My first two rockets flew brilliantly this weekend, an Amazon and a Crossfire, and now I'm looking to challenge myself.

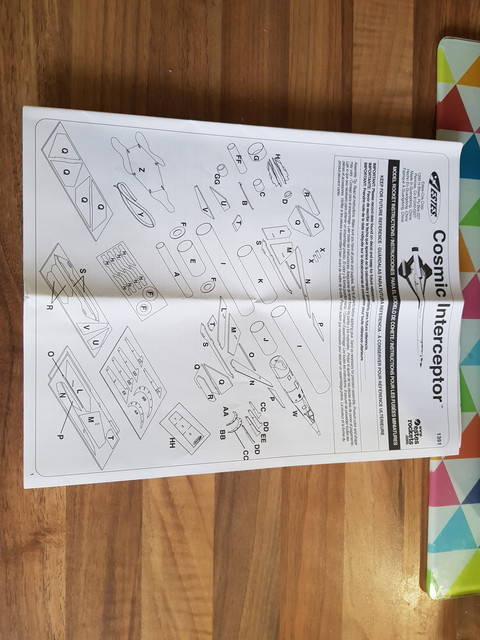

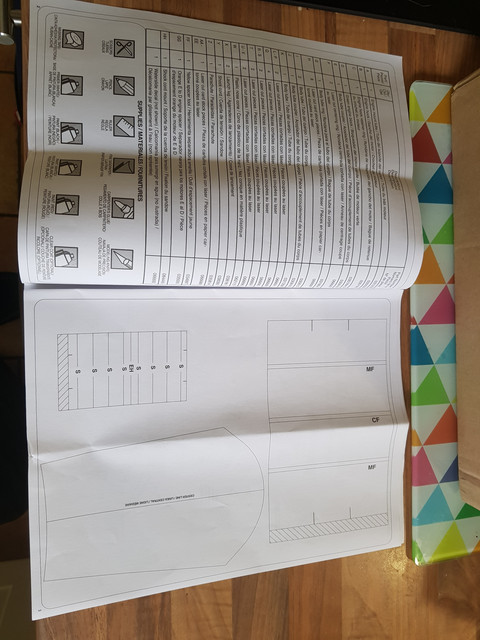

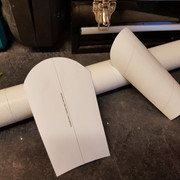

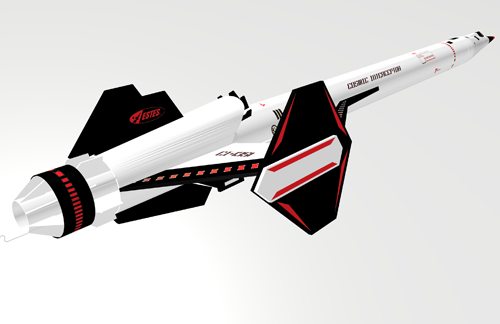

I've liked the look of a Cosmic Interceptor.

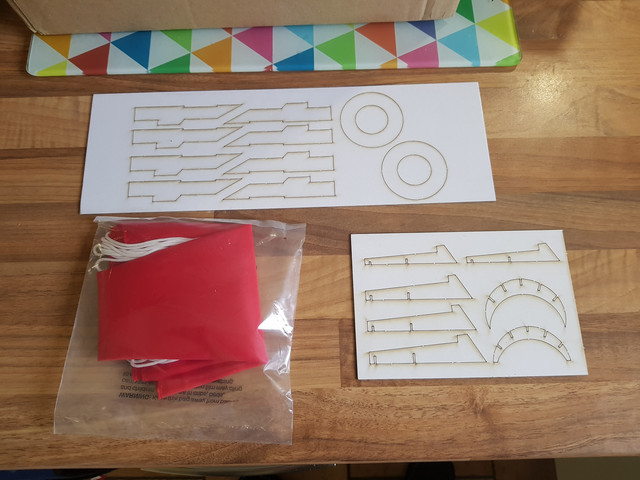

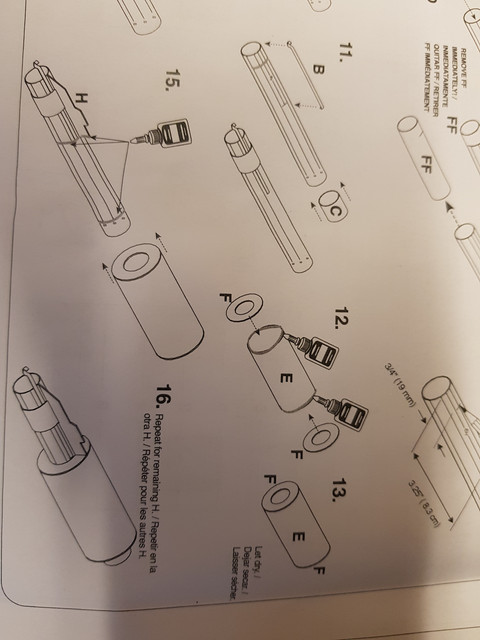

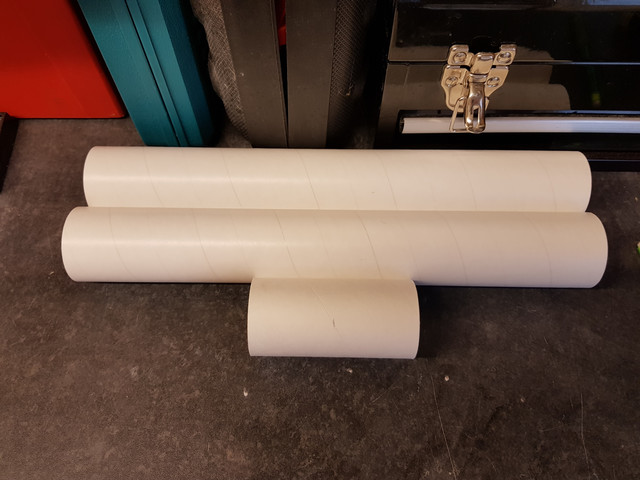

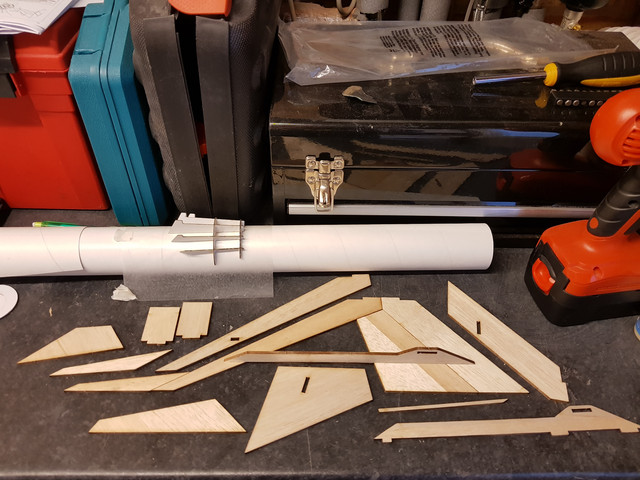

It was either that or a QCC explorer for my next kit, and this is the one my local vendor had at the field today! It can take 24mm D or E motors, with a stuffer ring for the shorter Ds, and I was recommended a pair of D12-3s for it. I'm told it can also fit Cesaroni Pro24s. So this is my next build.

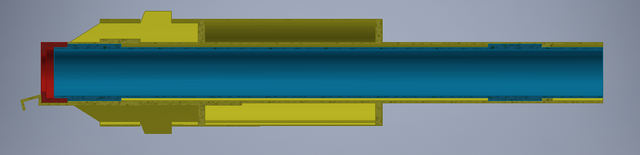

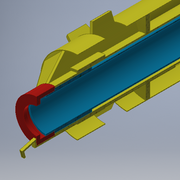

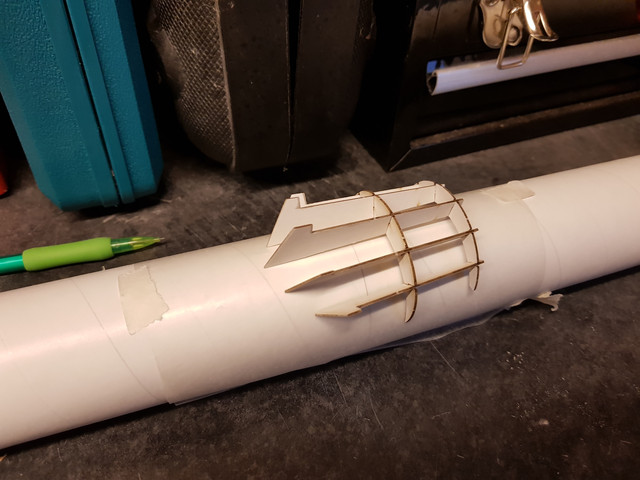

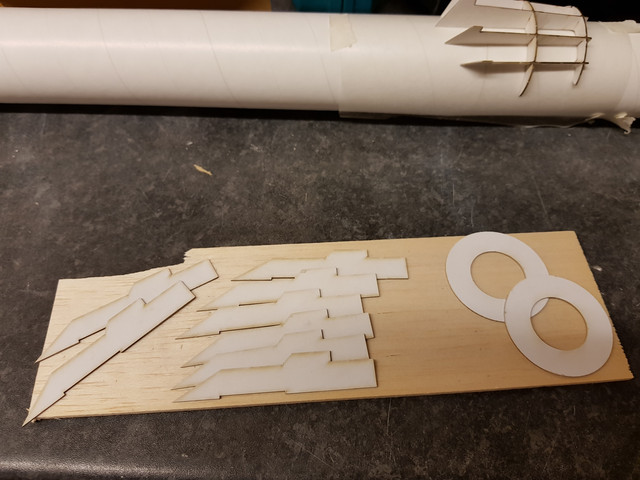

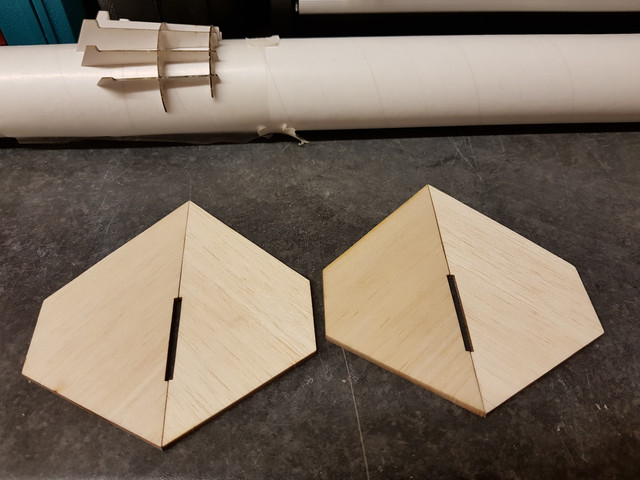

Before I start, I have an option: it looks like a relatively easy mod to 29mm motors, with an adaptor back to 24mm. Trim the strakes, larger motor tube. The original 24mm motor tube can be fitted with some balsa strake extensions an extra motor clip, and retained by the original clip on the new 29mm tube. It should retain its lines at the rear quite nicely. Is this mad? I've got no way to check the stability with that extra mass moved backwards.

Does anyone know if there's an Open Rocket file of the Cosmic Interceptor somewhere?

I've liked the look of a Cosmic Interceptor.

It was either that or a QCC explorer for my next kit, and this is the one my local vendor had at the field today! It can take 24mm D or E motors, with a stuffer ring for the shorter Ds, and I was recommended a pair of D12-3s for it. I'm told it can also fit Cesaroni Pro24s. So this is my next build.

Before I start, I have an option: it looks like a relatively easy mod to 29mm motors, with an adaptor back to 24mm. Trim the strakes, larger motor tube. The original 24mm motor tube can be fitted with some balsa strake extensions an extra motor clip, and retained by the original clip on the new 29mm tube. It should retain its lines at the rear quite nicely. Is this mad? I've got no way to check the stability with that extra mass moved backwards.

Does anyone know if there's an Open Rocket file of the Cosmic Interceptor somewhere?