Questions about the HDHH Mongoose 54 from RW.

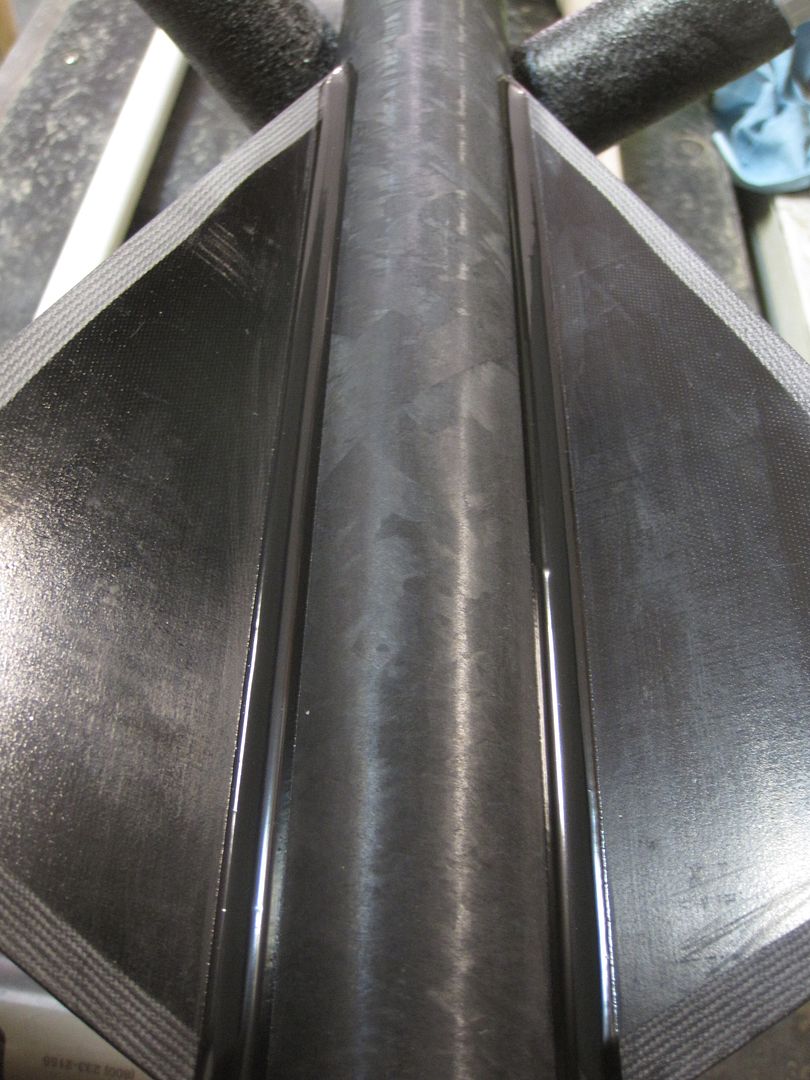

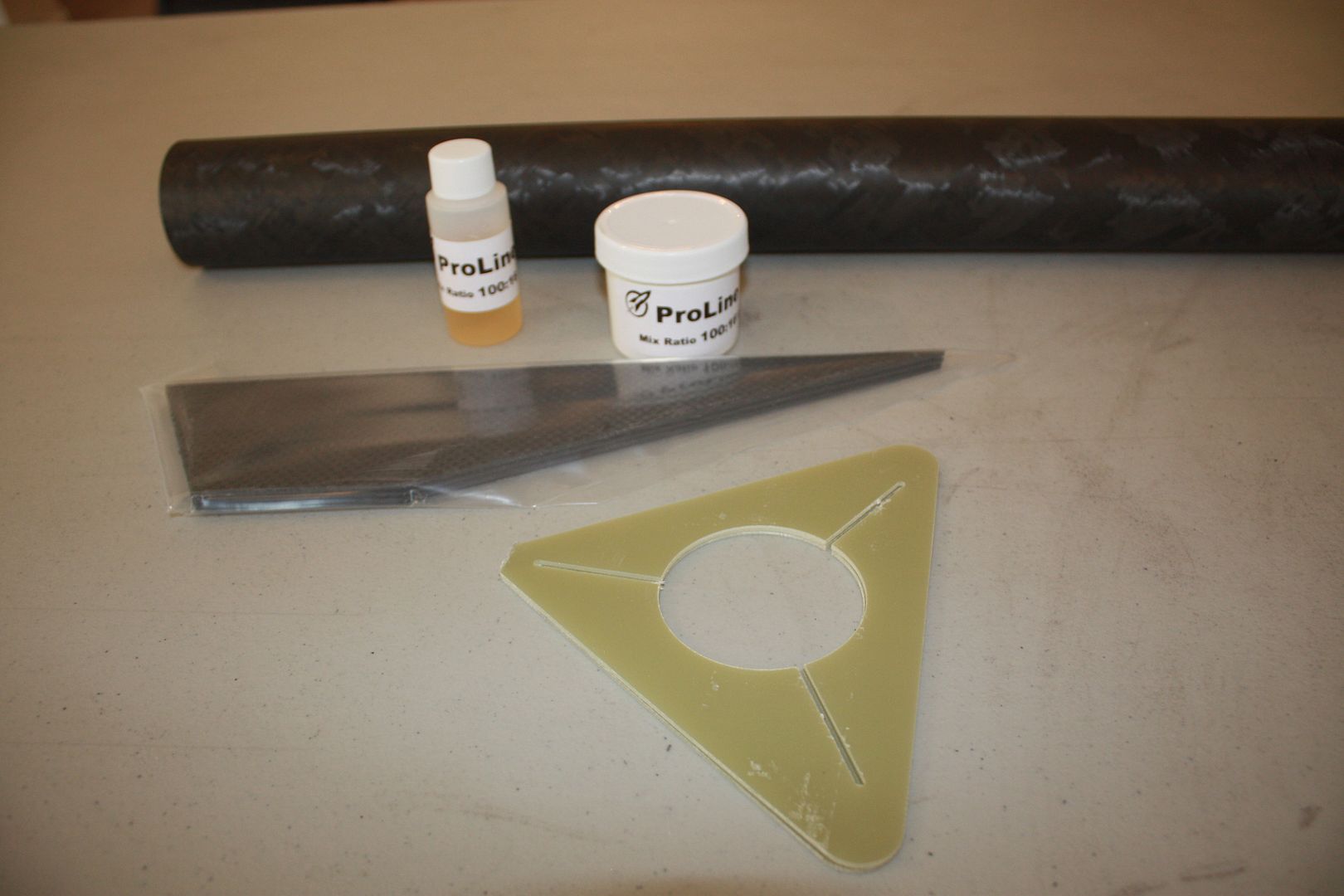

1. What are folks going to do for a lamination treatment of the fincan for aggressive

motor use.

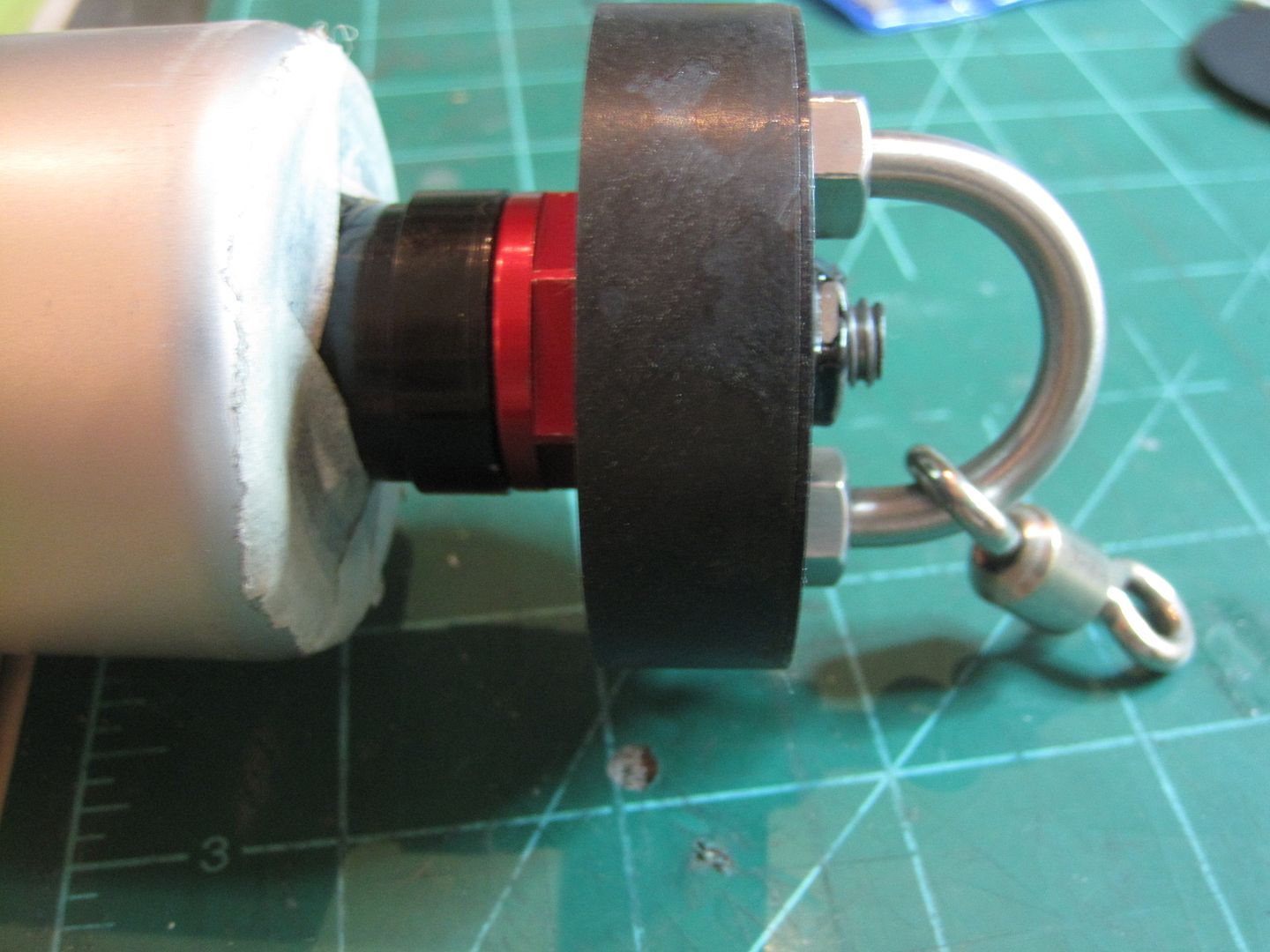

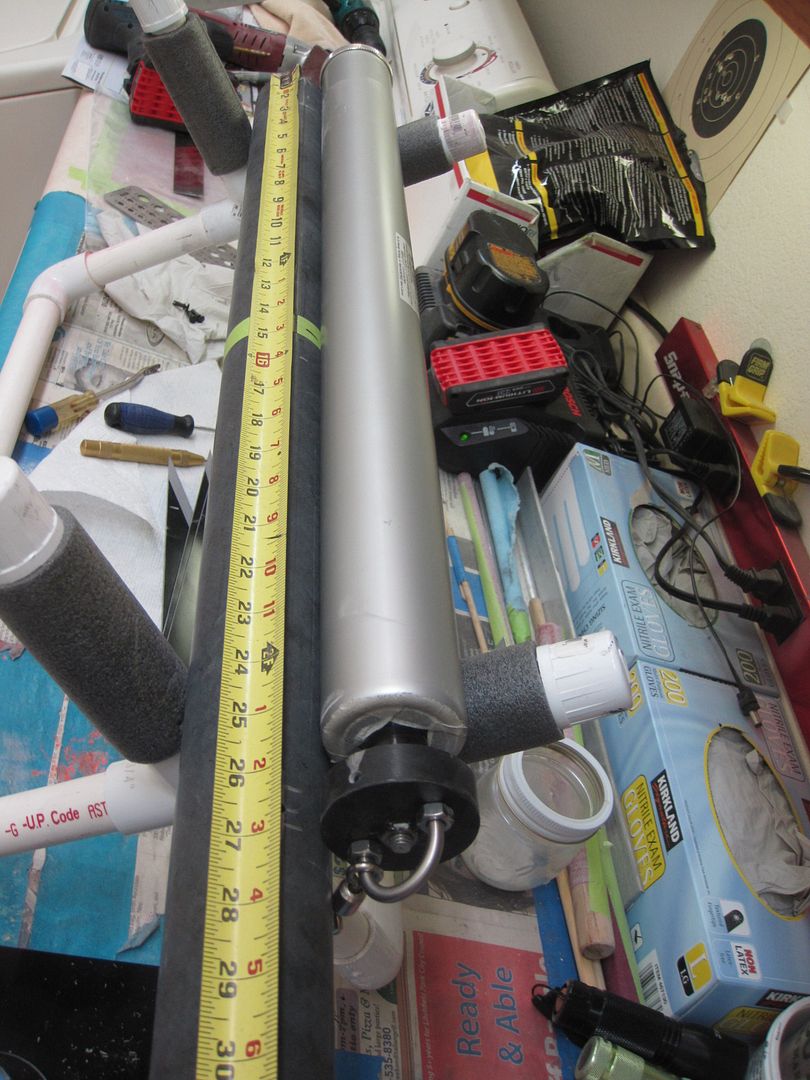

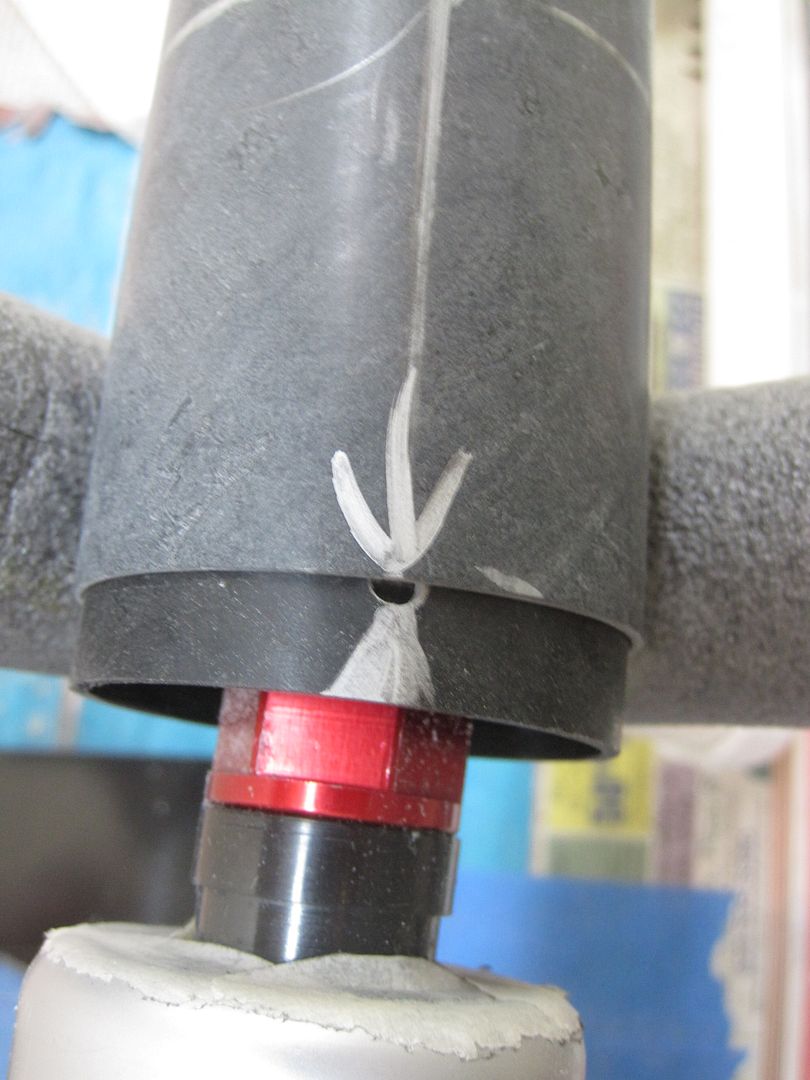

2. I can determine all the parts except the two 3/4" wide coupler rings. Something to

do with motor retention or shockcord installation?

I've done glass lamination but I'd if used, I'd like something to match the rocket

to avoid painting.

Kurt Savegnago

1. What are folks going to do for a lamination treatment of the fincan for aggressive

motor use.

2. I can determine all the parts except the two 3/4" wide coupler rings. Something to

do with motor retention or shockcord installation?

I've done glass lamination but I'd if used, I'd like something to match the rocket

to avoid painting.

Kurt Savegnago