nute

Well-Known Member

- Joined

- Jun 30, 2013

- Messages

- 2,298

- Reaction score

- 5

Hello all,

This is where I'll be documenting the build and flight progress for my winter project, a 2 stage, quasi-semi scale-iiish Black Brant IX. HPR 2 stage always seemed like the pinnacle of complexity, so naturally I figured I had to attempt it, "not because [it] is easy, but because [it] is hard". This is a project I've been thinking about for a month or so now, mentally working through problems as I find them. I'm hoping to finish it by the end of winter, and fly it sometime in the spring or early summer. Each stage will have a 38mm motor mount.

General Parts:

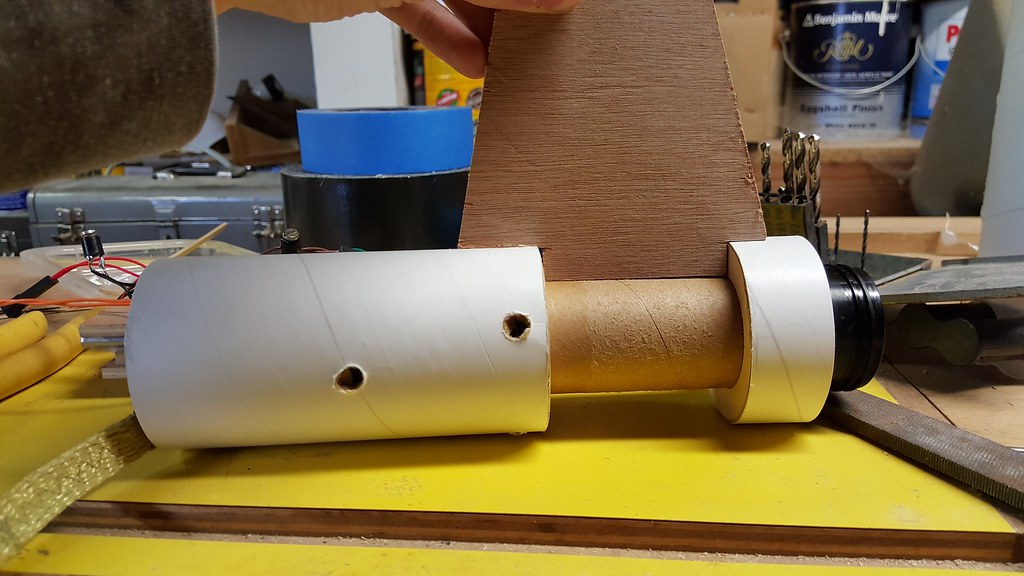

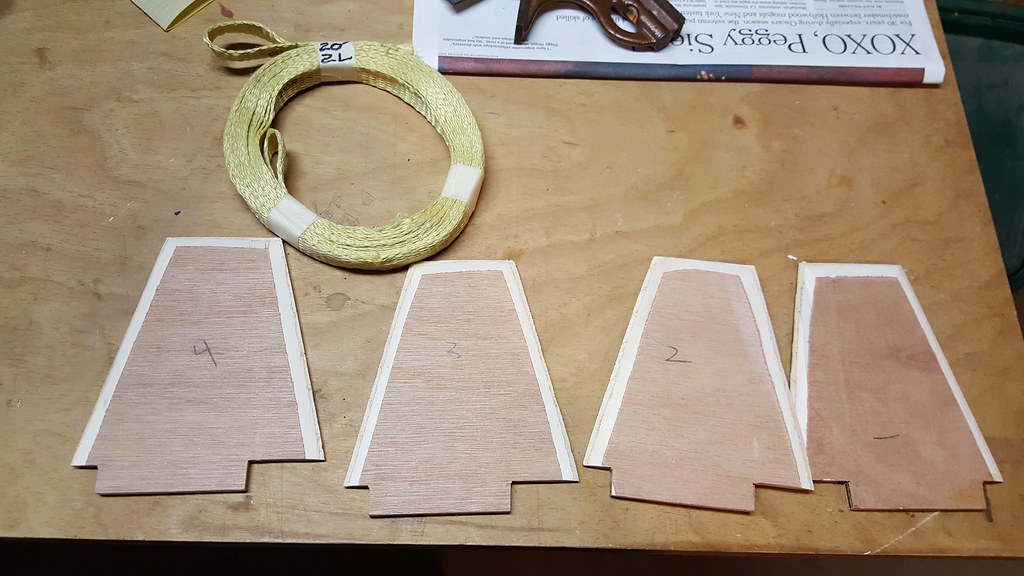

I decided on 2.6" LOC tubing as the happy medium between large (easy to fit stuff) and light (easy to lift). It'll be all scratch, and technically not really scale, but rather a rough approximation of fin shape and general dimensions. I'll be using 3/16 or maybe 1/4" ply for fins, LOC centering rings, motor mounts, couplers, and stiffies, and bulkplates from Madcow. I'm not 100% sure they'll fit perfectly, but their tubing dimensions are within a couple 1000ths of an inch of each other, so I'll take my chances. I'm using the 2.6" ARCAS fiberglass nosecone from Madcow. I like the longer shape much better. I'm not crazy about the additional weight. but I can deal with it. I'll have a tracker bay in the nosecone. The fin slots will be custom from LOC precision, and the fins themselves will be cut here at home, probably with a table saw.

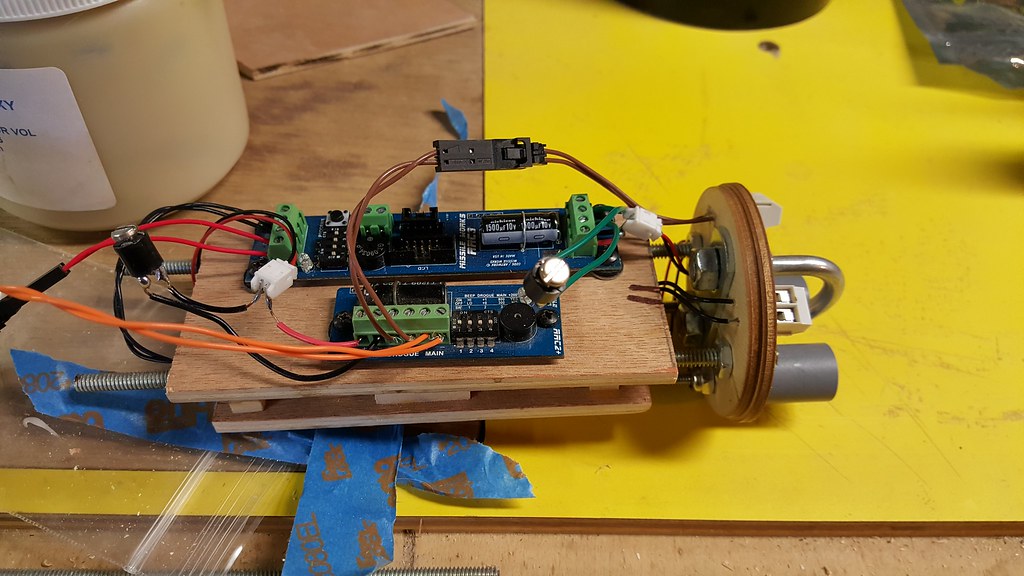

Electronics:

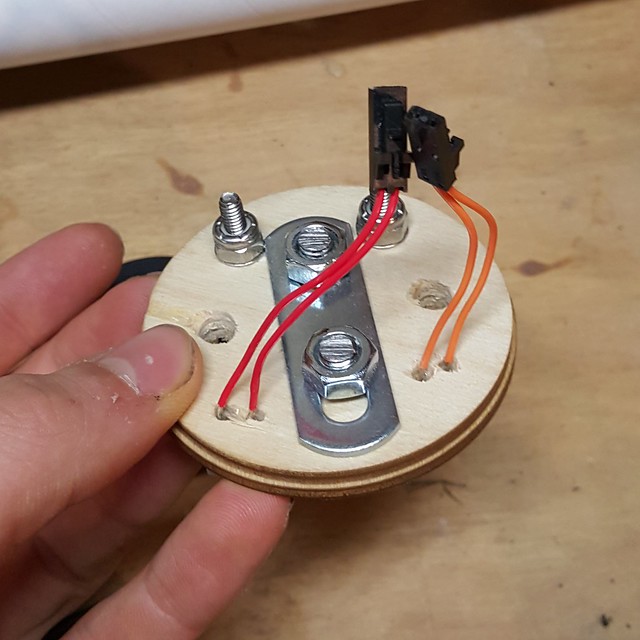

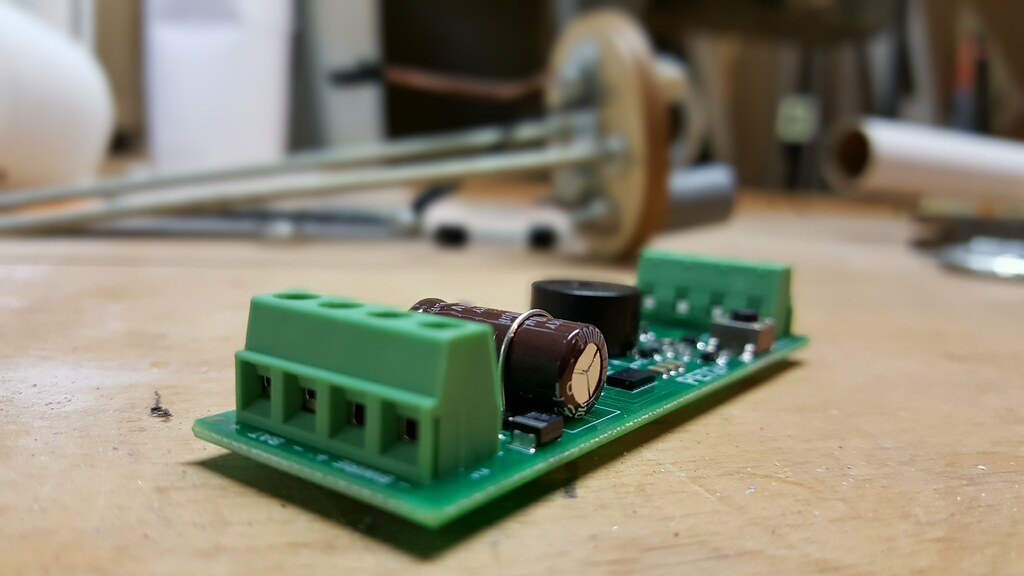

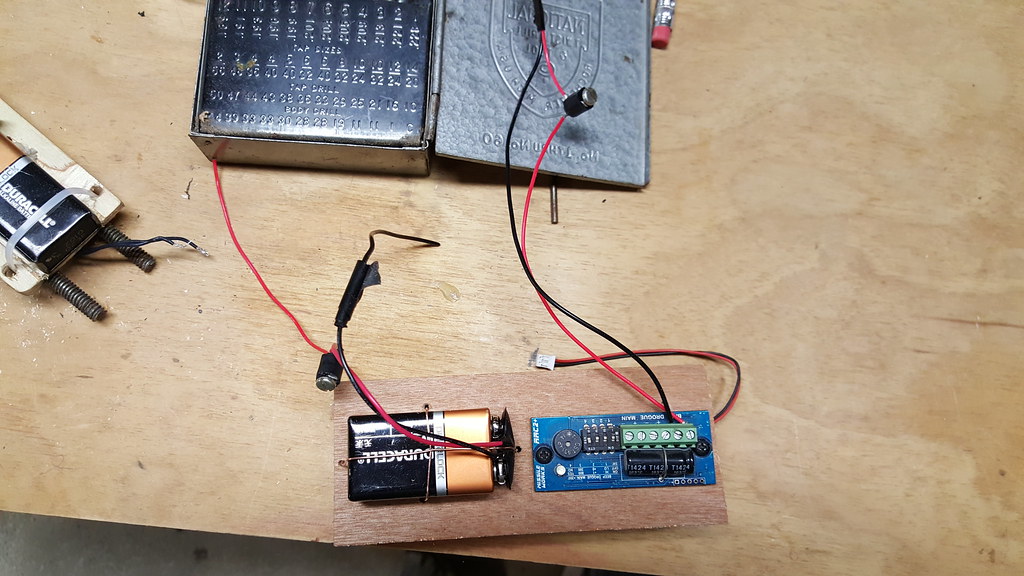

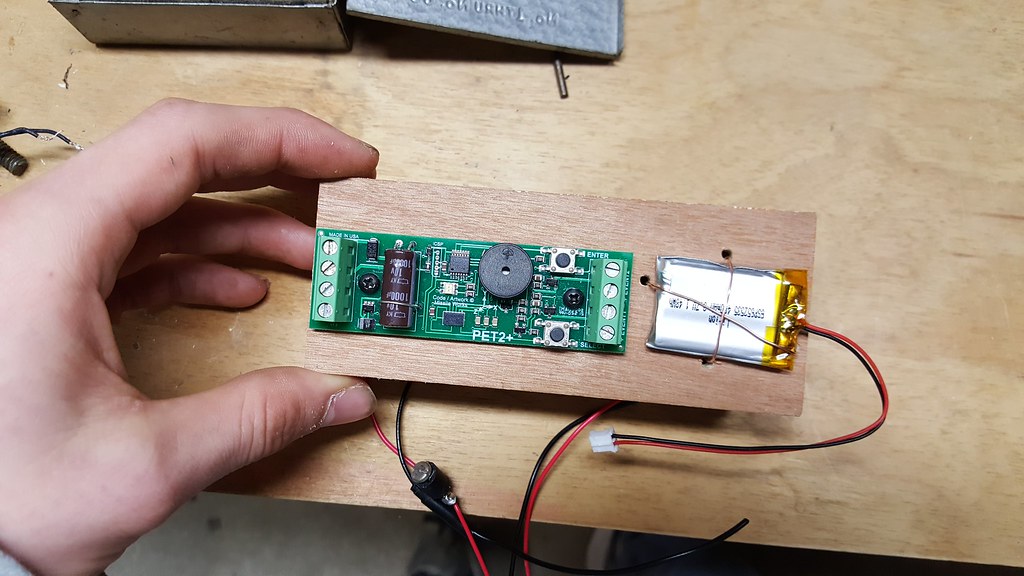

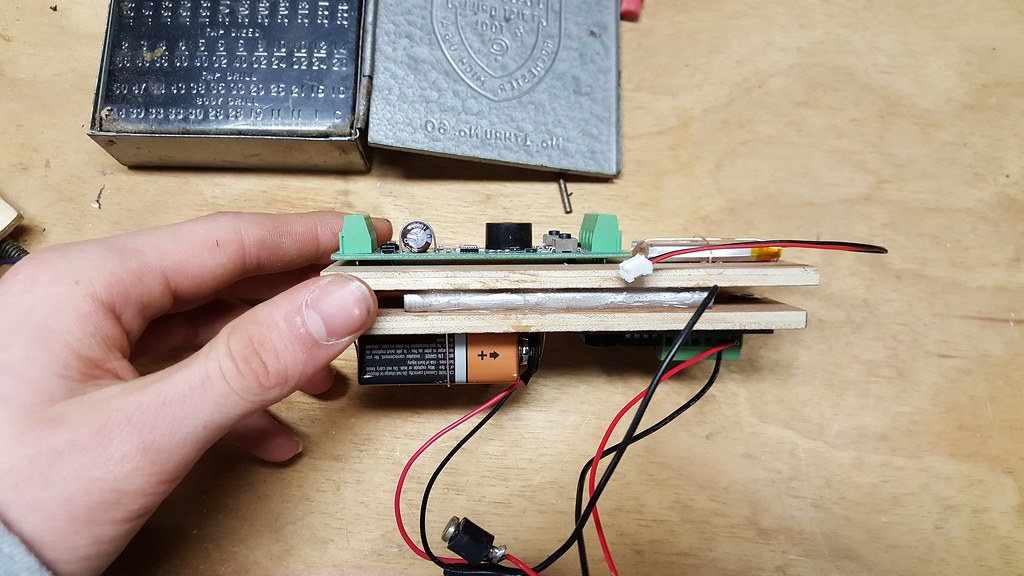

Alright, so the tricky part with two stage is, naturally, the staging. Safety is my primary concern/goal. So the plan is to have an RRC3 in the sustainer taking care of deployment and upper stage ignition, as well as an RRC2+ for backup deployment. The RRC3 will have an altitude-time check for stage ignition, the specifics of which will be determined after final weights are in and the motors have been chosen. There'll be a BRB 70cm RDF tracker in the nosecone.

In the booster's interstage I'll have an RRC2+ for deployment, and a Missileworks PET2+ timer firing a separation charge based on a G check. I'll also have a BRB 70cm RDF tracker on the shock cord. Currently, I'm planning single deploy in the booster, but leave room to add a cable cutter for higher flights. I'm thinking I'll use these screw switches from Aerocon. The plan is to mount them semi-flush to the airframe, so I don't have to negotiate two or three switches through vent holes. I'm now thinking I'll also have a switch between the sustainer igniter and the altimeter, so I can power up the altimeter, verify proper function, and only then energize the ignition channel.

Here's a picture of the current plan and an OR file:

View attachment Two stage build.ork

Since I'm not sure 6" will be enough to easily fit 2 altimeters, batteries, and three switches, I'm thinking, in lieu of custom couplers, I'll just splice two together with a stiffy. I think I'll do the same for the interstage coupler, so I can have a bit more length and make the whole shebang a bit stiffer.

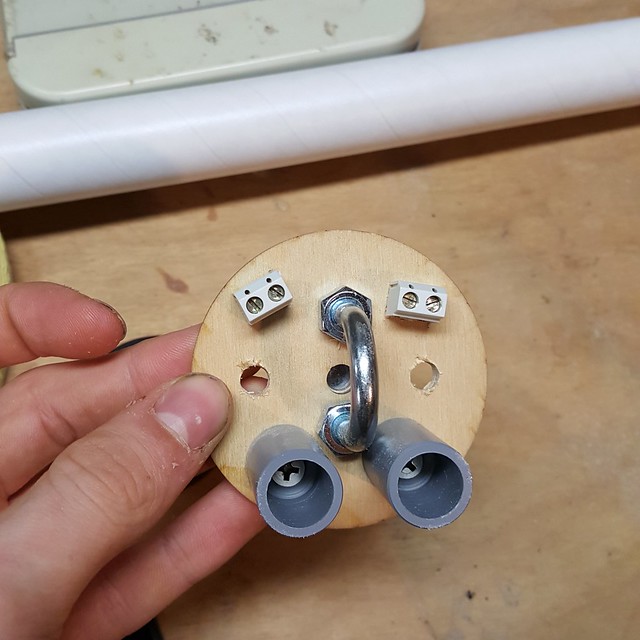

Interstage:

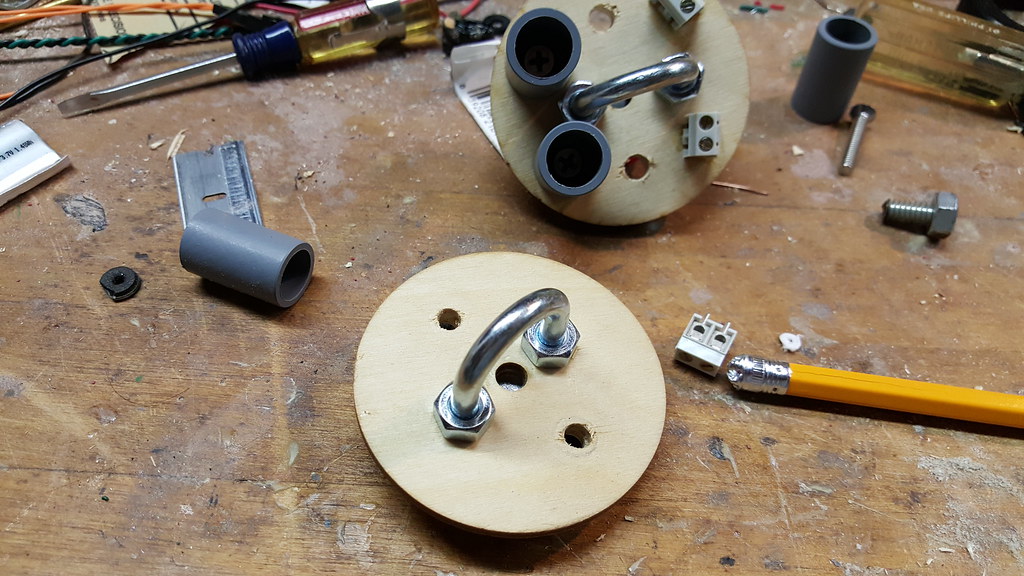

I did a lot of thinking about the interstage and came up with an idea I think will work. It's a bit hard to describe, but this is the idea:

the upper three inches or so will mesh into the upper stage, and have the upper stage motor mount pretty much sitting inside it. a bit below that, there will be a short (1/2"?) section of stiffy that will be glued in place. This will act as a stop for the coupler bulkhead that will slide into the coupler and rest on the stiffy. The other side of the bay will be normal.

So I think that's most of it. I've got a couple H550s, an I600, and an I500T on the docket for Wildman's sale tomorrow. All of those should make good boosters. I'm thinking the first flight will be all up, minus an upper stage motor, so I can see how straight it flies, how it separates, and compare data to OR sims, etc. I'm sure I've forgot some details I'll add later.

This is where I'll be documenting the build and flight progress for my winter project, a 2 stage, quasi-semi scale-iiish Black Brant IX. HPR 2 stage always seemed like the pinnacle of complexity, so naturally I figured I had to attempt it, "not because [it] is easy, but because [it] is hard". This is a project I've been thinking about for a month or so now, mentally working through problems as I find them. I'm hoping to finish it by the end of winter, and fly it sometime in the spring or early summer. Each stage will have a 38mm motor mount.

General Parts:

I decided on 2.6" LOC tubing as the happy medium between large (easy to fit stuff) and light (easy to lift). It'll be all scratch, and technically not really scale, but rather a rough approximation of fin shape and general dimensions. I'll be using 3/16 or maybe 1/4" ply for fins, LOC centering rings, motor mounts, couplers, and stiffies, and bulkplates from Madcow. I'm not 100% sure they'll fit perfectly, but their tubing dimensions are within a couple 1000ths of an inch of each other, so I'll take my chances. I'm using the 2.6" ARCAS fiberglass nosecone from Madcow. I like the longer shape much better. I'm not crazy about the additional weight. but I can deal with it. I'll have a tracker bay in the nosecone. The fin slots will be custom from LOC precision, and the fins themselves will be cut here at home, probably with a table saw.

Electronics:

Alright, so the tricky part with two stage is, naturally, the staging. Safety is my primary concern/goal. So the plan is to have an RRC3 in the sustainer taking care of deployment and upper stage ignition, as well as an RRC2+ for backup deployment. The RRC3 will have an altitude-time check for stage ignition, the specifics of which will be determined after final weights are in and the motors have been chosen. There'll be a BRB 70cm RDF tracker in the nosecone.

In the booster's interstage I'll have an RRC2+ for deployment, and a Missileworks PET2+ timer firing a separation charge based on a G check. I'll also have a BRB 70cm RDF tracker on the shock cord. Currently, I'm planning single deploy in the booster, but leave room to add a cable cutter for higher flights. I'm thinking I'll use these screw switches from Aerocon. The plan is to mount them semi-flush to the airframe, so I don't have to negotiate two or three switches through vent holes. I'm now thinking I'll also have a switch between the sustainer igniter and the altimeter, so I can power up the altimeter, verify proper function, and only then energize the ignition channel.

Here's a picture of the current plan and an OR file:

View attachment Two stage build.ork

Since I'm not sure 6" will be enough to easily fit 2 altimeters, batteries, and three switches, I'm thinking, in lieu of custom couplers, I'll just splice two together with a stiffy. I think I'll do the same for the interstage coupler, so I can have a bit more length and make the whole shebang a bit stiffer.

Interstage:

I did a lot of thinking about the interstage and came up with an idea I think will work. It's a bit hard to describe, but this is the idea:

the upper three inches or so will mesh into the upper stage, and have the upper stage motor mount pretty much sitting inside it. a bit below that, there will be a short (1/2"?) section of stiffy that will be glued in place. This will act as a stop for the coupler bulkhead that will slide into the coupler and rest on the stiffy. The other side of the bay will be normal.

So I think that's most of it. I've got a couple H550s, an I600, and an I500T on the docket for Wildman's sale tomorrow. All of those should make good boosters. I'm thinking the first flight will be all up, minus an upper stage motor, so I can see how straight it flies, how it separates, and compare data to OR sims, etc. I'm sure I've forgot some details I'll add later.