Wie Gehts, Steinhund,

Ja, ich werde den Thread lesen...

Ist etwas einfacher einzurichten als das DX3?

Es geht gut, danke.

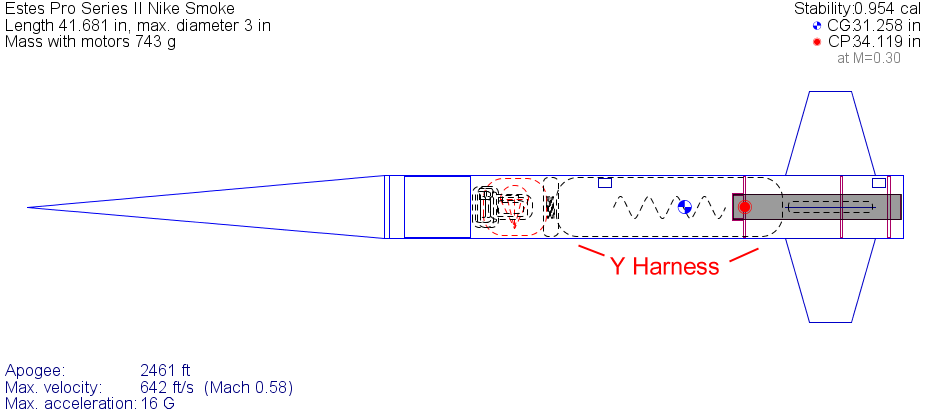

I started looking for L1 rockets at Madcow, and there is a thread by Caley about her efforts to build a DD DX3. As I learned in this thread, a lot of factors enter into the L1 choice. I liked the NASA-style drouge/main deployment and was aiming at all DD rockets, the DX3 and Tomach among them and the Blackhawk 38 very near the top.

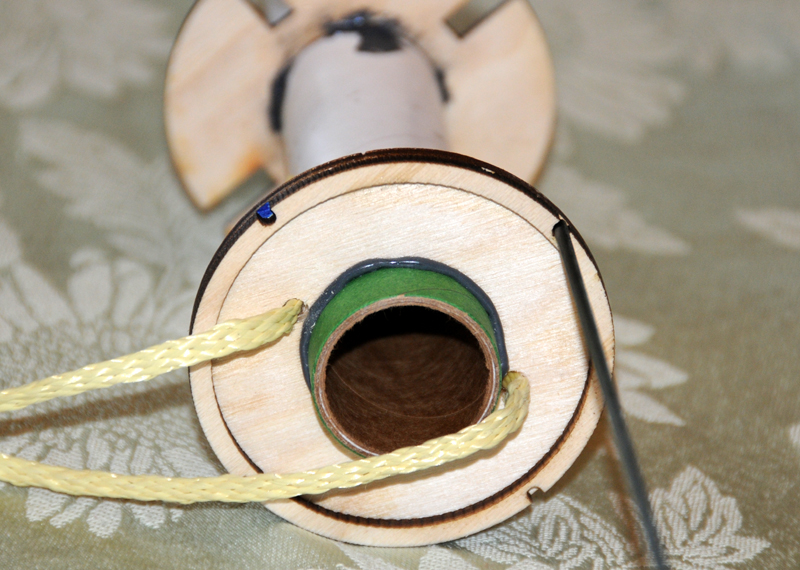

If you build a DX3 single deployment, it won't involve much more complexity than the Smoke I'm building. If it's a 38mm body tube, you'll find yourself working in cramped quarters. Because of my 25+ years building FG and CFK R/C models, I felt well-equipped for a 38mm rocket.

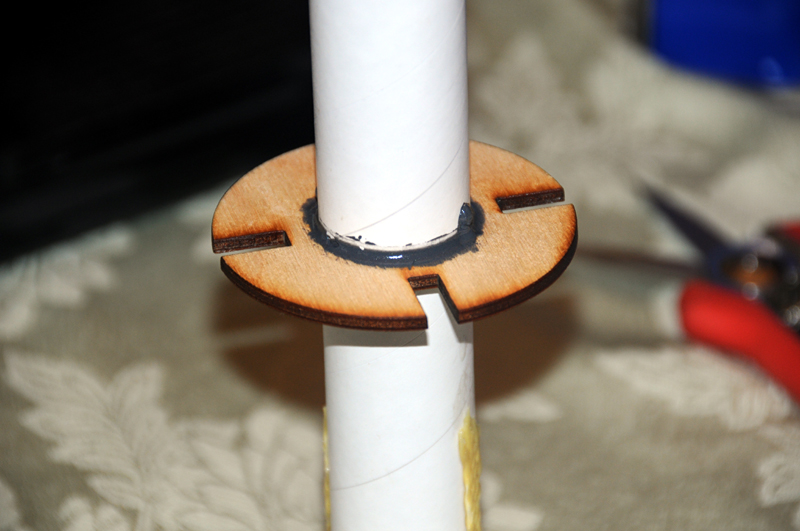

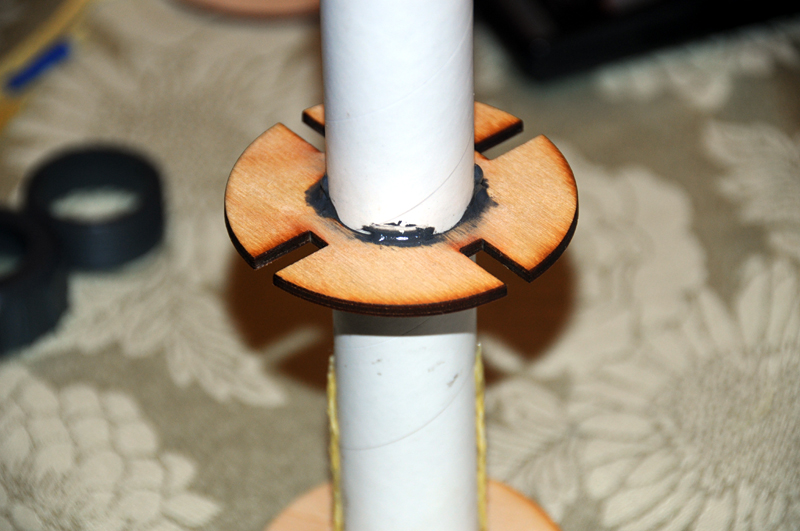

Maybe I would have built it well, but I would not have finished it in a week for sure. With the Estes Nike Smoke Pro Series 3", I will be finished in a week (save painting). There's a lot of body tube to work in, which makes tasks we didn't encounter in R/C easier to manage, and gives me skills for a 38mm rocket. The fat body tube lets me use a Jolly Logic Chute Release (JLCR), which just barely fits in a 38mm and doesn't fit in some of them. With my fat rocket, packing is no issue and the JLCR could practically fit in sideways.

Then there is the "Where did it go?" issue. By building a short, fat, lightweight rocket (with lots of base drag, hehe), I can use a rewarding H motor and see the rocket the whole flight. If you build a 38mm DX3, to quote another TRF member: "Can you see a yardstick a mile away?" Do you really want to deal with tracking? Choices seem limited: a simple Tx and a Yagi array antenna to get an azimuth but no distance, or earn your tech level Ham license and use a GPS Tx that pinpoints its location (even as it drags across a field, as David McCann learned).

Why do all this complexity? Why build so many things that all have to work together on a cert flight? Please, start on page one here and see what happened to me. Black powder is no big deal to me, electronics are no issue, and perhaps because of my German ancestry, I enjoy complexity. But I'm building an Estes rocket, and you should read the joy that came from others when I accidentally found myself buying a Smoke. They knew what I now know: KISS principle, or "Build the dinghy first."

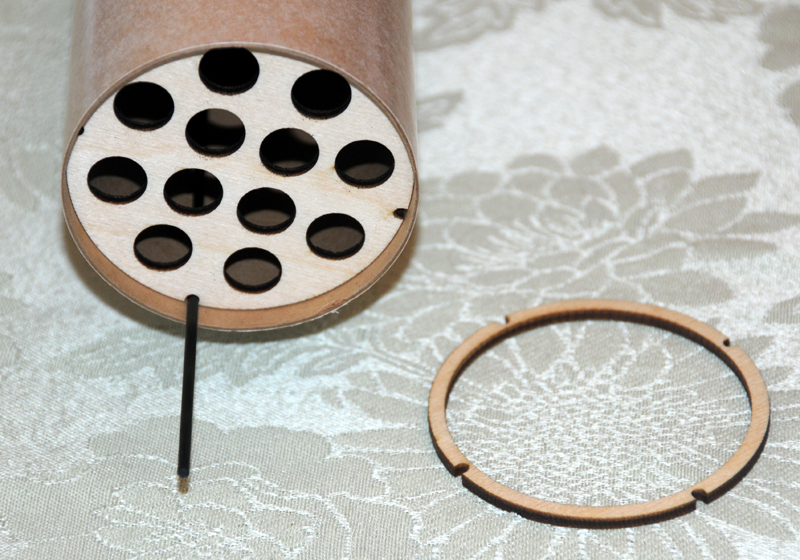

It may not sound like your style. It isn't my style. But I am very pleased with what I am doing. Today I'm going to build some carbon fiber braces into the body tube to strengthen it for the larger H motors. I have become proud of this cardboard Estes rocket - I'm building it my way, expressing myself. I hope you either have the build background for the DX3 and the electronics laying around, or you see the value of using a $50 kit, building it quickly and strong, getting your cert and moving on to the rockets that intrigue you. Surprisingly, I'll not build a Blackhawk 38 next as I assumed, but maybe a Darkstar 2.6. Heavy rockets let you watch them for a longer time.

And then there is the adrenaline rush of the H410 motor; the video is fun to see and shows why he fell in love in less than a second. But remember, he lost his rocket for that rush. For him, that trade was worthwhile. Express yourself.

Shoenen guten Tag!