Crash-n-Burn

Well-Known Member

- Joined

- Aug 14, 2014

- Messages

- 377

- Reaction score

- 1

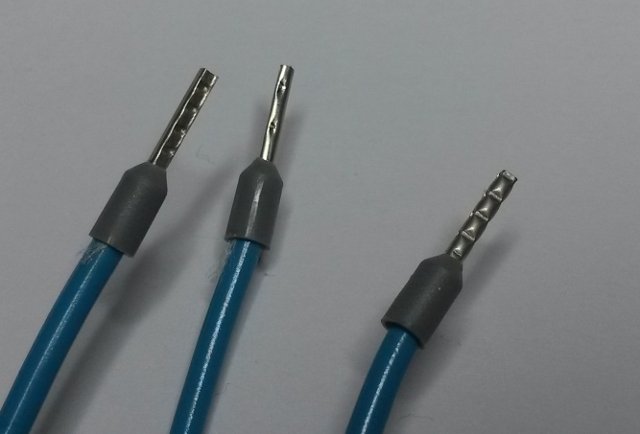

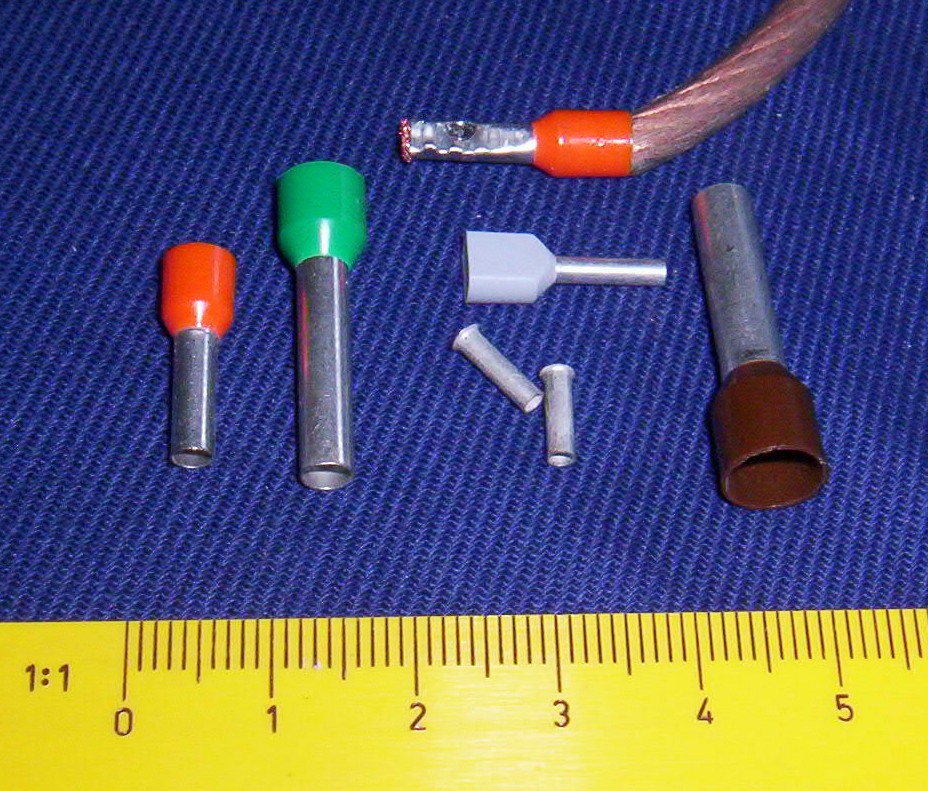

I noticed that the RRC2+ instructions recommend stranded wire (20/22 awg) for all connections. I didn't have any so I recycled some e-match wire, which is single-strand copper. Everything looks good and the altimeter passed vacuum chamber testing. I know people wire e-matches directly to the board so this is not an entirely uncommon practice.

Does anyone know why they make the stranded reco? I'm not an electrician by trade but guess it is because stranded will spread and make a better contact in the pressure plates. Is that it or is there a more sophisticated reason?

Apologies if I butchered some of the wiring terms, hopefully I got the point across.

Does anyone know why they make the stranded reco? I'm not an electrician by trade but guess it is because stranded will spread and make a better contact in the pressure plates. Is that it or is there a more sophisticated reason?

Apologies if I butchered some of the wiring terms, hopefully I got the point across.