Ok, since there just doesn't seem to be any complete build threads, I'm going to give on a try for this beast of a rocket. Let's try to break the trend, and get one done!

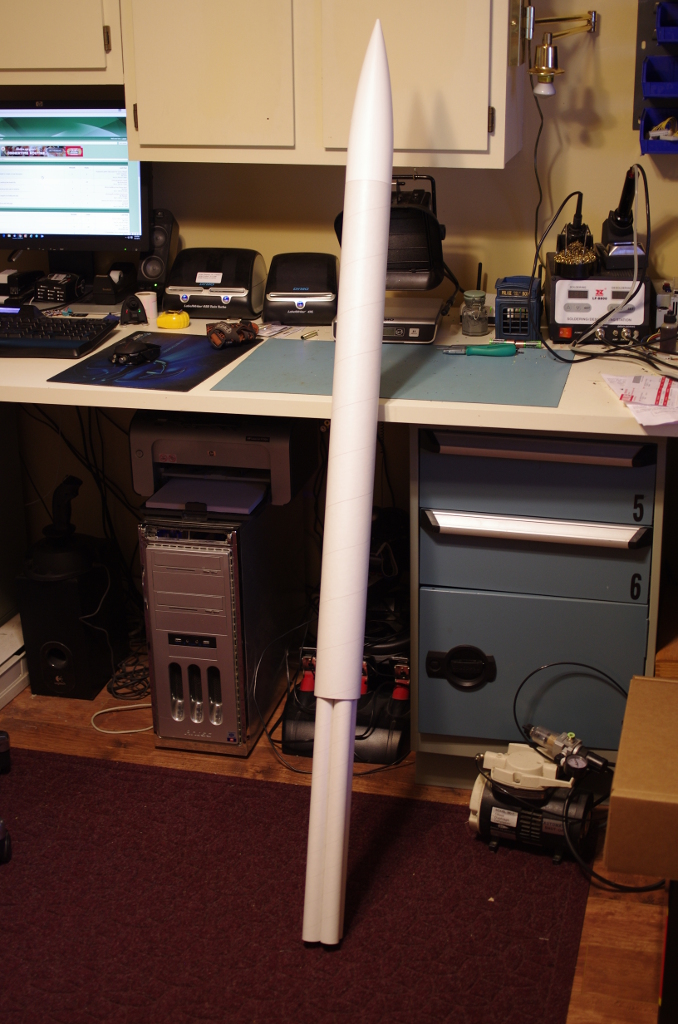

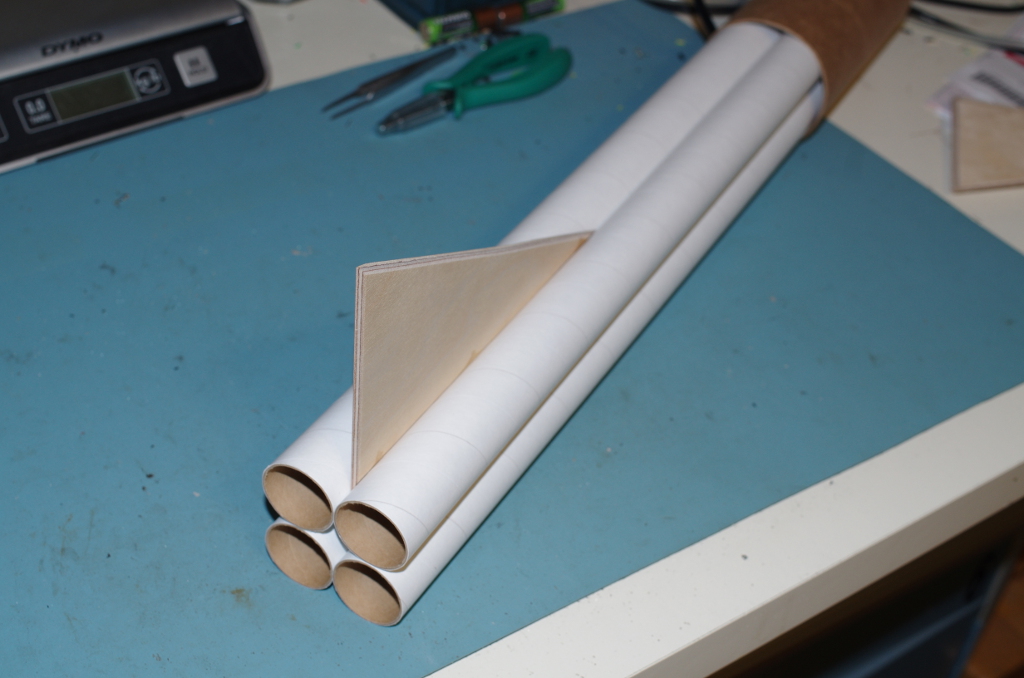

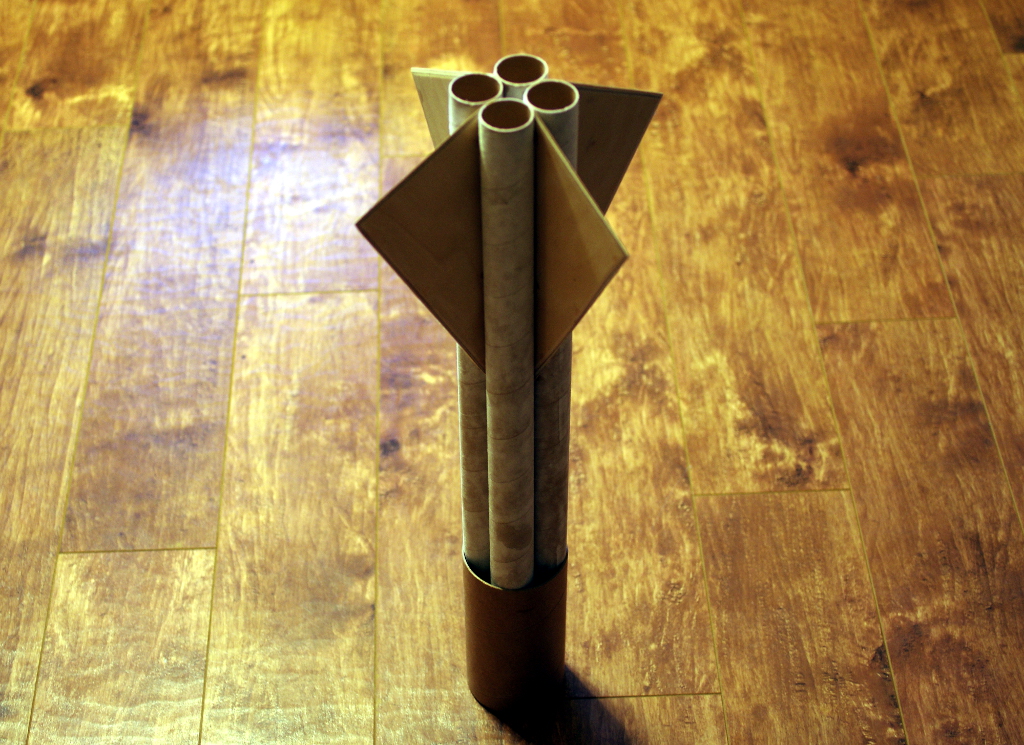

Anyway, the LOC 4-29SS, for a quick rundown of the kit before we get going. This is a 3" body tubed mid to late 90's design from LOC, and is a cluster-only flyer. The 4-29 part of the name stands for the 4x 29mm motor mounts that make up the lower section of the rocket. The SS? Strangely enough it stands for "Slip/Slide". It's made to be easily separated into the lower and upper sections, and the instructions say you can get additional lower halves for pre-loading.

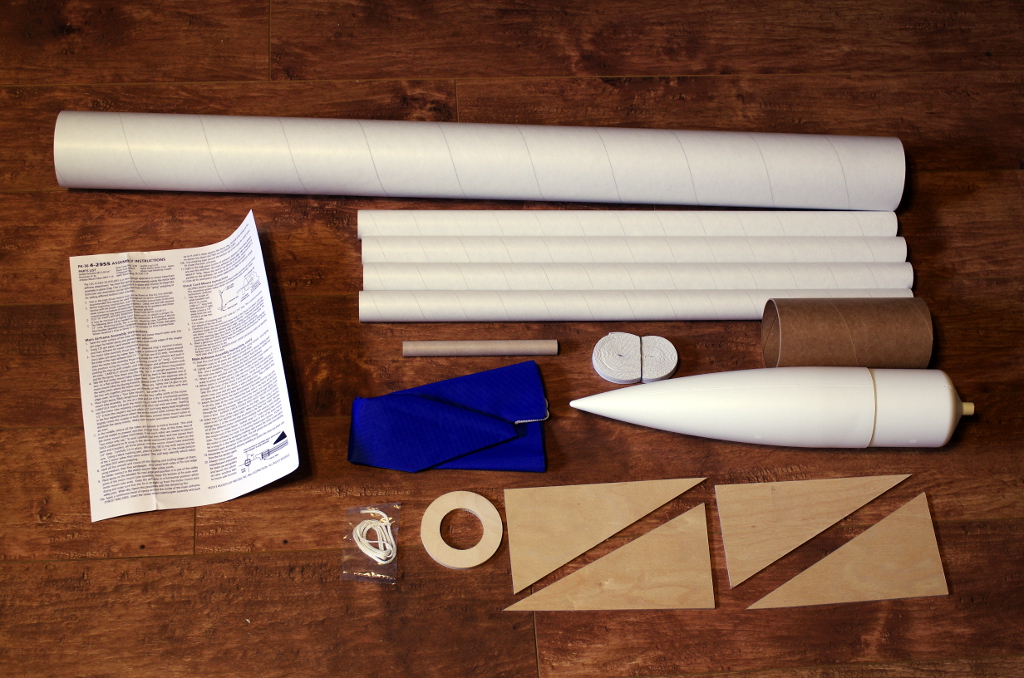

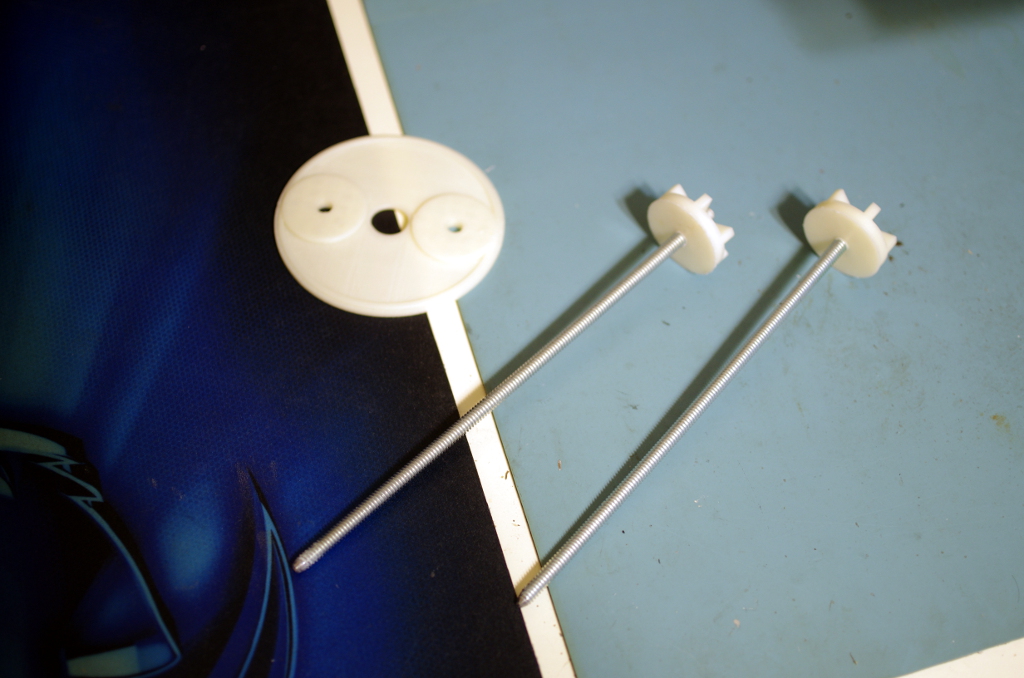

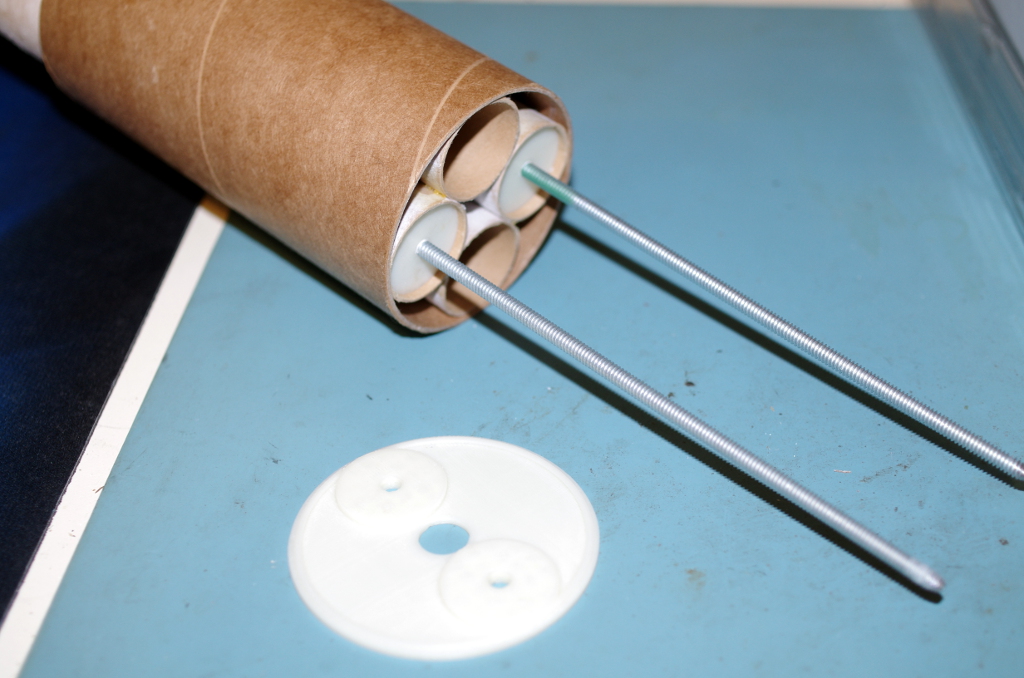

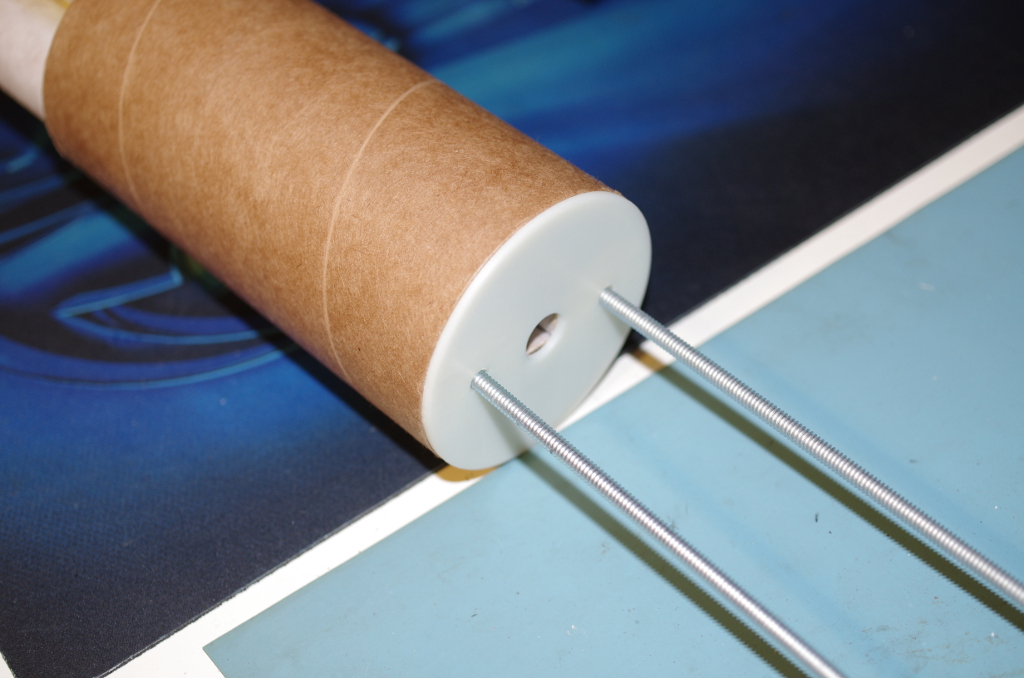

The kit comes with everything you need for a basic flyer. Plastic nose cone, 3" upper tube, 4x29mm lower tubes, 36" nylon chute, elastic shock cord, fins, plastic nose cone, launch lug, one coupler, and a thrust ring/bulkhead. Motor retention in the instructions is via friction fit. Recommended motors are 4 F's or 2 G's. No decals are included, and instructions are just text with very few drawings of limited use. No decals are included, which is a shame because the artwork on the bag card is pretty impressive.

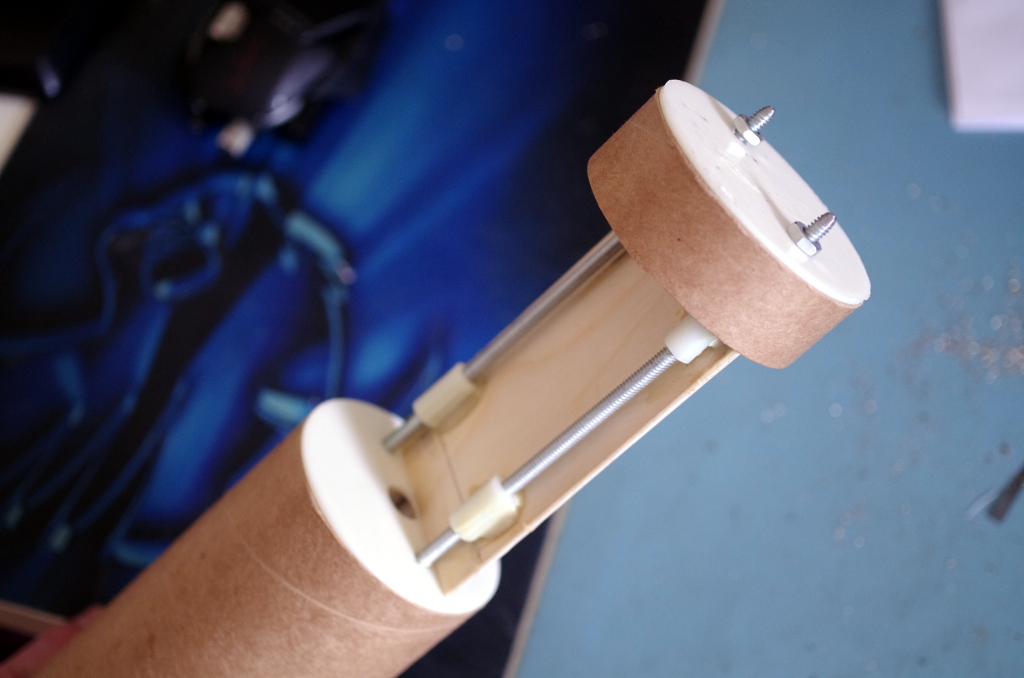

My plan on this one is to build it for potential air starts, dual deploy, and no way in hell I'll be doing friction fit (I'm really bad at it). I'll be using my trusty Raven for altimeter and starter duty, and since I'll probably need the nose weight, I'll see if I can get my eggfinder in there too. Will be a slow start, been really busy this week, but I need to get some rocketry done.

And since I'm sure somebody will ask .... I don't plan on doing a Stovi just yet. For those who don't know, that's a similar kit from LOC but with 7 x 24mm motors.

Anyway, the LOC 4-29SS, for a quick rundown of the kit before we get going. This is a 3" body tubed mid to late 90's design from LOC, and is a cluster-only flyer. The 4-29 part of the name stands for the 4x 29mm motor mounts that make up the lower section of the rocket. The SS? Strangely enough it stands for "Slip/Slide". It's made to be easily separated into the lower and upper sections, and the instructions say you can get additional lower halves for pre-loading.

The kit comes with everything you need for a basic flyer. Plastic nose cone, 3" upper tube, 4x29mm lower tubes, 36" nylon chute, elastic shock cord, fins, plastic nose cone, launch lug, one coupler, and a thrust ring/bulkhead. Motor retention in the instructions is via friction fit. Recommended motors are 4 F's or 2 G's. No decals are included, and instructions are just text with very few drawings of limited use. No decals are included, which is a shame because the artwork on the bag card is pretty impressive.

My plan on this one is to build it for potential air starts, dual deploy, and no way in hell I'll be doing friction fit (I'm really bad at it). I'll be using my trusty Raven for altimeter and starter duty, and since I'll probably need the nose weight, I'll see if I can get my eggfinder in there too. Will be a slow start, been really busy this week, but I need to get some rocketry done.

And since I'm sure somebody will ask .... I don't plan on doing a Stovi just yet. For those who don't know, that's a similar kit from LOC but with 7 x 24mm motors.