The_Plummeteer

Member

- Joined

- Aug 9, 2015

- Messages

- 20

- Reaction score

- 0

(First let me say, you experienced guys use way too many abbreviations. It took me awhile to actually figure out what "CA" is, and that was only thanks to Google.  Anyway....)

Anyway....)

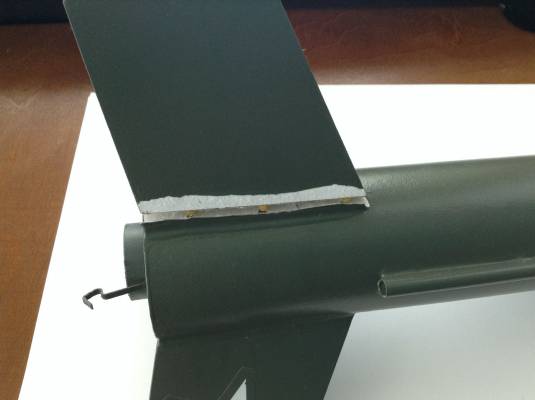

So I'm trying to get a good finish on the balsa wings of my Solar Warrior, and I've been reading a lot of posts here about different ways to accomplish it. The methods I've seen mentioned are papering, sanding sealer, CA and thinned-out wood glue. Papering is a little more than I want to get into at the moment, especially with the compound angle the Solar Warrior fins use. I'm not against CA filling, but I've yet to find a post that explains just how the heck you apply and smooth it without adhering yourself or the tools to the fin within seconds. That leaves the wood glue and the sanding sealer.

I'm prepared to try the thinned wood glue, as I have a bottle of Titebond II and some brushes. But the sanding sealer sounds like a more sure-fire method.

I went looking for some sanding sealer, but all I could come up with is wood filler paste. Is this the same thing? It seems awfully gritty/chalky, and dries as a try to smooth it in (on some scrap balsa). Am I supposed to thin this as well?

Thanks for any tips/feedback you can offer! I don't wanna screw this up.

So I'm trying to get a good finish on the balsa wings of my Solar Warrior, and I've been reading a lot of posts here about different ways to accomplish it. The methods I've seen mentioned are papering, sanding sealer, CA and thinned-out wood glue. Papering is a little more than I want to get into at the moment, especially with the compound angle the Solar Warrior fins use. I'm not against CA filling, but I've yet to find a post that explains just how the heck you apply and smooth it without adhering yourself or the tools to the fin within seconds. That leaves the wood glue and the sanding sealer.

I'm prepared to try the thinned wood glue, as I have a bottle of Titebond II and some brushes. But the sanding sealer sounds like a more sure-fire method.

I went looking for some sanding sealer, but all I could come up with is wood filler paste. Is this the same thing? It seems awfully gritty/chalky, and dries as a try to smooth it in (on some scrap balsa). Am I supposed to thin this as well?

Thanks for any tips/feedback you can offer! I don't wanna screw this up.

I'm amazed how quickly people respond to posts here. Shouldn't you guys be busy building rockets or something? Ha!

I'm amazed how quickly people respond to posts here. Shouldn't you guys be busy building rockets or something? Ha!