conwayte

Well-Known Member

- Joined

- Nov 29, 2016

- Messages

- 68

- Reaction score

- 0

Hello!

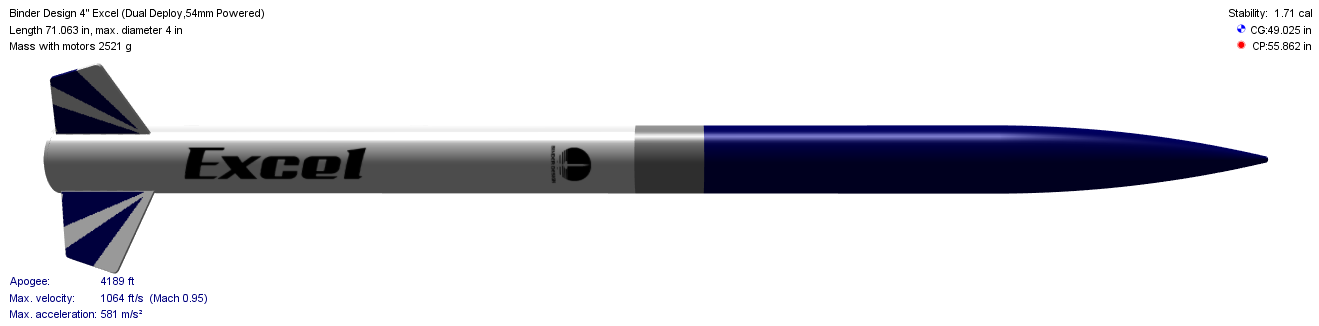

Im currently building a Binder Design Excel w/ Dual Deploy. My plan is to use this for my Level 1 certification when the club launch season starts up. Possibly use it for Level 2 later on as well?

After reading through many of the existing Excel build threads, I decided to go with the 38mm motor mount. There are enough loads from the various manufacturers in that diameter to get me up through level 2 if thats the direction I decide to go (I have a feeling I may end up building something new for L2 but who knows?)

My plan is to build basically stock--the one exception is the addition of a Onebadhawk harness. Part of my decision-making process included the business's presence on TRF. Its nice to get a feel for them through their posts. Mike at Binder and Teddy at Onebadhawk are both great to work with and are as helpful as their posts suggest.

The Excel arrived within days, was excellently packaged and Im very impressed with the instructions--very thorough. Separate instructions for each sub-component as well--avbay, motor retainer, etc.

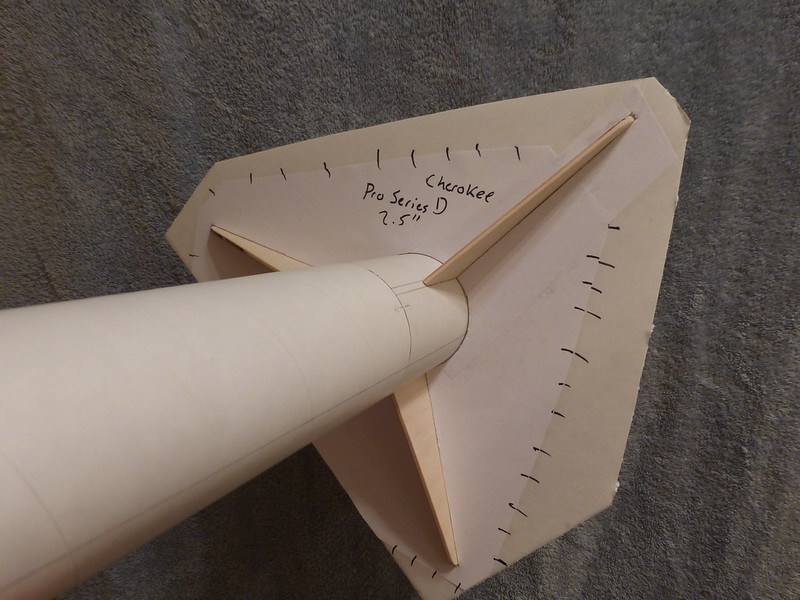

First picture is assembly of the motor mount. Im using some hardware store 15 minute epoxy for most of this. I scuffed up the glassine layer and am using my high-tech pressure inducing devices for clamping the aft centering ring and thrust ring .

.

Im currently building a Binder Design Excel w/ Dual Deploy. My plan is to use this for my Level 1 certification when the club launch season starts up. Possibly use it for Level 2 later on as well?

After reading through many of the existing Excel build threads, I decided to go with the 38mm motor mount. There are enough loads from the various manufacturers in that diameter to get me up through level 2 if thats the direction I decide to go (I have a feeling I may end up building something new for L2 but who knows?)

My plan is to build basically stock--the one exception is the addition of a Onebadhawk harness. Part of my decision-making process included the business's presence on TRF. Its nice to get a feel for them through their posts. Mike at Binder and Teddy at Onebadhawk are both great to work with and are as helpful as their posts suggest.

The Excel arrived within days, was excellently packaged and Im very impressed with the instructions--very thorough. Separate instructions for each sub-component as well--avbay, motor retainer, etc.

First picture is assembly of the motor mount. Im using some hardware store 15 minute epoxy for most of this. I scuffed up the glassine layer and am using my high-tech pressure inducing devices for clamping the aft centering ring and thrust ring