Mrappe

Active Member

- Joined

- Jul 21, 2017

- Messages

- 25

- Reaction score

- 0

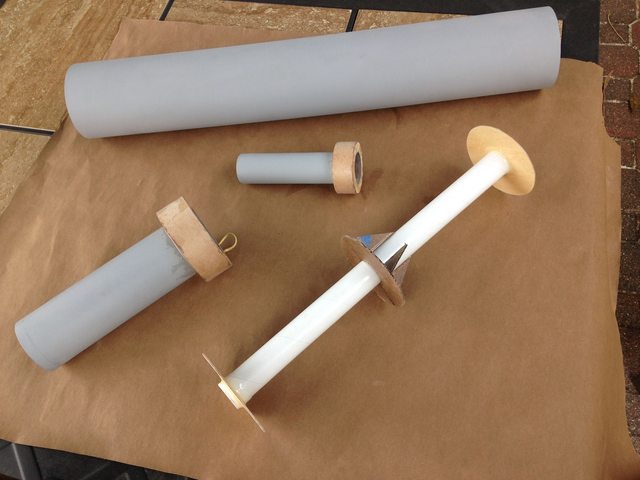

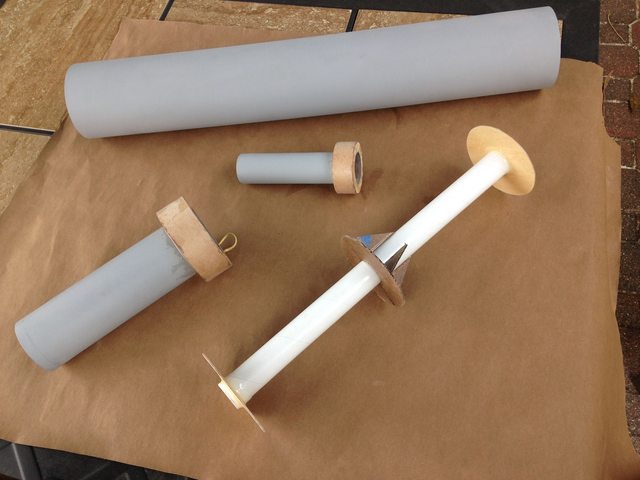

I have started working on my old kit by changing the motor mount to a 29 mm and making all of the rings and bulkheads out of 1/16 aircraft plywood and attaching them with CA and slow cure epoxy. The only exception is the center (gusseted) mount which I cut out of a 1/16 corrugated plywood box and soaked with very thinned down epoxy to stiffen it. The middle mount was not necessary I think but it helps keep the BT stiffer in between the others. I plan to fly it on Es and Fs because of the added weight due to the Sirius Rocketry's molded components. I have not attached the motor mount to the body tube and am concerned about installing it so far foreward. It seems like it could be a problem with the exhaust burning the tail of the rocket. Especially with larger motors.

Mike

Mike