I did just go through the very same exercise, trying to determine which set up was going to be right for me. Here is what I did...

- Needed a system that I could run indoors since I will be doing most of my vacuum in the winter and without a winterized garage in Minnesota you would not get far doing any kind of epoxy work out there.

- I needed a quiet system that was oil free since I was going to do this in my house.

- I wanted to get a bag pressure over 20 inches of mercury.

- and I wanted to spend as little $$ as possible

Here is what I did:

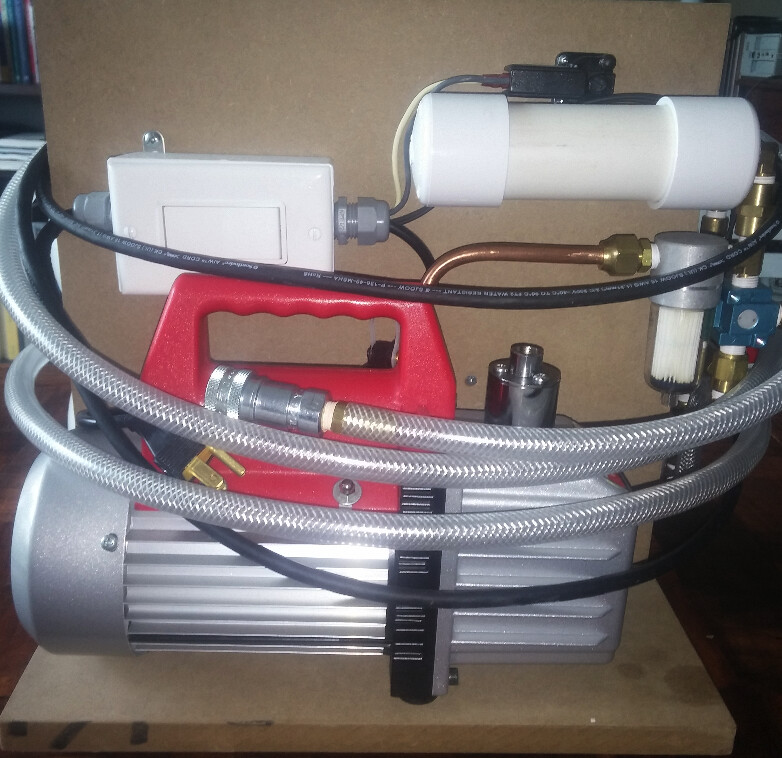

I got a Gast membrane vacuum pump DOA-191-AA 115v 4.2amps

This pump is quiet, no exhaust and I get it to pull 25 inches of mercury. I bought it of eBay for $60 and it runs great. However it was the third Gast pump I bought of eBay, the first two where not pulling near to what I needed them to, the membrane rubber where all dried out.

With this pump I then built a continuous run system with parts from

https://www.veneersupplies.com/products/Project-CRS-Continuous-Run-Pump-Vacuum-Press-Kit.html

This was the cheapest system I could put together that I could run indoors. I have done 2 lay ups to date and I love this thing, especially the bleed function. With that adjustable valve I can start with gentle vacuum getting the bag to position right and then turn up the vacuum.

Hope this helps