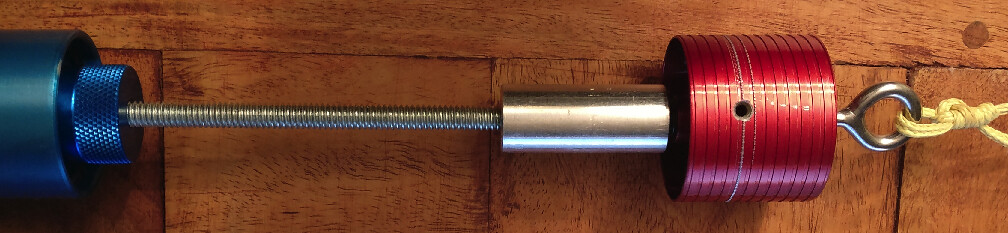

As per jhbarr the adapter just screws into the end of the CTI charge cup. Below are pics of my 54 and 38mm adapters, which as you can see by the last pic vary in depth and the plug that fits into the hole in the base of the charge-well. I found the easiest way to screw them in was using a socket wrench with a 22mm socket, otherwise you can misalign them very easily.

View attachment 331341View attachment 331342View attachment 331343View attachment 331344View attachment 331345View attachment 331346

Total noob here. How is using one of those superior to just epoxying over the delay hole? Seems like it adds mass for no reason?