Peter Olivola

Well-Known Member

- Joined

- Oct 10, 2010

- Messages

- 667

- Reaction score

- 3

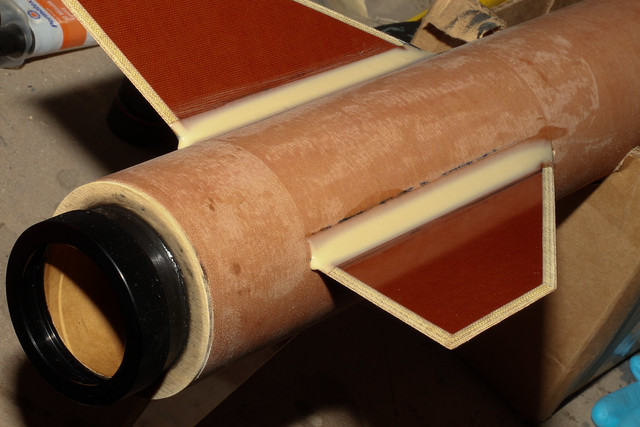

This assumes their sole purpose is to reinforce the fin attachment. I've found that slotting body tubes weakens the airframe considerably and tying them to the fins at each point of contact replaces airframe integrity. Fin flutter can cause airframe failure, not just fin failure.

Exactly. They are completely unnecessary. The fact that you're going through the wall to an internal motor mount pretty much guarantees you'll stay below Mach 1.5 in most cases. And while all the leverage arguments above are technically correct and come with a pretty picture they're mitigated by the fact that you'd still bond the fin to the motor mount even IF you didn't run internal fillets. So you'll still have two bonded points of contact between the fin and rocket, one on the motor mount, the other on the fillets on the external airframe. So the leverage arguments are made moot by that fact. And if there's enough leverage to separate the two bonds per fin, I'm pretty sure you're rocket is already in a world of hurt.