FishInferno

Member

- Joined

- Mar 26, 2015

- Messages

- 21

- Reaction score

- 0

I didn't really know where to put this, so I put it here because this is a scratch build, sorry if it should be somewhere else!

Anyway, I am in the final stages of building a low-power rocket modeled after the game "Kerbal Space Program". Her it is balancing on its nose:

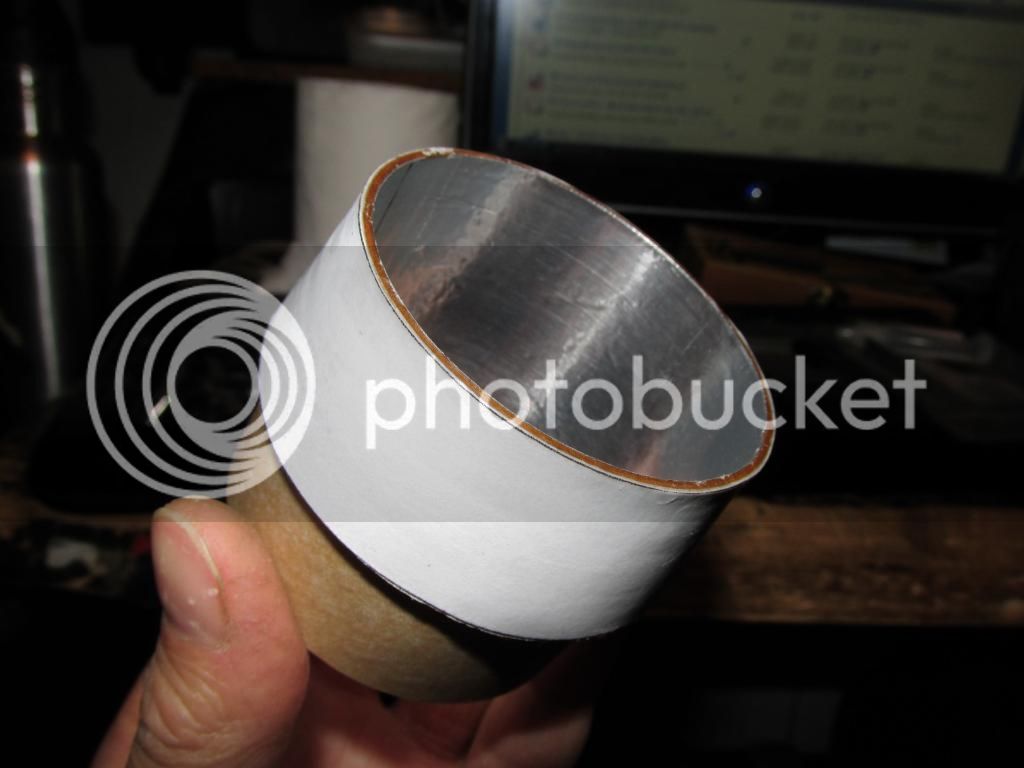

My one question is about the black engine "nozzle". I am worried that it will be torched by the engine exhaust. Here is a closeup of the engine mount inside the nozzle:

Is this too close? I planned on using C engines for it, if that matters.

Anyway, I am in the final stages of building a low-power rocket modeled after the game "Kerbal Space Program". Her it is balancing on its nose:

My one question is about the black engine "nozzle". I am worried that it will be torched by the engine exhaust. Here is a closeup of the engine mount inside the nozzle:

Is this too close? I planned on using C engines for it, if that matters.