Hi David,

You presented a lot of new information for me to process. Let's do thrust curves first. I had looked at them, but I hadn't carefully compared the curve with the various performance characteristics with a given rocket. I did so this morning with the BH38 because its OR file is set up the best of what I have.

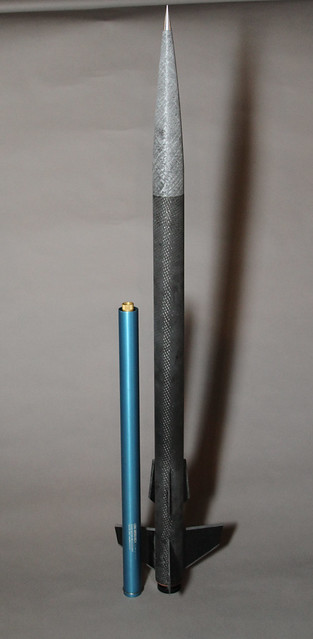

The BH is 1174g no motor in the OR file. Your first two motors simmed nicely: G76 off rail at 61.6 FPS, apogee 1033. Compare this to the G64 I had in my list; almost the same apogee but off the rail was only 48.3. The G80 you listed wasn't quite as good as the G76 (I'm learning so much); apogee went up 50 feet but velocity off the rail down to 52 FPS.

Your third thrust curve was for the AT G69. While its apogee is 1262 (+200), it comes off the rail at just 44.4 FPS. Would it be fair to say that this motor would be reasonable for a large-finned rocket but inappropriate for the small-finned BH? It seems there must be a place for all these motors, and it does give more altitude.

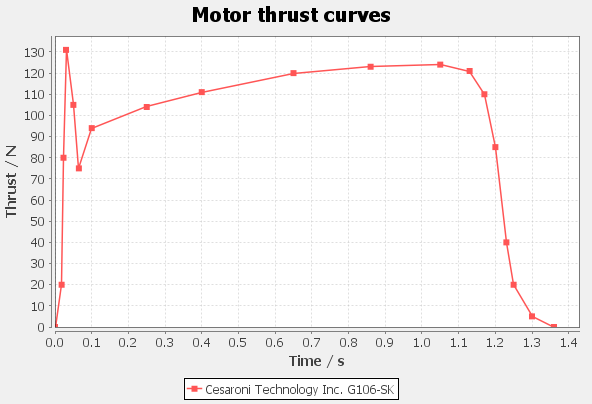

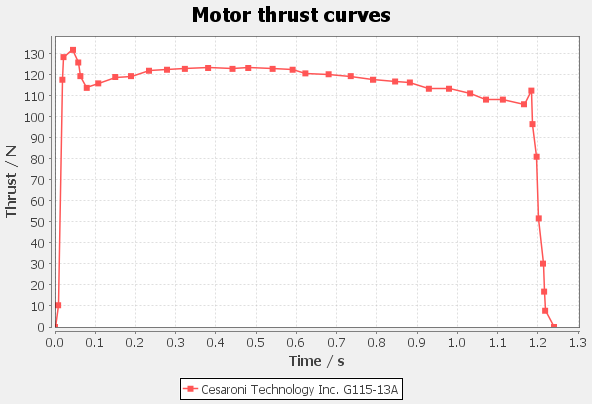

Now, on to the CTI motors. You have a G46 there, kind of a shame because that's their lowest power 38mm G motor, but it has an obvious thrust spike at ignition. That spike seems to be fairly common with CTI, at least for those I've looked at. This is a CTI G106:

The G106 has a fairly pronounced spike. Apogee 1357', off the rail at 51.5 FPS.

The G115 has a less-pronounced spike, but still leaves the rail at 55.7 FPS and reaches 1407'. Both seem like worthwhile motors; the G115 being better for a BH.

Is there any reason to prefer AT or CTI in general? Or is it more a matter of personal preference, mounting style / case design, or suitability for a particular rocket? Is there a reason for the early CTI thrust spike, such as vel off the rail?

- the Blackhawk is a screamer with tiny fins. At M1 no big deal. At lower speeds the small fins will correct angle of attack differently than larger fins at low speed. Not a dealbreaker, but be aware of it if its windy and your using a G with lower average thrust.

First - thank you for bringing up important design points. I still have no way of judging what is a suitable flight plan for the small-finned BH. CJ had about a dozen motors already in the OR file. I161's leave the rail in the low 50's; I211 is 66.3 and I301 is 63.2.

Would it be correct to believe the G76, G106 CTI and G115 CTI would have sufficient velocity to respond well to wind gusts, as they leave the rail at similar speeds to the more powerful motors?

I'm not suddenly focused on the BH above all others. It's more like I'm trying to comprehend the nature of your caution and what steps can be taken to avoid possible problems, using the only decent OR file on hand.

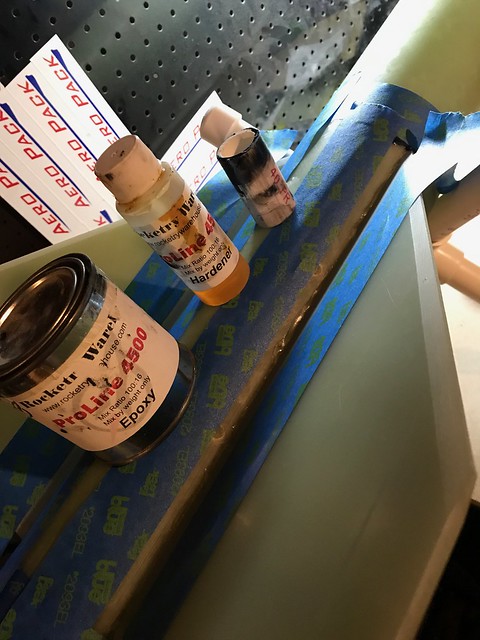

The Zodiac is a different beast, being 54mm. Do you have an OR file for yours? How long did they cut the fin can? I'm going to call MAC and learn more about phenolic. There's surprising little to be found on the net - or I've done a poor job of searching.