vcp

Well-Known Member

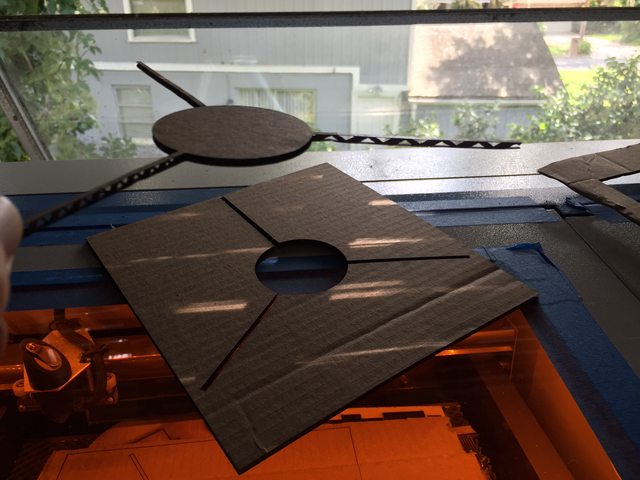

... on the floor. Haven't figured out where to put it yet. It's one of the cheapest cheezy chinese (C3?) laser cutters - 3020 style; 8"x12" cutting area. Bigger cabinet than I thought it would be. I expect it to be the starting point for a lot of modifications and eventual morfitication into a larger, more capable cutter. I suppose it must go in the garage, but I wasn't thinking about the cold - can't freeze the water cooling. Must investigate use of anti-freeze. Sub-problem is that there are no windows in the garage - might have to cut a vent hole in the side door. Got it off ebay and they shipped fast - ordered Friday, arrived Tuesday. No apparent damage but we'll see at first light.