Rockethound

Infinity is in our minds

If you’re opening up to the idea of flying Gs single deploy (which I think will be much simpler and less stress)...

Build the dinghy first.

The Optima is an Estes rocket from the mid 90's.

SARG has the bigger rail pad, and at least one longer rail for the smaller pads. They don't usually use them at Gibson Ranch, though.

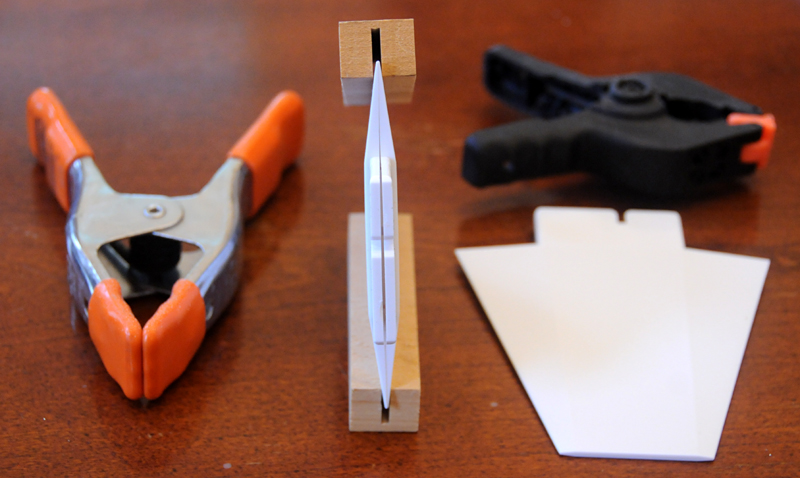

One benefit of a JLCR is t so much avoiding using BP, but being able to do DD out of a single break in the airframe.

A cert rocket just needs to go up on an H and land intact.

I wanted to mention that I think JLCR is one of the greatest innovations for model rocketry in recent times.

The Nike Smoke caught my eye and may be in the long-term lineup.

A funny thing happened this Saturday. Curious, as a funny thing happened last Saturday and turned out great. Today was even more random.

I suppose only a few of you know the next SARG launch is 24 March, while most of you know today is 17 March. I didn't. I drove up to an empty Gibson Ranch where the gal at the gate told me there were no rockets today. I realized what I did and decided to go to R/C Country Hobbies. We're lucky to have such a good LHS nearby! I've known the owners 25 years or so, and for some reason Terri was near the front door. She said Hi to me and asked what I was in for today. "Do you have any big rockets?" She knows me and had a good idea of what I'd want, and walked me to the rocket section. "Here's our largest diameter" - pointing at the Estes Nike Smoke.

I checked at the counter. They had four G40-7 motors. A quick trip home, found the Rocksim file, and a G40-7 looks great. Apogee is 1050', off the rod at 52.4 FPS, optimum delay 5.78 seconds... the rocket is light for its Cd so it doesn't speed up much over the top; the 7 second delay results in 35 FPS at deployment. And... tada... an H55W-6 hits 2100', off the rod at 54.3 FPS, deploys (1 sec early) at 35 FPS.

I bought the Estes Nike Smoke and two G40-7's. I can fly the L1 cert flight with this rocket.

I can have it built by next Saturday and fly at SARG rather than just watching. It doesn't need a rail.

I'll be getting a JLCR as a matter of course now. No problem finding it from 2100' with a CR.

I got a missile.

What an odd way for this to turn out! It's also great in its own way. I can research the more expensive rockets, decide what I want, build the next one well, and don't need to spend the whole wallet at one time. Go figure.