First of all, let me apologize in advance about the pictures. Either my camera, or the photographer, or a combination of both, are not up to the task of taking close-up shots.

Secondly, I am taking the time to make comments about some of the techniques I used (or discovered) during the build. If you don’t want that level of detail, please let me know and I will omit them going forward.

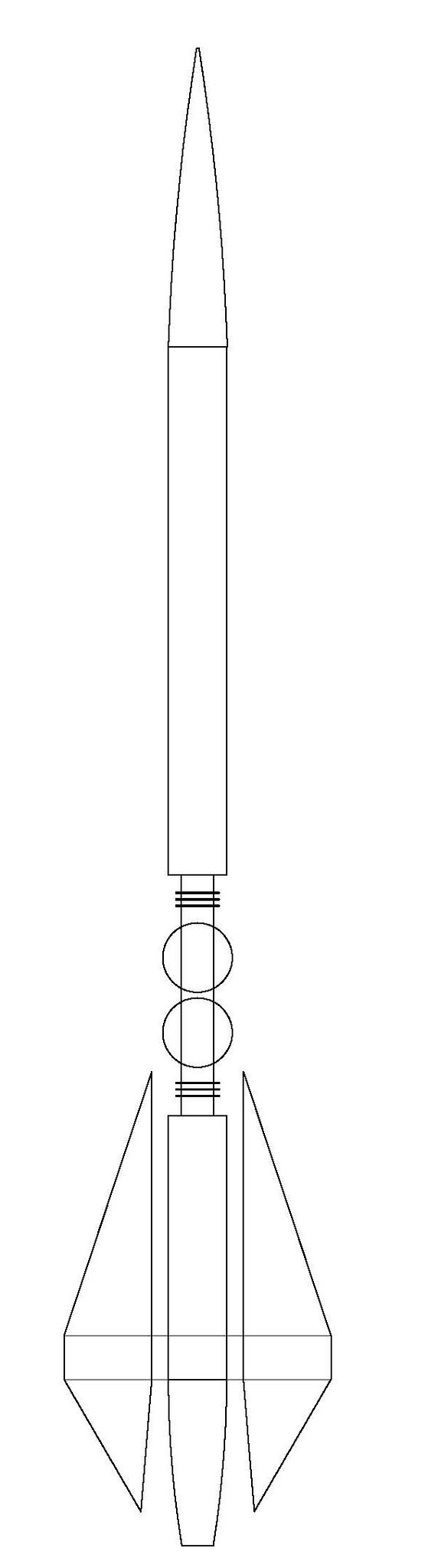

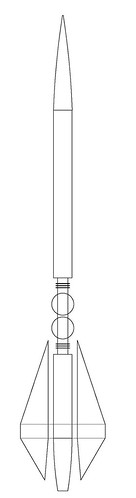

At the outset, I realized I have not determined the length of the central BT-20 tube. That is because it is depended on 2 unknown lengths: the length of the boat tail, and how much space will a ping pong ball take up. So before I do the build in earnest, I need to get those 2 lengths figured out.

A few years ago, I had this “brilliant” idea of using paint stripper to clean up an old Estes Comet kit for repainting. I did not know then what I know now – paint stripper does not play nicely with plastic parts. The stripper fused the old primer into the surface of the plastic, leaving behind a lumpy, rippled surface, and completely destroyed the step-down of the shoulder. But with this build, I have a chance to repurpose this poor excuse of a nose cone into a tail cone. I have done some sanding to work all the ripples out, but there are still a number of pits and dents that I will remediate during finishing steps.

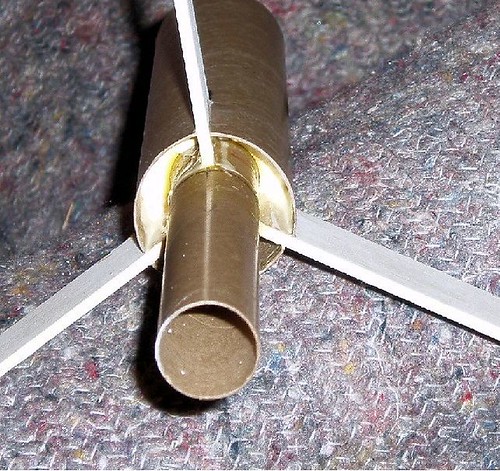

I needed to remove the cone-shaped protrusion from the bottom of the former nose cone in order to allow space for the ring supports which you will see in a later step. By wrapping several layers of masking tape around the shoulder, I had a guide that I could seat the razor saw against, allowing a reasonably straight cut.

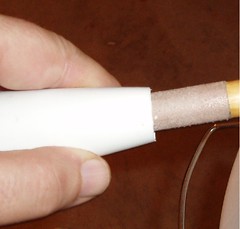

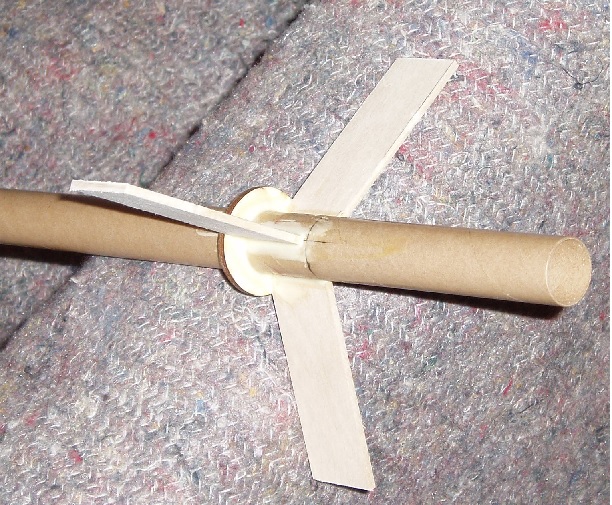

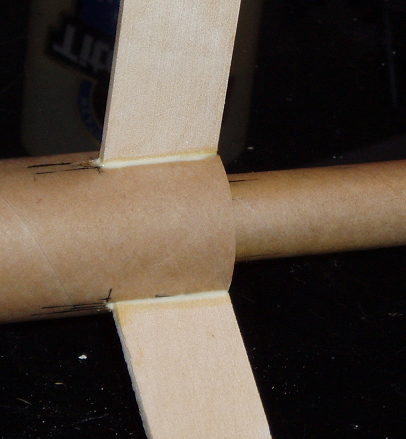

Next, was the step to remove the tip of the former nose cone. I knew the cut didn’t have to be perfect, since it would be sanded to the final size, but starting out with a cut that is very close to being at right angles to the center line decreases the amount of swearing polluting the air in my workshop. Here is my simple technique for marking the cut line. I put a small section of body tube on the shoulder section so that I would have something to hang onto. Then my holding a 2050 centering ring

stationary in one hand, I slowly “screwed” the cone into the ring as if I were screwing in a light bulb. By turning the cone as I pressed it into the ring, it kept it going straight in. After marking a line around the ring I cut off the tip with a razor saw.

At this point, the opening is not large enough to accept a tube, and needed to be sanded to size by alternating between sanding against a flat surface, and thinning the wall from the inside. One unknown length down, one to go…

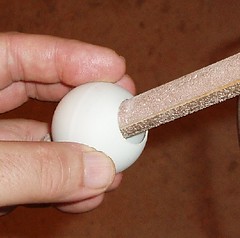

This is the very first time I have ever used a ping pong ball on a rocket. And since Shrox is not here to edumacate me on the definitive technique for cutting holes in them, I was on my own to figure it out. My first step is to mark the circle. By covering the end of a tube with ink, I “stamped” a circle on the ball (The circle came out a bit faint, so I played with the contrast of the picture so it you could see it).

The first thing I learned was that even with a brand new blade, there was no easy way to cut into the curved surface – I could not control the blade well enough. So I came up with the idea of perforating around the circle using a straight pin. Then I could use my knife tip to cut between the holes.

Then using the same sanding rod I used to thin the wall of the boat tail, I sanded the opening until it was the correct size. However, I discovered that pushing in and out of the hole was not going to work with the more fragile ping pong ball material. Instead, I held the sanding rod stationary while I twisted the ball back and forth (think of the motion of turning a door knob back and forth).

Once the first hole is done, by pushing in a tube until it seats firmly against the interior of the ball, it shows the location of the next hole. But how do you mark that? I’d like to credit Gary Byrum for this next technique. By illuminating the ball from the inside, using my handy dandy Sirius Rocketry mini flashlight, I could clearly see the circle I needed to mark. Then I used the same techniques as before to do the second hole.

Final unknown length determined. And this is all I got done last night.