BayouRat

Well-Known Member

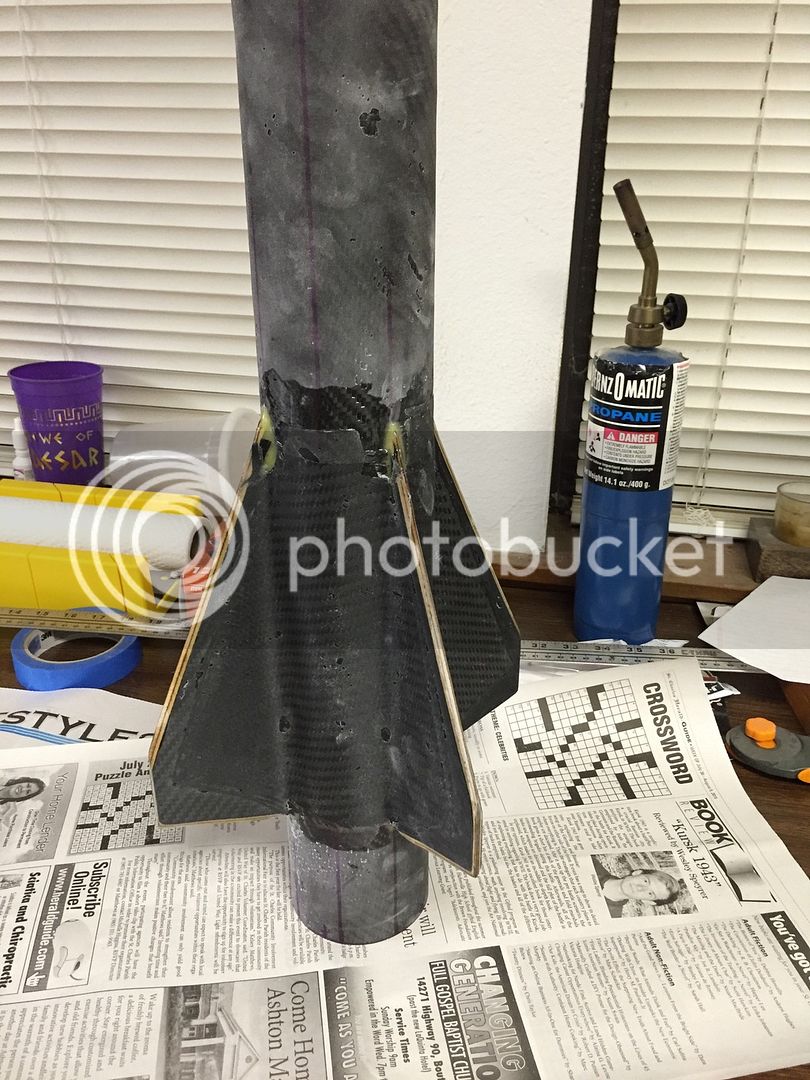

I'm building this for AirFest. It is designed specifically for the 75/6000 research motor I have. Here is some of the specifications and materials.

Airframe is a 48" Carbon Fiber reinforced PML 3" tube (3 layers of 5.7oz 2x2 twill)

Nose Cone is a PR 3" VonKarman

Fins are 3/16" Aircraft Plywood sandwiched between 2 layers of the carbon cloth. Then 2 more layers tip to tip.

Rocket will be dual deployment out the front end with a cable cutter.

Electronics will be a Raven Flight Controller and a Beeline 70cm GPS transmitter.

Airframe is a 48" Carbon Fiber reinforced PML 3" tube (3 layers of 5.7oz 2x2 twill)

Nose Cone is a PR 3" VonKarman

Fins are 3/16" Aircraft Plywood sandwiched between 2 layers of the carbon cloth. Then 2 more layers tip to tip.

Rocket will be dual deployment out the front end with a cable cutter.

Electronics will be a Raven Flight Controller and a Beeline 70cm GPS transmitter.

Last edited: