So,

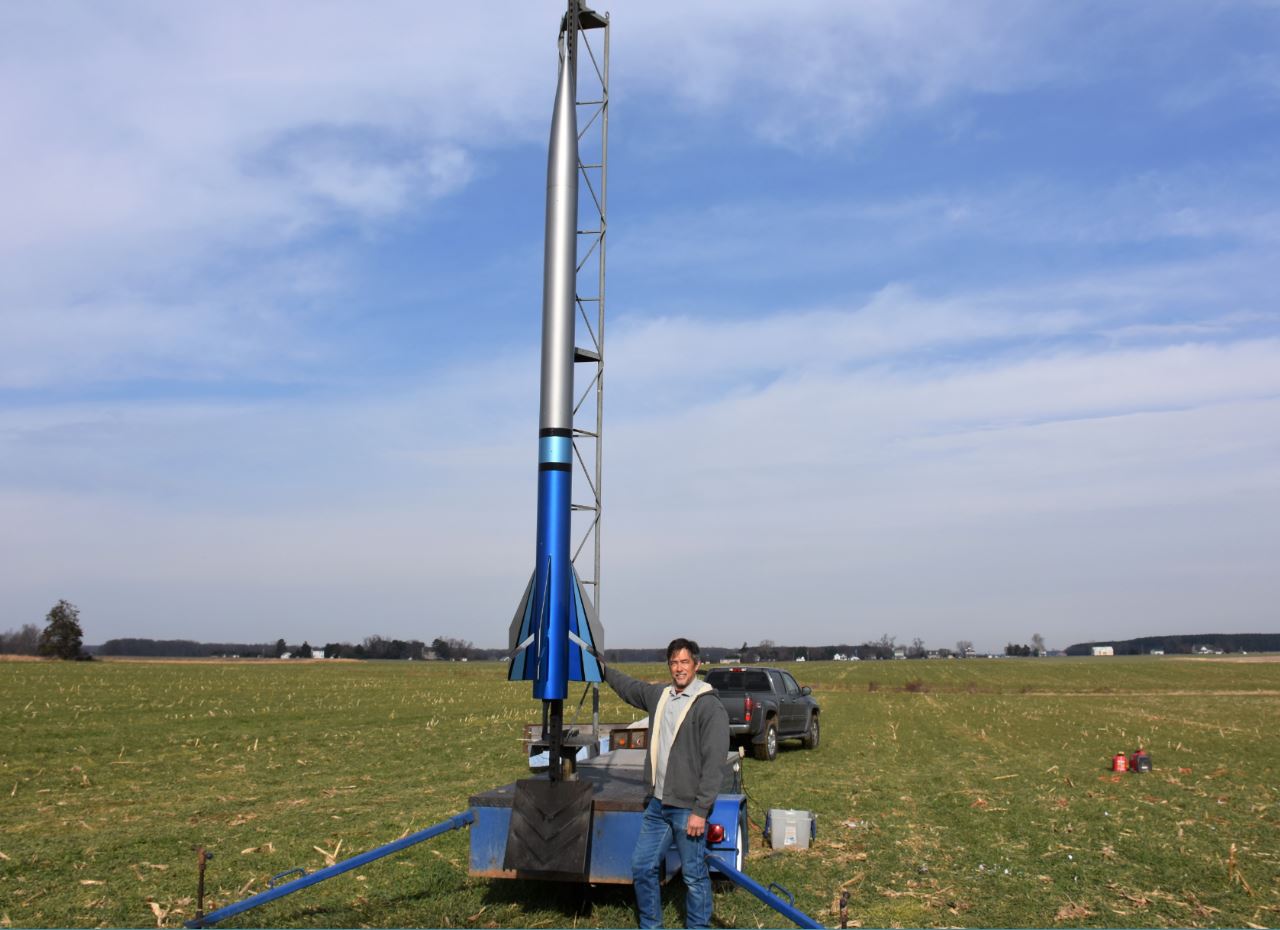

I got a 8" x 10' 6" rocket that's still nekid after 2 flights... What would it take to bribe you to paint it?

No, never mind... With a paint job that beautiful, I'd be too afraid to take it out of the house.

Seriously, that looks friggen awesome! Well done.

Considering it takes Nathan months to finish a paint job, you'd have to cash in your retirement. :wink:

Looking forward to your flight, Nathan (if it's on a Saturday). Looks incredible.