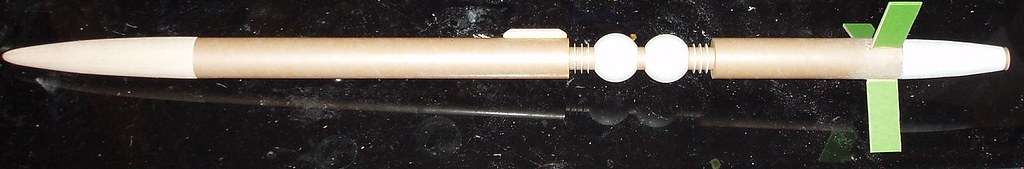

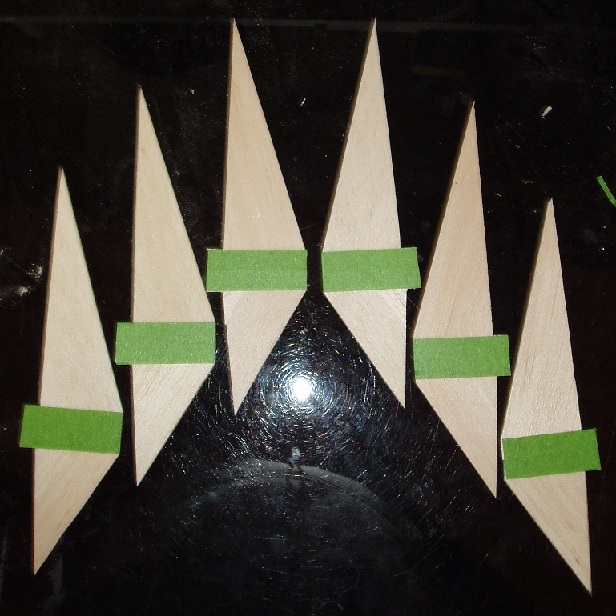

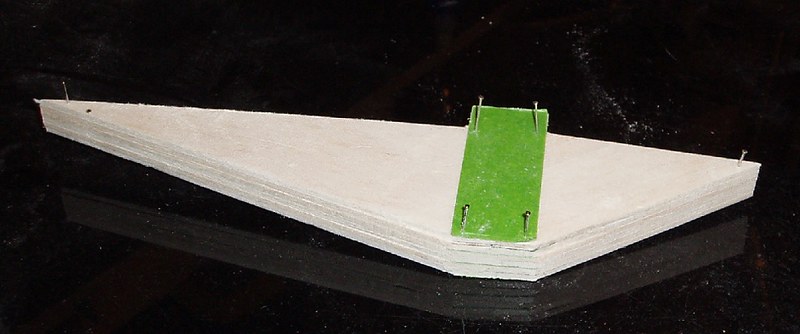

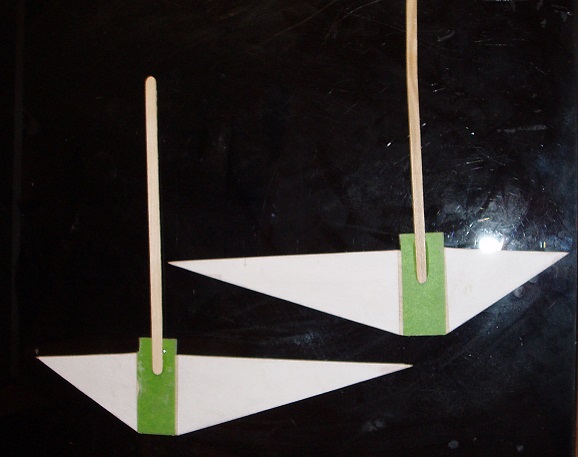

Here is the completed airframe. I have masked the faces and the tips of the fin spars since they will be glue surfaces once all the components are painted. Next was the usual fun and games of sanding, filling, patching and priming. I will spare you any dialogue on that not-so-fun step...

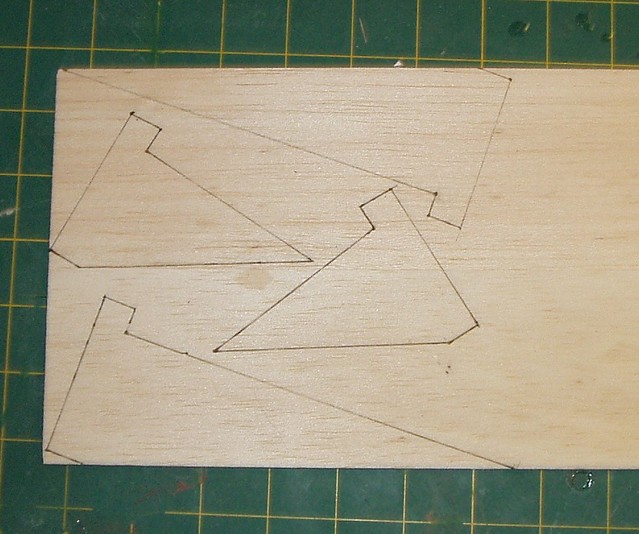

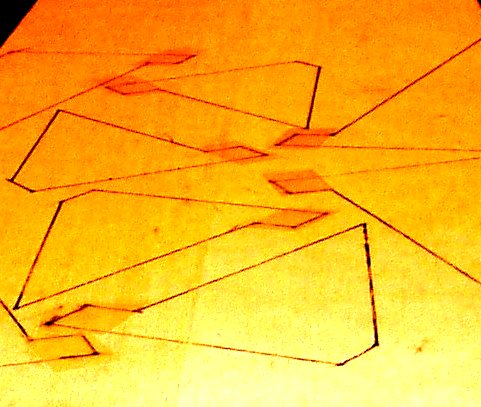

The tail ring was cut from a 6" diameter coffee can (this particular one was from Wallyworld). Using the same technique as was used to cut the shoulder off the boattail, a band of masking tape serves as a cutting guide. The first cut takes off the metal ring at the top of the can. Measuring for a 1.5" wide ring, another masking table band aids in freeing the wring.

The coffee can is made from cardboard. To keep from the edges from swelling and/or fraying, they should be sealed immediately prior to any further handling. Carefully soak both the top and bottom edge of the ring with thin CA/ Since both the interior and exterior of the ring is covered with a plastic coating which will be removed, drips are no concern

The plastic coating peeled off the interior easily. Unfortunately, the exterior coating was uncooperative. It had to be sanded off. Prior to any filling, the interior glue areas need to be marked and masked. Slide the ring over the spars to mark positions. The ring is wider than the spars, therefore, there will be 1/4" of ring above and below each spar. The mark is masked with a narrow strip of tape. Now the interior and exterior of the ring can be filled and sanded.