Too much fraternizing (posting)--the death knell of so my L3's.

You...:no: Growwwwwl...:dark:

Matt, as i mentioned the other night by phone i will be watching your build thread with excitement from afar as i normally don't wander over here too much.

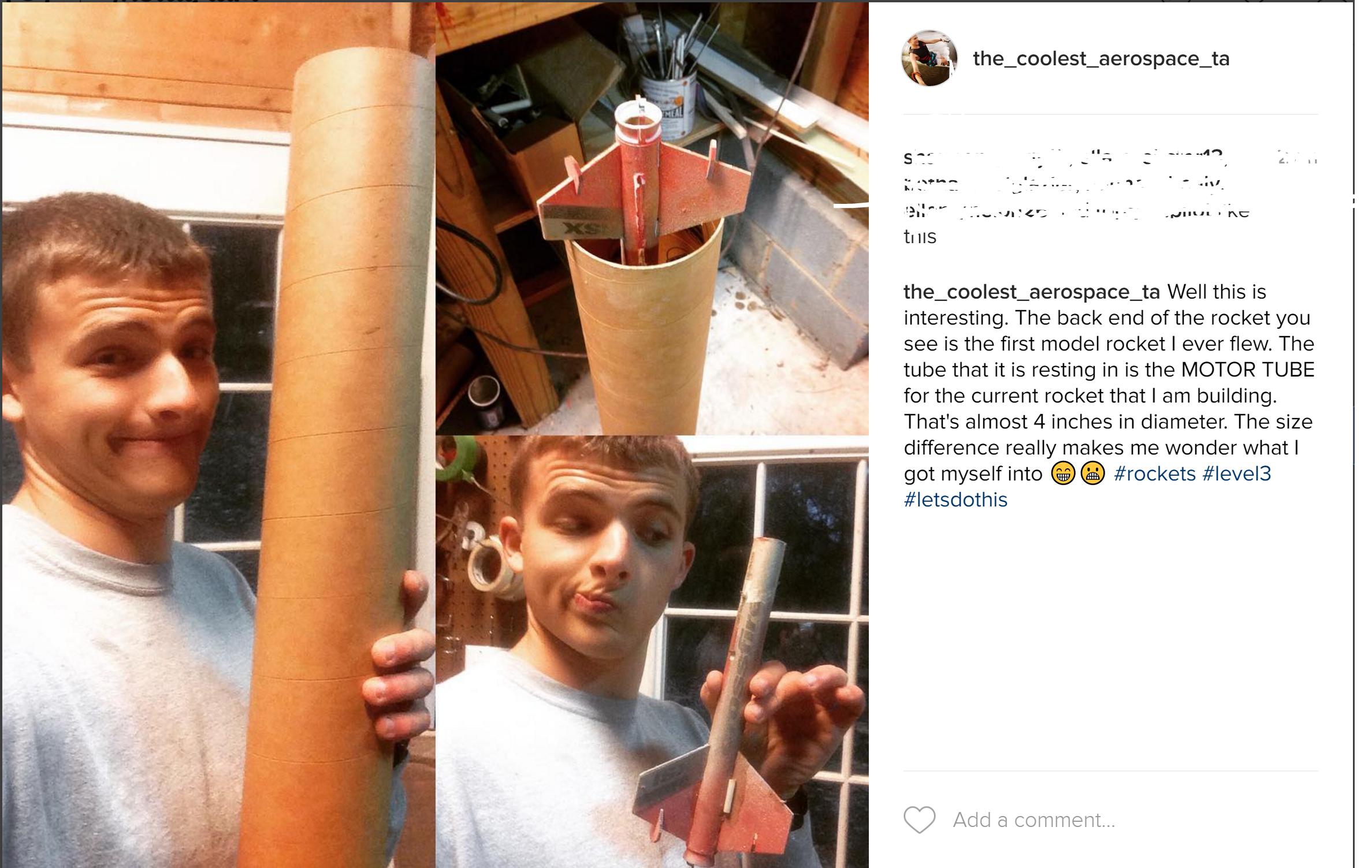

1. I think you've picked a great design that utilizes FOUR fins.

2. I like the fact that even though you could build it in fiberglass that your going "Old School" here...

3. You've already upgraded the original idea of a 75mm motor mount to a 98mm...That i also agree will open many more opportunities (motor wise).

4. Fully expect that even though you have an idea about the projected mass now...Plan that it will come in a little heavier in the end.

5. Be prepared to add reinforcement in some areas. (Tubing, Fins and, Coupler above what is planned now) So as to give this design a higher chance of longevity.

I have three recommendations right now that i want you to consider-

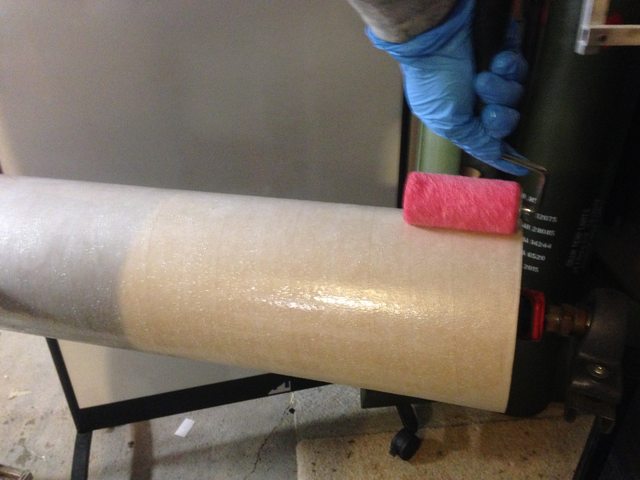

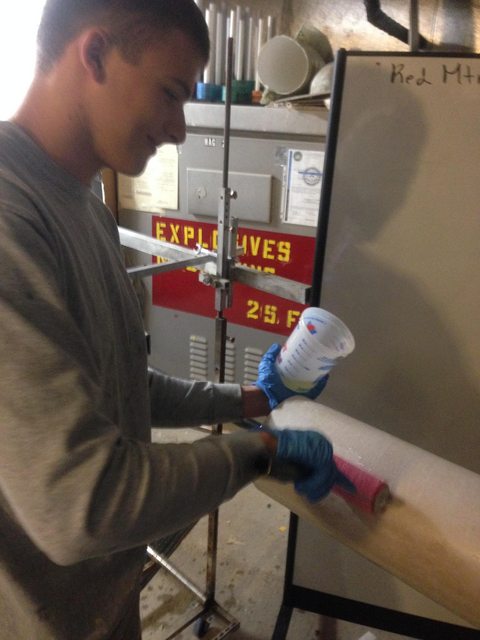

Put another layer of glass over the fins.

Prepare that you may choose another motor (Not to knock you down) to meet your flight performance goals if..if this thingy gets heavy.

When it comes to your deployment charges and, testing them. I want to see a noticeable separation NOT a little *pop*...So some thought has to go into this.

I fly 99% of my flights with the same Altimeters riding side by side...set at the same settings.

NO ONE has ever proven to me exclusively that using two different: Brands, Styles or settings ALWAYS works to the best.

When you consider the design of your AV Bay, vent holes, matches and type/compaction of BP...things don't always work the same in a non Six Sigma world of model rocketry. Your design will have to be robust enough to handle whatever happens when those charges fire...and, i would never go beyond two seconds of delay past apogee.

Whenever i prep a rocket (and, i know you will have this mindset) the *funny* comes off. You have to consider many things and, adhere to the fact that what your doing is serious business. You throw in the factor that your safety and, the lives of the people and, the damage incurred to the property around you are directly affected by decisions you make. Some things can go beyond your control but, you realize that by stepping up to L3 levels you have to see the "Big Picture".

I really hate using that analogy but, you have to remember that i spent many years screwing together Nuclear ICBMs for the USAF and, everyday i went to work...that responsibility was drilled into me. Mistakes we could make were very harsh to pay for.

Keep up the good work and, i will check in periodically mostly by PM, text or phone...Consider and, take the advice of your peers with notice but, in the end "Uncle Jimmy" and, i will be more than happy to offer our advice on any issue you may have...Time will go by fast, LDRS 36 will get here sooner than you think but, when you stand out on that field i want you to know that you have done everything within ability to build your best rocket ever and, be able to explain WHY its that way.

I know you will...