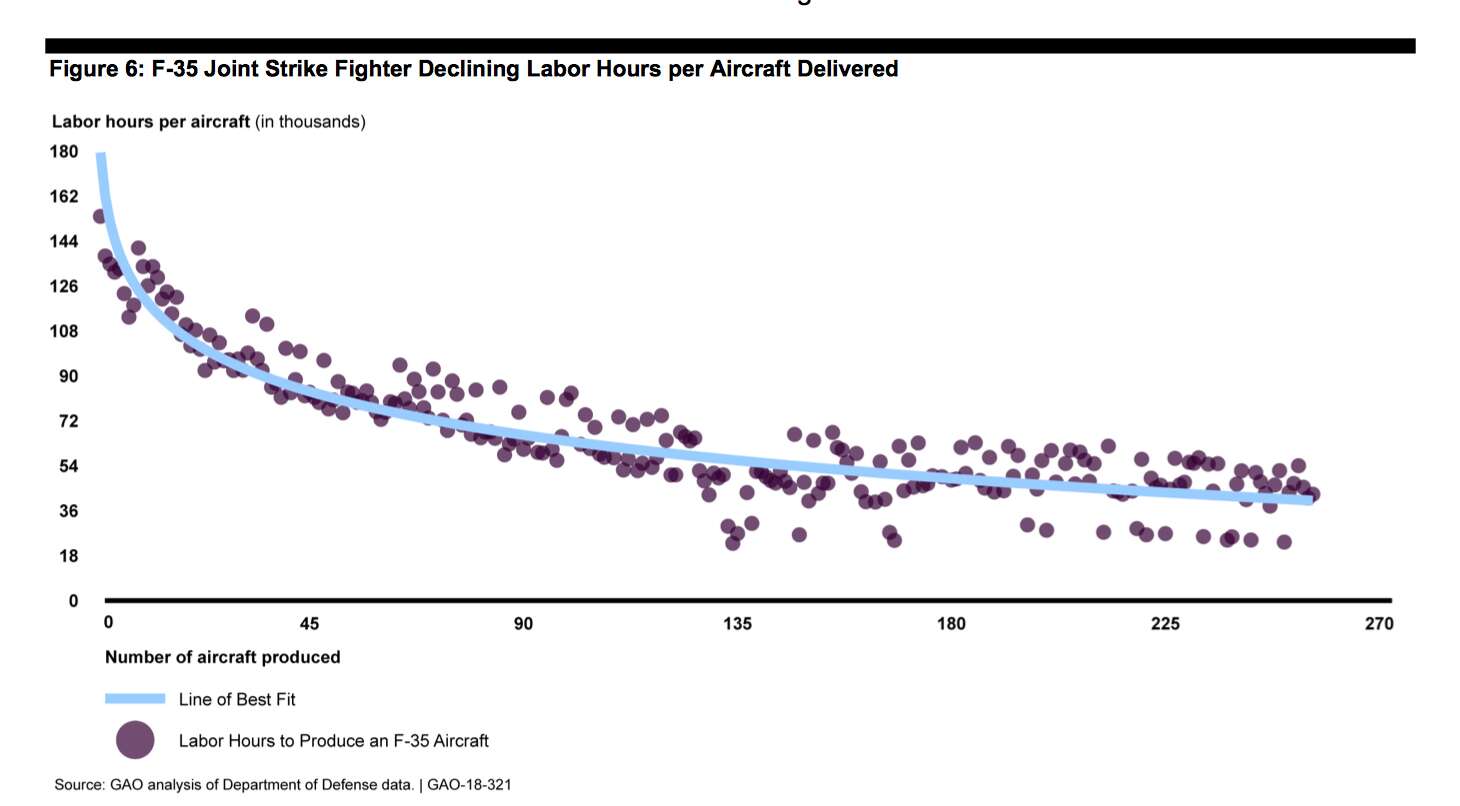

It Takes 41,500 Hours Of Labor To Build A Single F-35A According To New Report

The time it takes for workers to construct an F-35 is decreasing according to a new report, but other issues with the jet haven't been resolved

6 Jun 2018

https://www.thedrive.com/the-war-zone/21367/it-takes-47000-hours-of-labor-to-build-a-single-f-35a

Excerpts:

As far as the question of how the F-35's labor hours for production compares to other aircraft, we are having a tough time answering it definitively at this time, at least with fresh data. But according to an archived POGO report, an F-16A took 29,000 man hours to produce in 1984, and the more complex and relatively new F-16C took 45,000 man hours to build in 1989. That same source noted that just the F-22's center fuselage section took 60,000 man hours to assemble when the program was in its pre-production state in the late 1990s. This was mainly due to the 60,000 fasteners that were used on the section, each of which was installed by hand taking roughly 30 minutes to an hour.

So with just these metrics in hand, the F-35 program doesn't seem to be gobbling up labor at an astronomical rate, especially considering its low-observable design, which are historically very expensive to produce. The fact of the matter is that all aircraft take a lot of time to build. Even during World War II, when the fate of Britain hung in the balance, it took a whopping 13,000 man hours to build a single Spitfire Mk V. In contrast, it took the Germans 4,000 hours to build a Me109G.

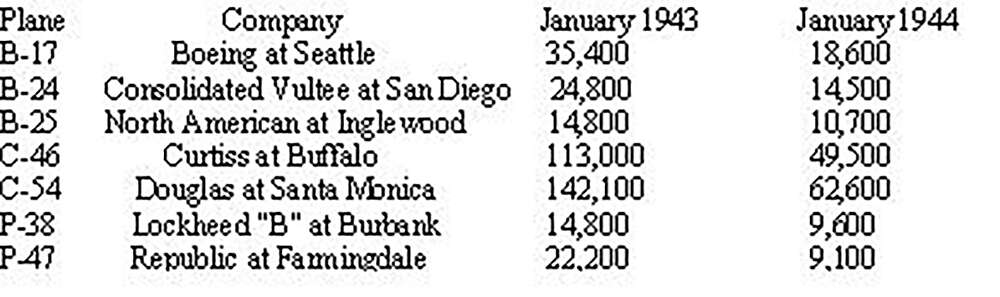

We found the chart below in the forums at WW2Aircraft.net and we can't confirm its accuracy, but it seems to be a good comparative snapshot of the time it took to build other WWII aircraft. You will notice the massive delta in efficiency just over a single war year for all the types stated:

The time it takes for workers to construct an F-35 is decreasing according to a new report, but other issues with the jet haven't been resolved

6 Jun 2018

https://www.thedrive.com/the-war-zone/21367/it-takes-47000-hours-of-labor-to-build-a-single-f-35a

Excerpts:

As far as the question of how the F-35's labor hours for production compares to other aircraft, we are having a tough time answering it definitively at this time, at least with fresh data. But according to an archived POGO report, an F-16A took 29,000 man hours to produce in 1984, and the more complex and relatively new F-16C took 45,000 man hours to build in 1989. That same source noted that just the F-22's center fuselage section took 60,000 man hours to assemble when the program was in its pre-production state in the late 1990s. This was mainly due to the 60,000 fasteners that were used on the section, each of which was installed by hand taking roughly 30 minutes to an hour.

So with just these metrics in hand, the F-35 program doesn't seem to be gobbling up labor at an astronomical rate, especially considering its low-observable design, which are historically very expensive to produce. The fact of the matter is that all aircraft take a lot of time to build. Even during World War II, when the fate of Britain hung in the balance, it took a whopping 13,000 man hours to build a single Spitfire Mk V. In contrast, it took the Germans 4,000 hours to build a Me109G.

We found the chart below in the forums at WW2Aircraft.net and we can't confirm its accuracy, but it seems to be a good comparative snapshot of the time it took to build other WWII aircraft. You will notice the massive delta in efficiency just over a single war year for all the types stated: