CoachSteve

Well-Known Member

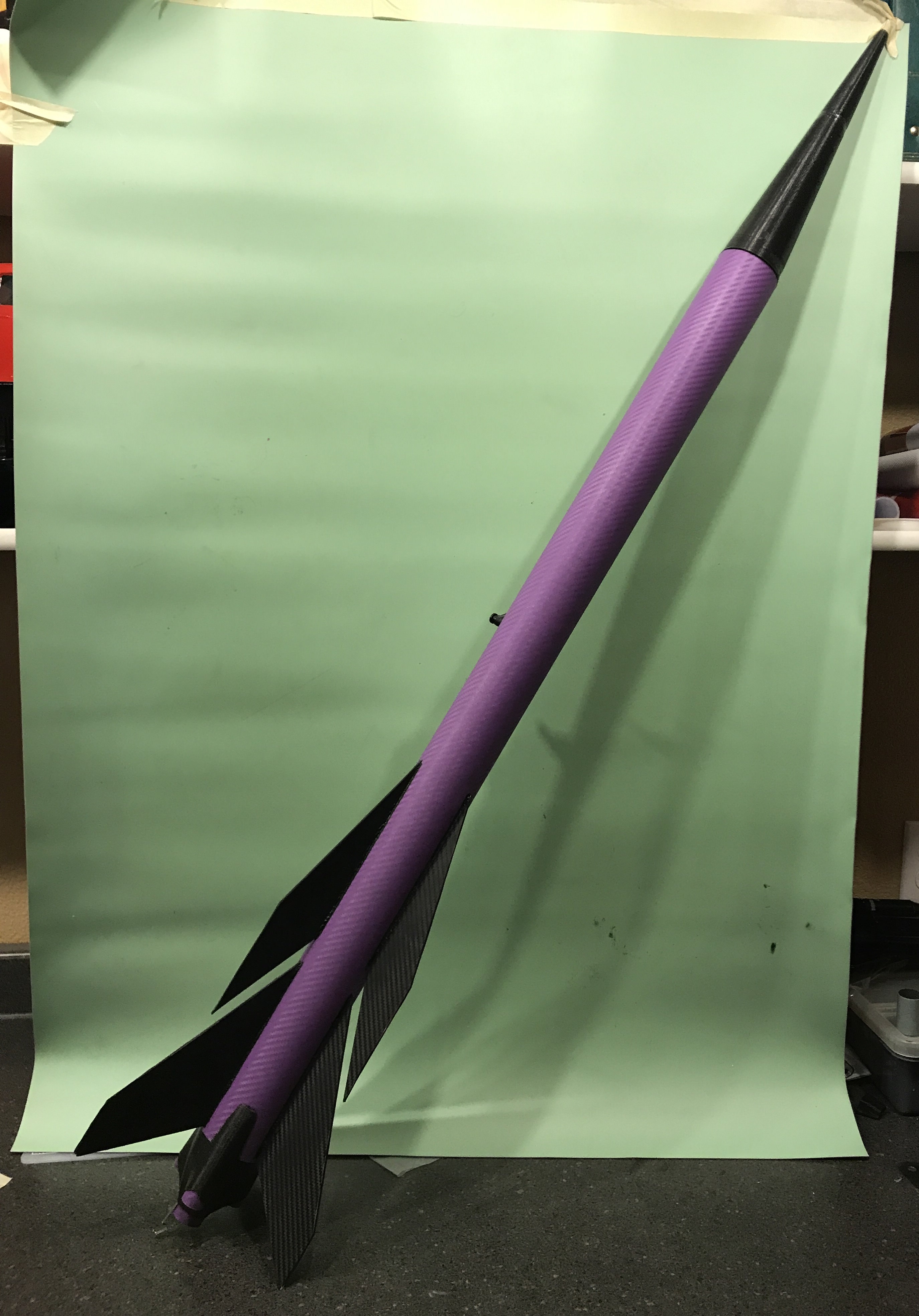

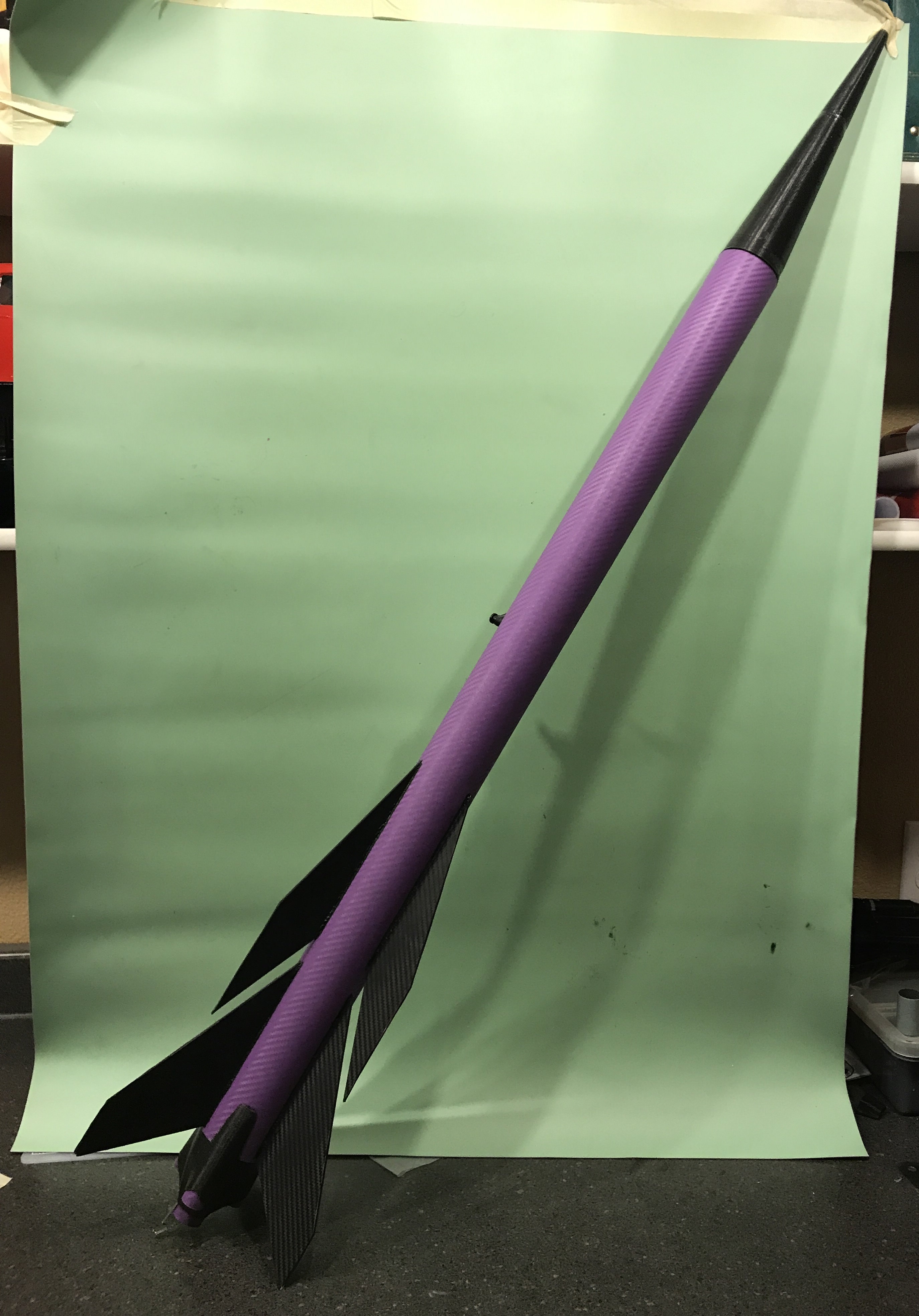

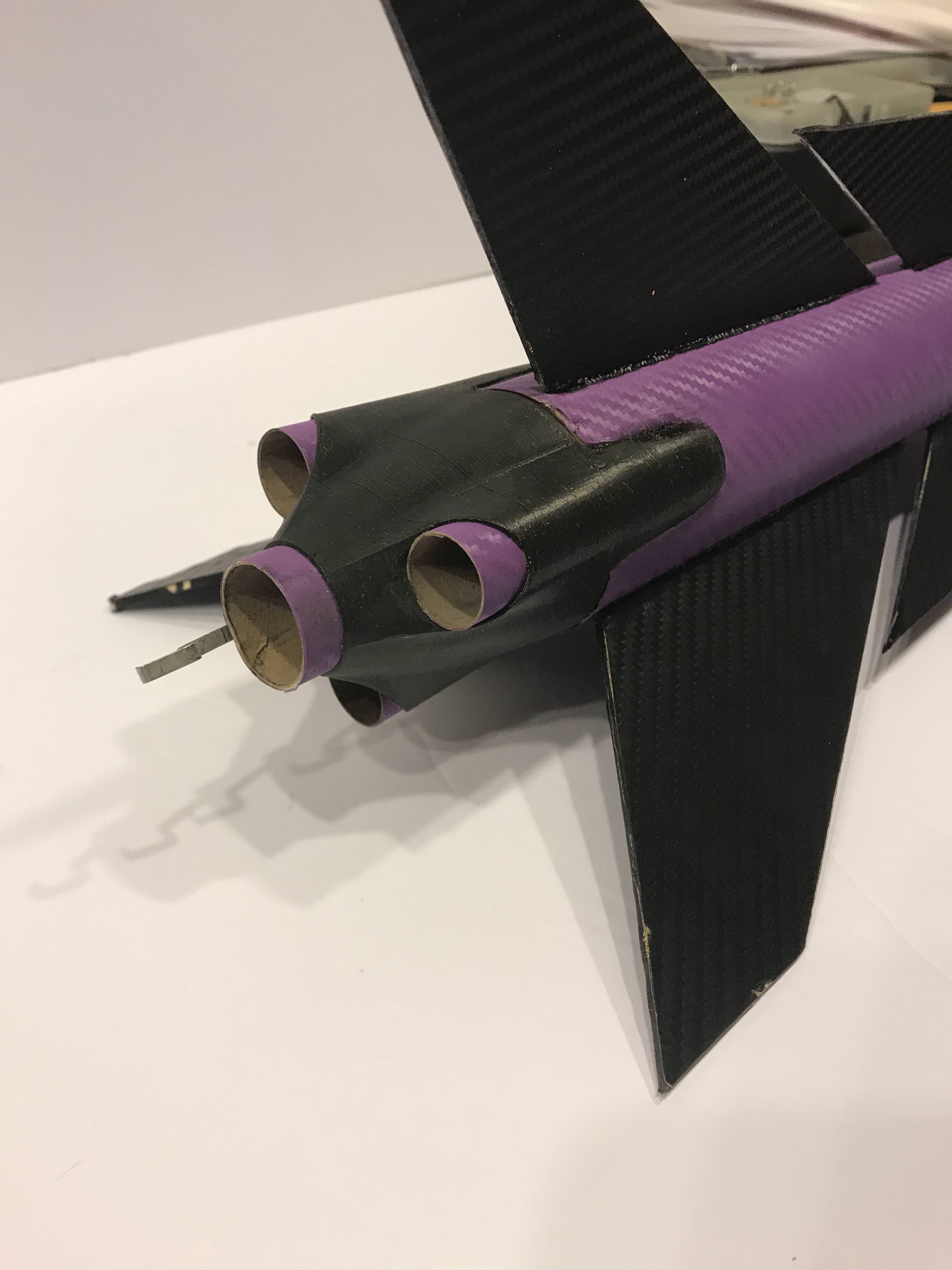

So, I call this one Big Purple.

Full length LOC 2.14 air frame

Custom 3D printed nose cone, tail cone and rail button stand offs.

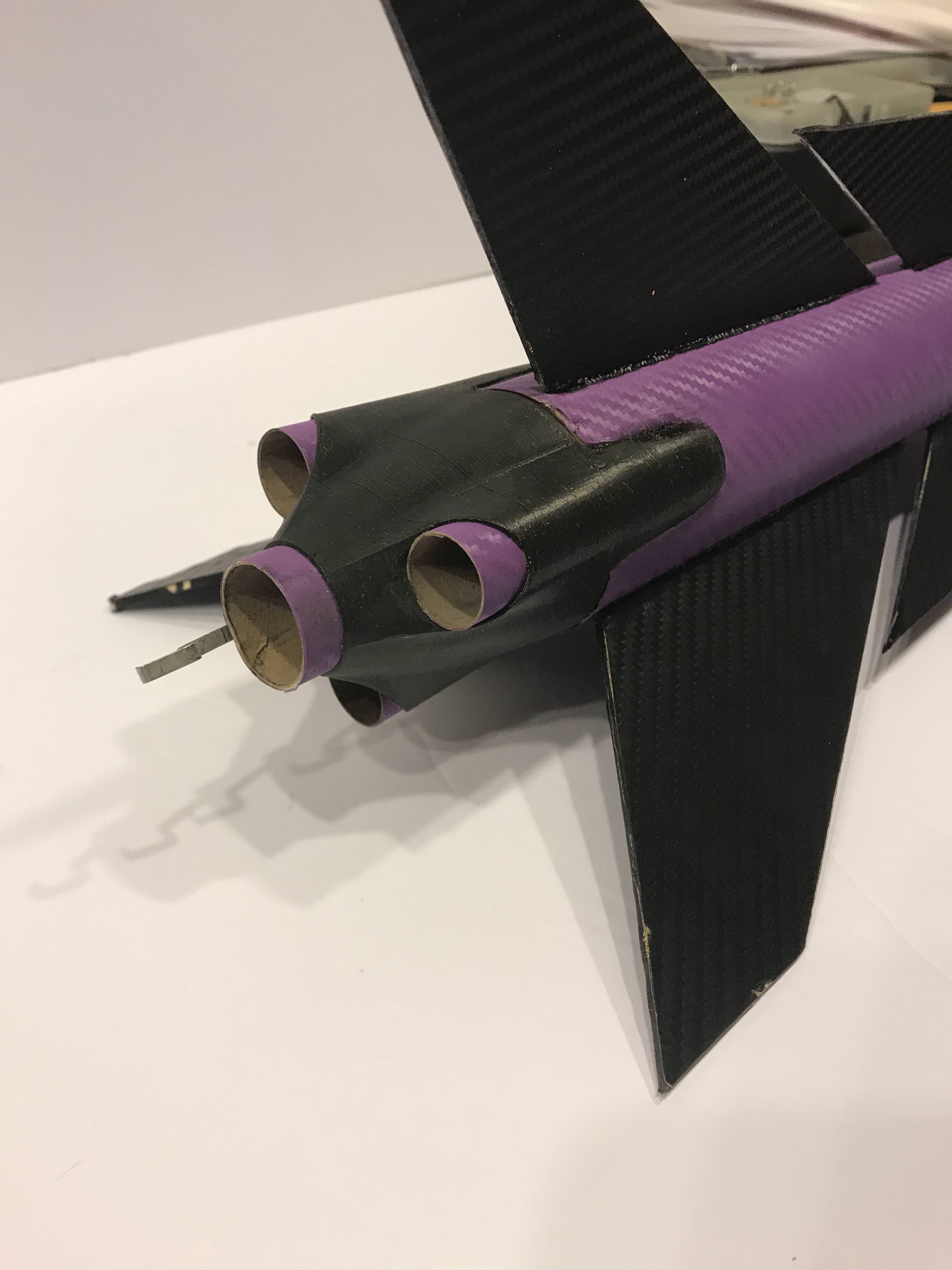

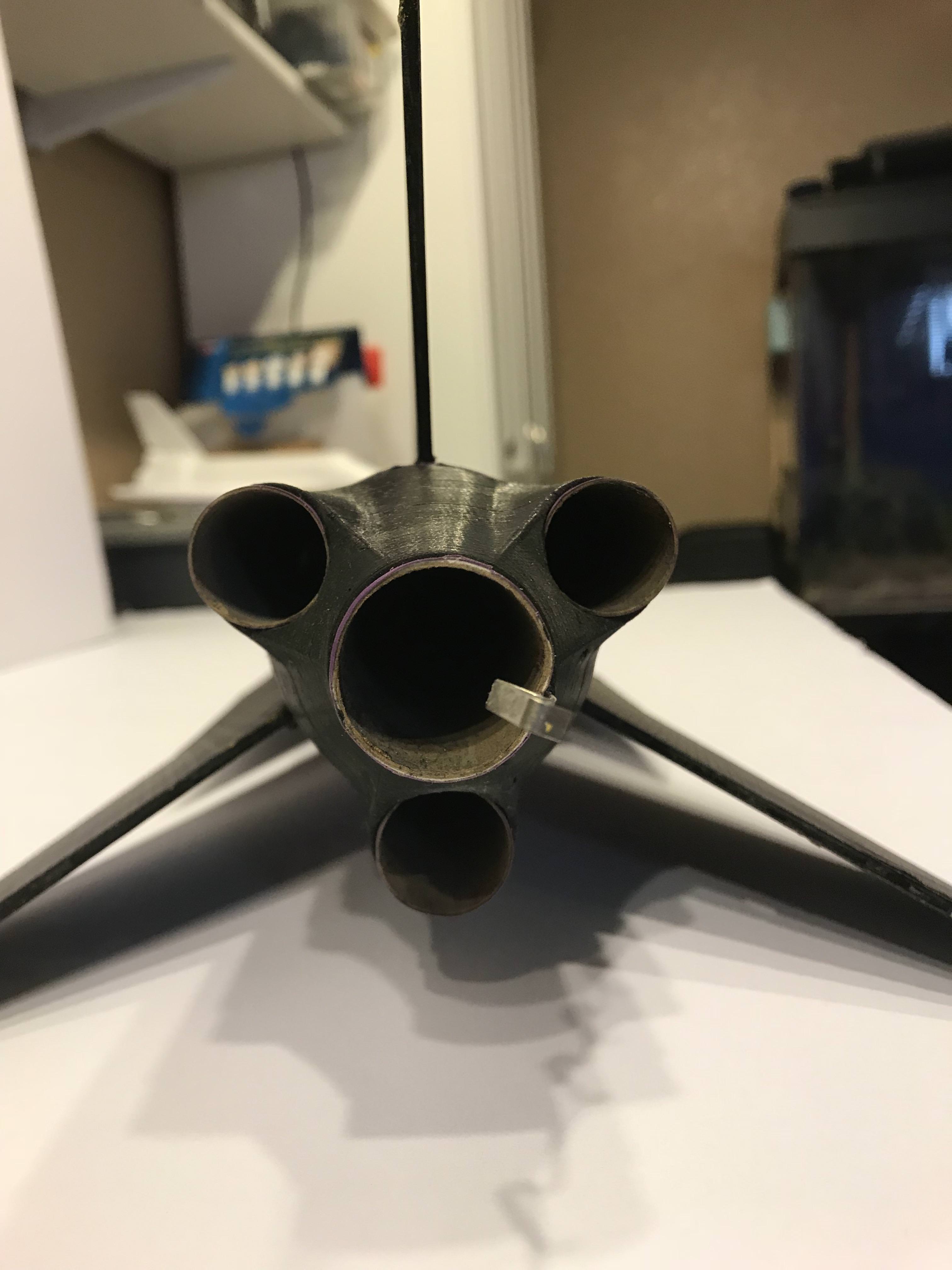

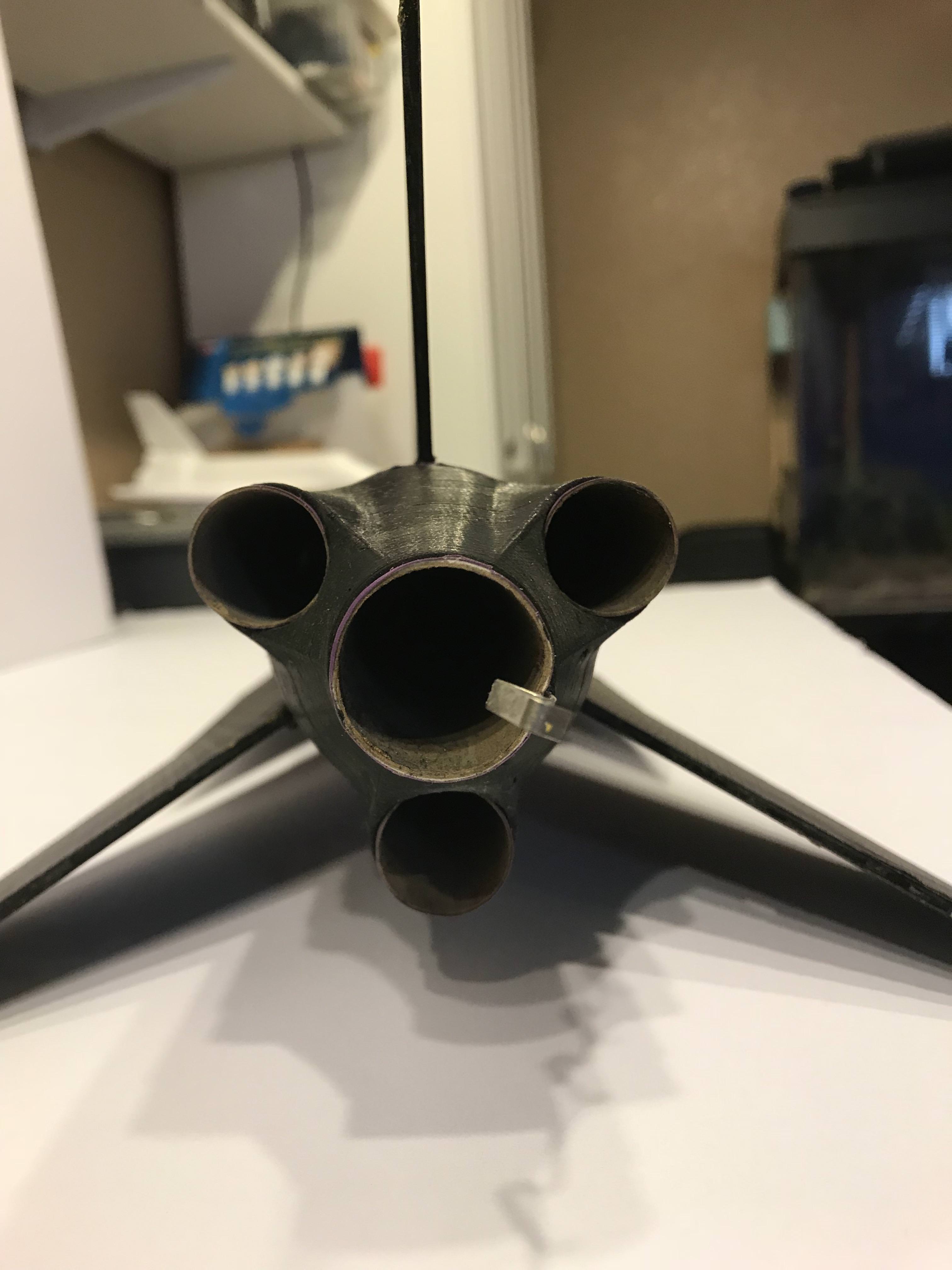

The 4 engine cluster is 3 canted 18mms and one center 24mm

The 3 canted motors are plugged and the 24mm is used full through for deploy

Notice the close up of the tail cone - My son did some fantastic 3D modeling there to pull off all the angles and curves.

The canted motors angle matches to the center of mass within a cm or 2 - in an effort for really straight flight.

The entire body and fins are covered in carbon fiber look vinyl wrap. - not a single drop of paint

First flight the center 24mm didn't fire (yep, not enough boost and no parachute deploy) The entire rocket survived (nose cone included).

Flight 2 was all engines go! (3-C6s and 1-D12)

[video=youtube;SfXK_yujDG8]

Full length LOC 2.14 air frame

Custom 3D printed nose cone, tail cone and rail button stand offs.

The 4 engine cluster is 3 canted 18mms and one center 24mm

The 3 canted motors are plugged and the 24mm is used full through for deploy

Notice the close up of the tail cone - My son did some fantastic 3D modeling there to pull off all the angles and curves.

The canted motors angle matches to the center of mass within a cm or 2 - in an effort for really straight flight.

The entire body and fins are covered in carbon fiber look vinyl wrap. - not a single drop of paint

First flight the center 24mm didn't fire (yep, not enough boost and no parachute deploy) The entire rocket survived (nose cone included).

Flight 2 was all engines go! (3-C6s and 1-D12)

[video=youtube;SfXK_yujDG8]

Last edited: