billdz

Well-Known Member

- Joined

- Feb 10, 2017

- Messages

- 1,377

- Reaction score

- 121

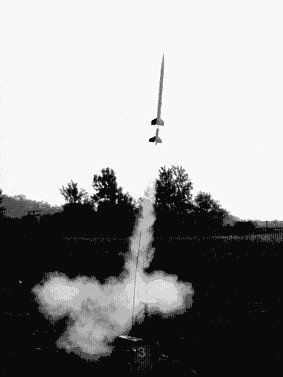

I brought my Klima Delphinus two-stage rocket back from Europe but I'm not sure if it can fly on Estes motors. On all the Estes two-stagers I have seen, the booster and the upper stage motors are connected together with tape. That's not possible with the Delphius, there's over a 1" gap between the motors (the Klima booster lights a fuse on the upper stage booster). I could tape a cardboard sleeve between the motors.

Anyone know if the Estes boosters can ignite the upper motor without a direct taped connection?

Anyone know if the Estes boosters can ignite the upper motor without a direct taped connection?