watermelonman

Well-Known Member

- Joined

- Sep 22, 2014

- Messages

- 2,597

- Reaction score

- 10

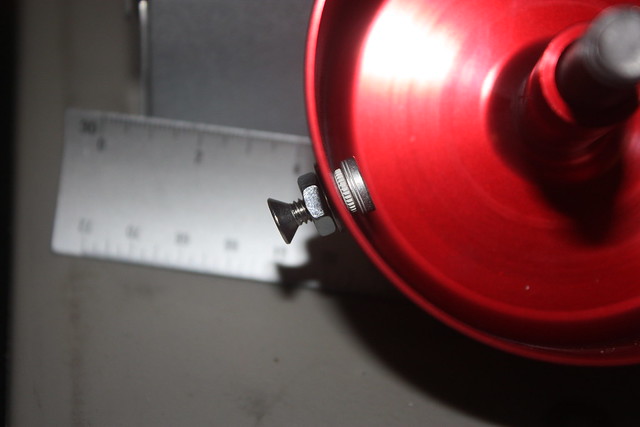

I love what I have been able to do with PEM nuts, but the little guys did not exactly come with instructions!

In most cases I have simply been drilling a hole sized correctly for the screw, and either adding a dab of glue or simply letting the backing sit there freely. However the glue is imperfect, and sometimes I do not want the threads falling away after screw removal.

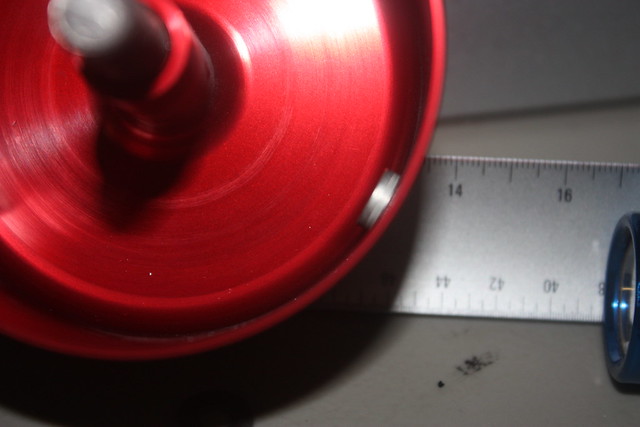

Is the intent to drill a size larger, so that the first depth wise half of the PEM nut can eat its way in? Or are the teeth simply supposed to do there job on the regular sized hole, and I should be setting them in place with more pressure? If drilling larger, is there a guide or chart to show how much larger?

Finally, will usage differ between materials, say fiberglass and aluminum?

Note that I eventually found the official guide for PEM nuts but it was focused on air ducts and concrete. I wanted to see what rocket builders do.

In most cases I have simply been drilling a hole sized correctly for the screw, and either adding a dab of glue or simply letting the backing sit there freely. However the glue is imperfect, and sometimes I do not want the threads falling away after screw removal.

Is the intent to drill a size larger, so that the first depth wise half of the PEM nut can eat its way in? Or are the teeth simply supposed to do there job on the regular sized hole, and I should be setting them in place with more pressure? If drilling larger, is there a guide or chart to show how much larger?

Finally, will usage differ between materials, say fiberglass and aluminum?

Note that I eventually found the official guide for PEM nuts but it was focused on air ducts and concrete. I wanted to see what rocket builders do.