EXPjawa

Well-Known Member

I don't typically do build threads much - usually I don't take enough time in the actual building process to take photos, and it seems like few people actually read them, if the number of comments are any indication. Still, I think that this project is worth documenting. A while back, I built a clone of the Estes Astron Cobra, which is, of course, one of their earliest cluster motor models. It introduced me to clustering as well. I decided to do it one better and build an upscaled Cobra - that's what this thread is all about - but it took a while for everything to fall into place.

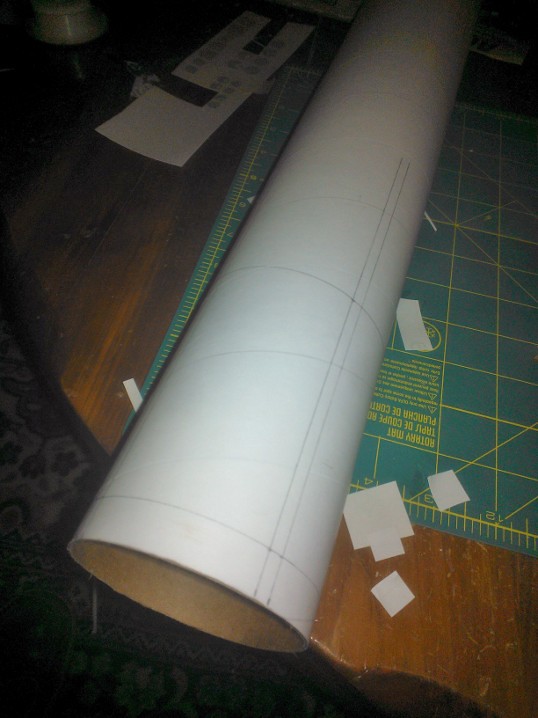

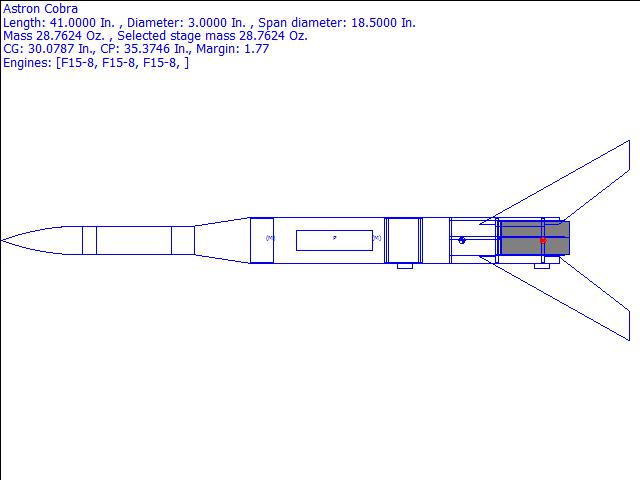

The first step was deciding how big to go. The initial design went to 2.6" main tube and clustered three 24mm mounts. But I did that with an upscale of the Astron Ranger, so was looking to do something different. The second design makes use of thinner wall 3" tube for the lower body, and Aerotech 1.88" tube for the upper. This gives me just enough room to cluster three 29mm mounts, but is light enough to fly on clustered E16 or F15 motors. As such, I consider this to be "midpower", since the combined thrust of three BP isn't really that high. I may go past that at some point, but that's not a current criteria.

Anyway, here's the design, done with Rocksim:

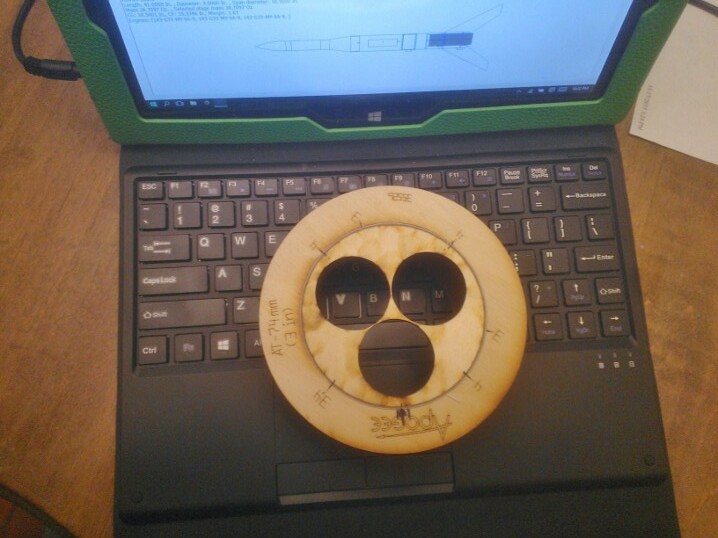

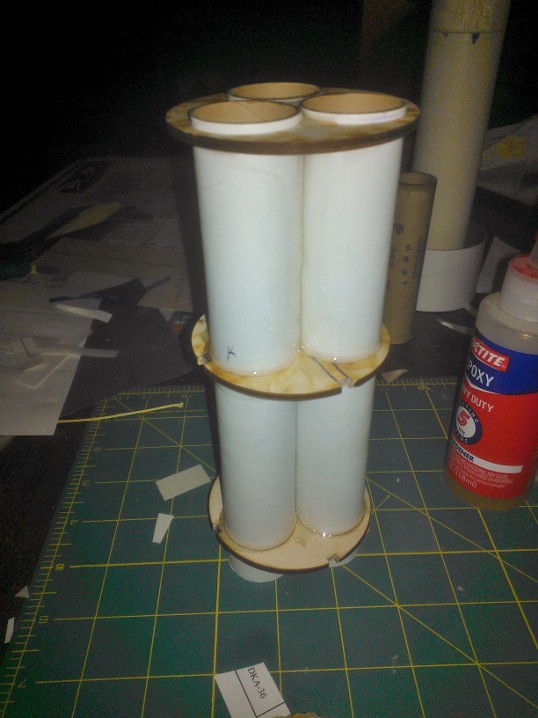

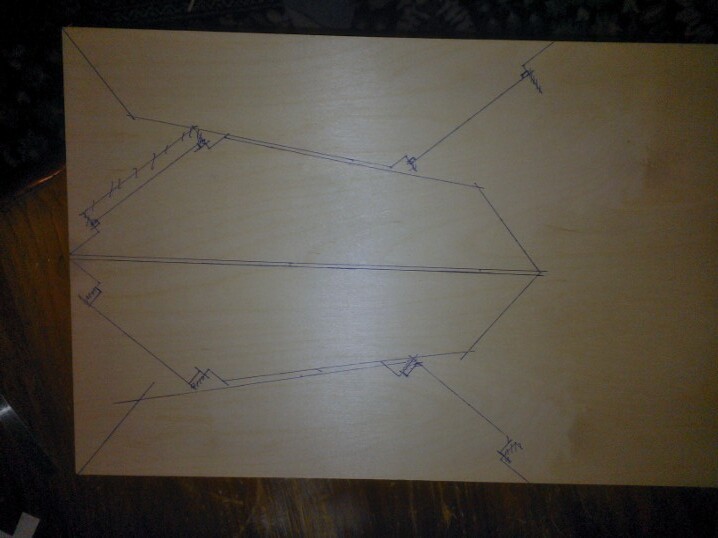

I bought the tubing for this a while ago, but had been sitting on it until a few things fell into place. The first - I needed centering rings for three 29mm tubes inside of Leviathan-sized tube. I could get fairly heavy ply rings for LOC 3", but not for the Estes size. But BMS came to the rescue after a few folks asked them to make rings for PSII tube sizes. I finally got what I needed, and got to point in my build plan where I could do something with them. Here are the bits collected so far:

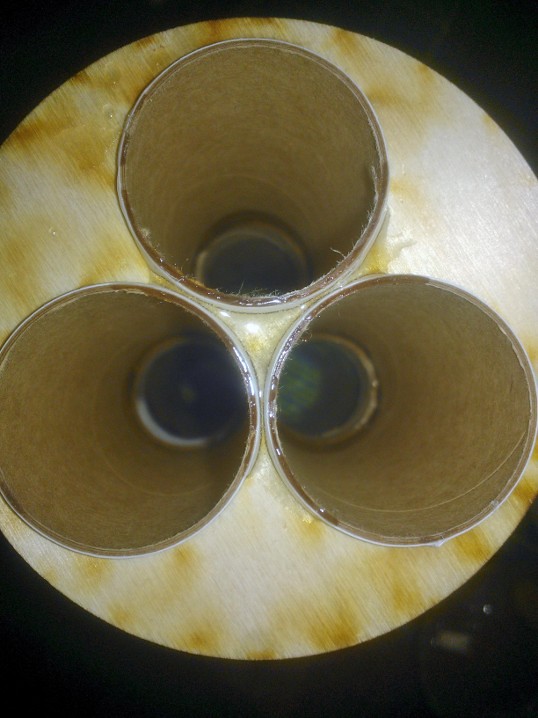

And trimmed to size, to give a better idea of what's what:

Nothing is glued up yet. The coupler and bulkhead pieces are to make an ejection baffle to fit the 3" tube. The next thing to fall into place is the need for upscales of the BNC-50K cone and the transition piece to fit the tubing being used. I contacted Sandman earlier in the week for those and should see them in a few days. And so it begins!

The first step was deciding how big to go. The initial design went to 2.6" main tube and clustered three 24mm mounts. But I did that with an upscale of the Astron Ranger, so was looking to do something different. The second design makes use of thinner wall 3" tube for the lower body, and Aerotech 1.88" tube for the upper. This gives me just enough room to cluster three 29mm mounts, but is light enough to fly on clustered E16 or F15 motors. As such, I consider this to be "midpower", since the combined thrust of three BP isn't really that high. I may go past that at some point, but that's not a current criteria.

Anyway, here's the design, done with Rocksim:

I bought the tubing for this a while ago, but had been sitting on it until a few things fell into place. The first - I needed centering rings for three 29mm tubes inside of Leviathan-sized tube. I could get fairly heavy ply rings for LOC 3", but not for the Estes size. But BMS came to the rescue after a few folks asked them to make rings for PSII tube sizes. I finally got what I needed, and got to point in my build plan where I could do something with them. Here are the bits collected so far:

And trimmed to size, to give a better idea of what's what:

Nothing is glued up yet. The coupler and bulkhead pieces are to make an ejection baffle to fit the 3" tube. The next thing to fall into place is the need for upscales of the BNC-50K cone and the transition piece to fit the tubing being used. I contacted Sandman earlier in the week for those and should see them in a few days. And so it begins!