This rocket probably has not flown in 15+ years... I know the last time I posted about this rocket was 8-years ago, here is the thread:

https://www.rocketryforum.com/showt...r-3-0-Restoration-Project&highlight=excalibur

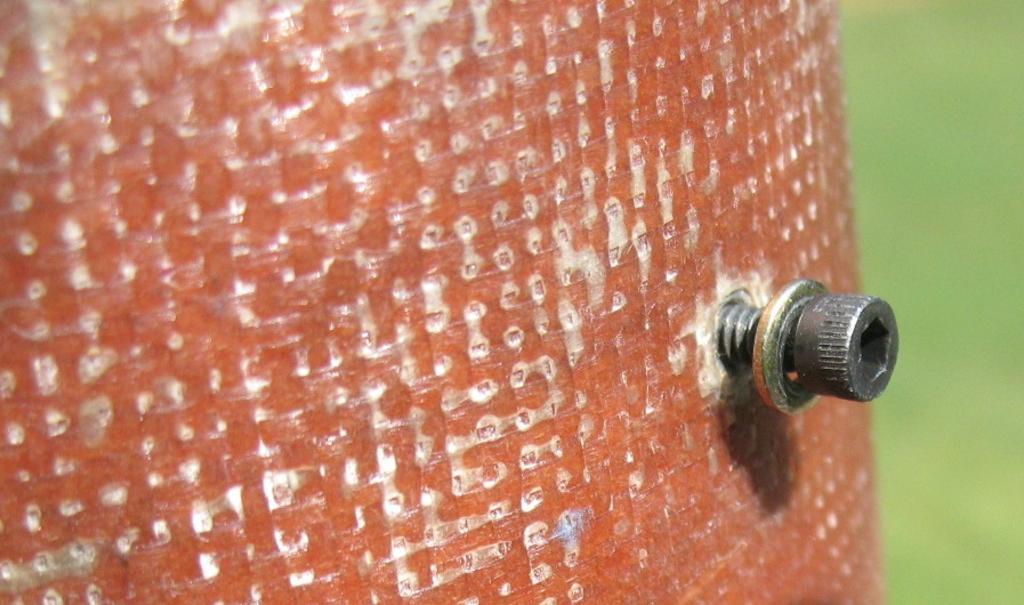

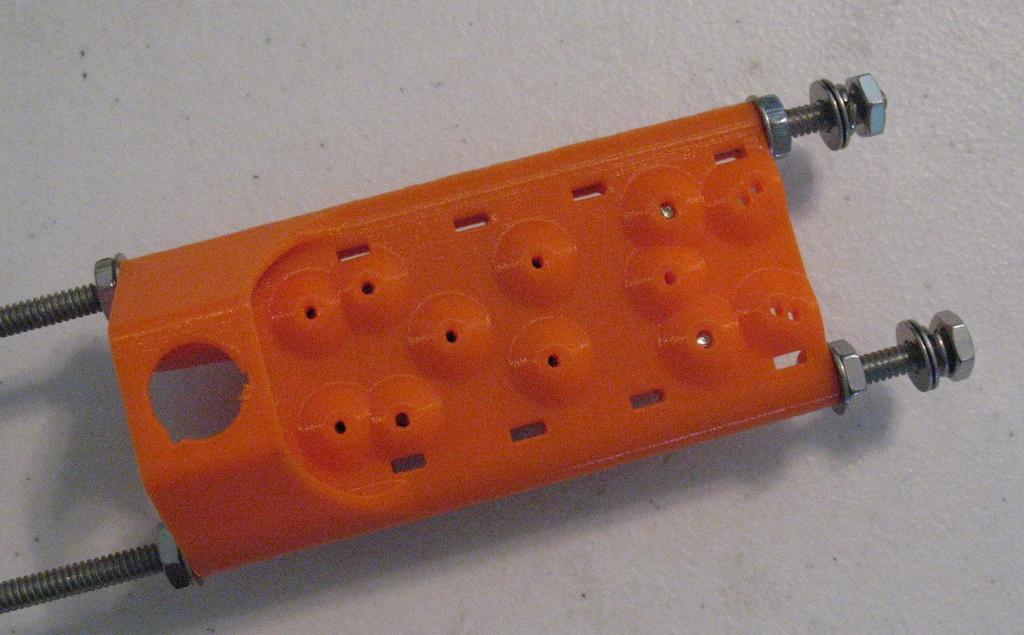

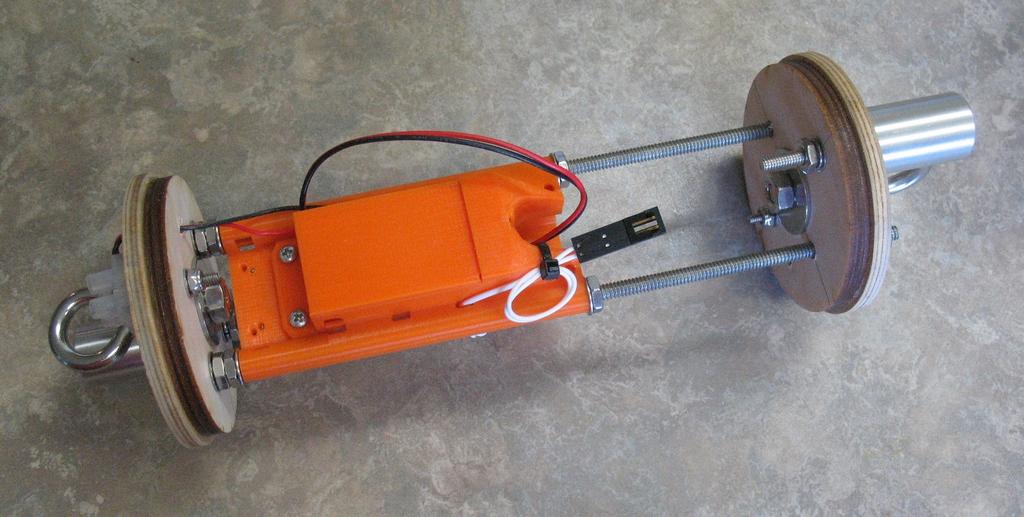

She had 8-years worth of dust on her when I dug her out, otherwise the rocket remains in limbo, until I decided to finish the resurrection. In that linked thread, my old username was Johnnie, which coincidentally is my real name...go figure. I have an action item list made, and will finish the rocket off on this thread. I have ordered a few parts from Apogee Components, and once they arrive, I will be well over the 80% completion mark.

I will post some new updated images as they get uploaded etc.

https://www.rocketryforum.com/showt...r-3-0-Restoration-Project&highlight=excalibur

She had 8-years worth of dust on her when I dug her out, otherwise the rocket remains in limbo, until I decided to finish the resurrection. In that linked thread, my old username was Johnnie, which coincidentally is my real name...go figure. I have an action item list made, and will finish the rocket off on this thread. I have ordered a few parts from Apogee Components, and once they arrive, I will be well over the 80% completion mark.

I will post some new updated images as they get uploaded etc.