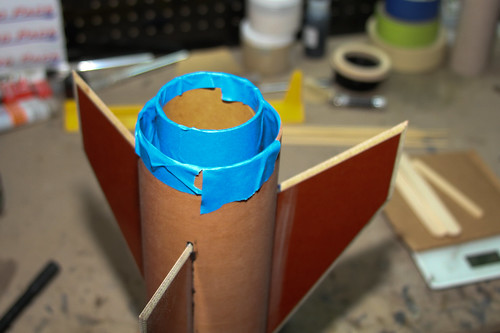

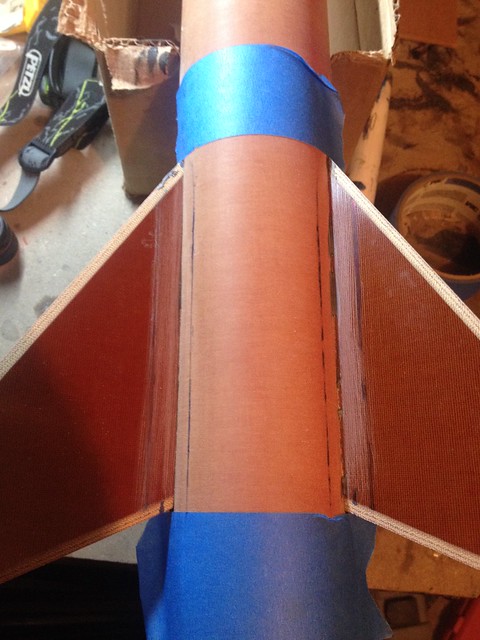

In what seems a broken record by now - WOW. These parts are cut perfectly. No dust to wash off, no sanding to fit parts ...this kit is ready to go. I opted to have the booster extended out to 30"

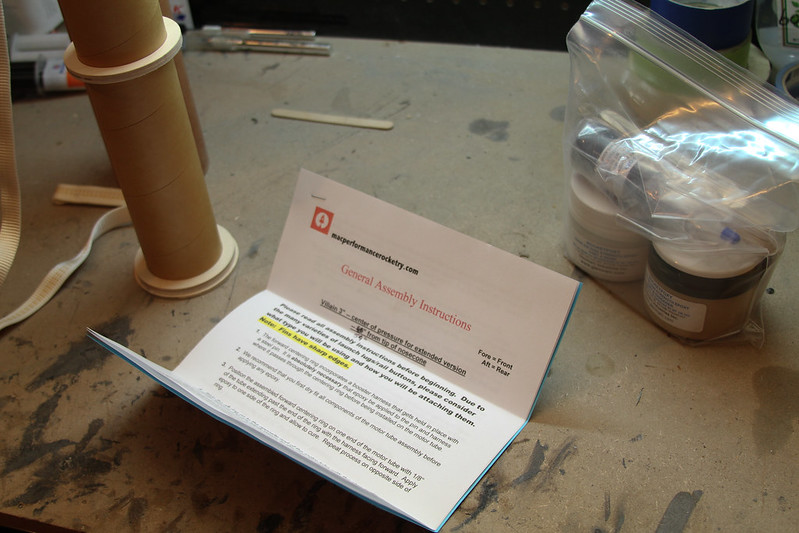

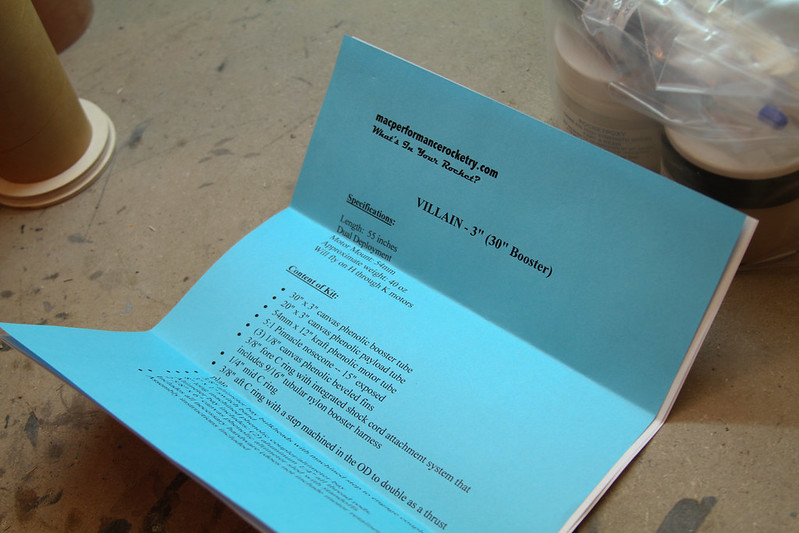

I'm busy with the holiday and LDRS cleanup still, but I wanted to get this open, snap a few pics and check it out. This will be a full build thread. So here we go.

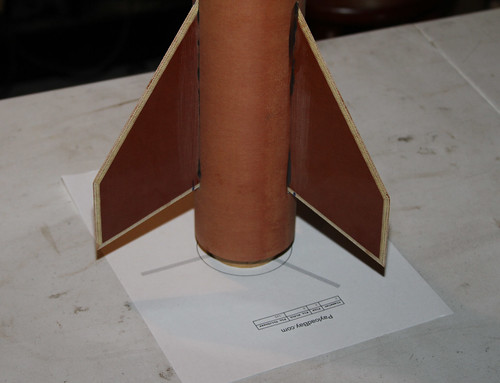

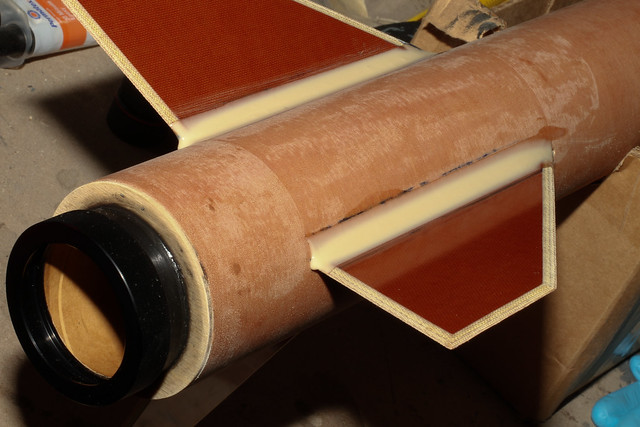

Parts layout, including official LDRS mud on my table.

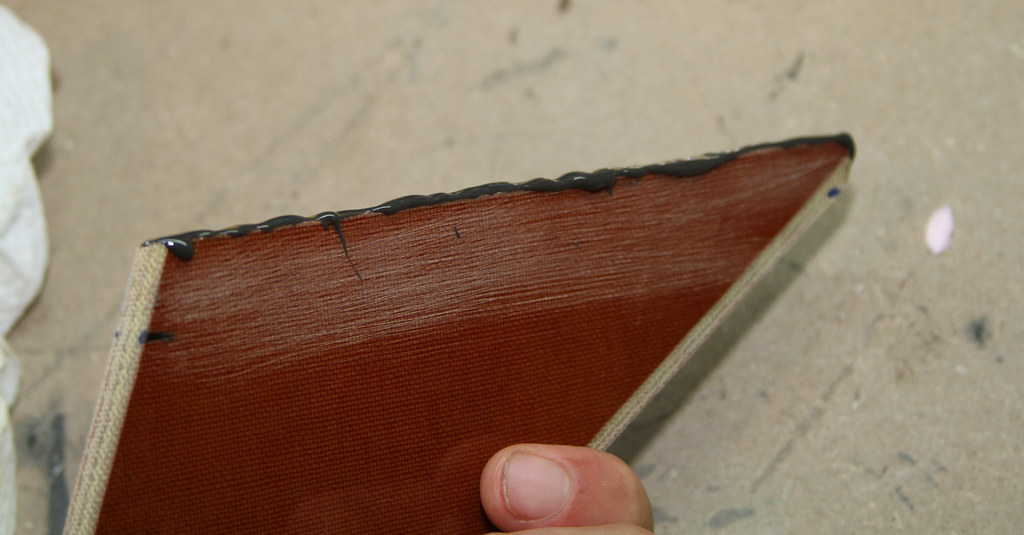

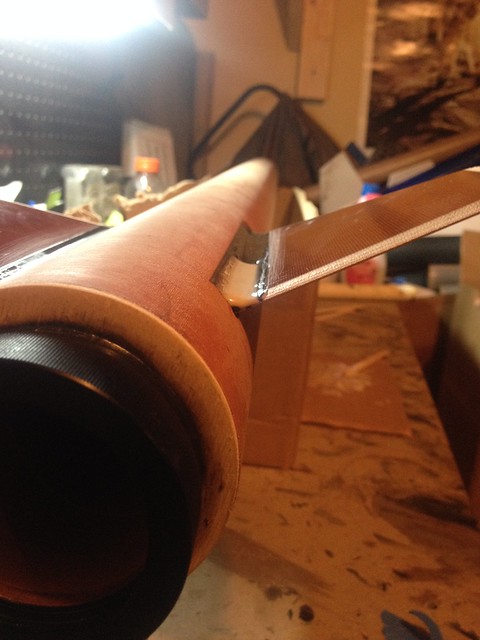

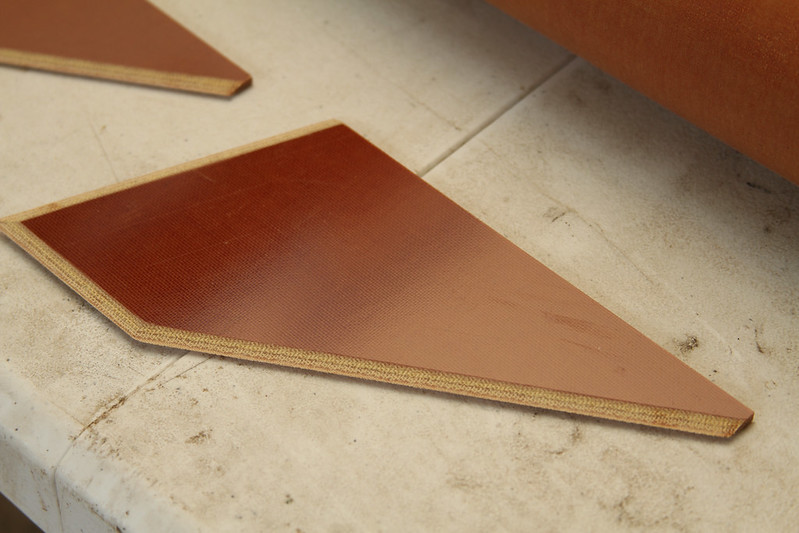

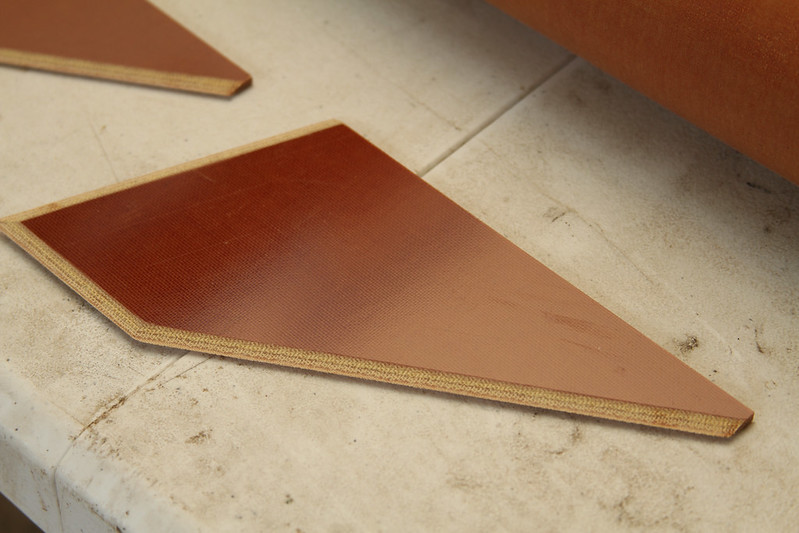

One of the canvas fins. Feels nice.

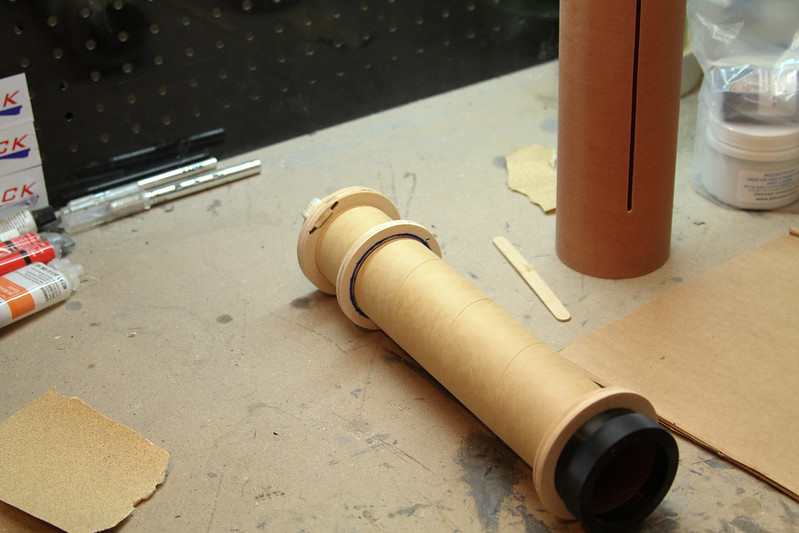

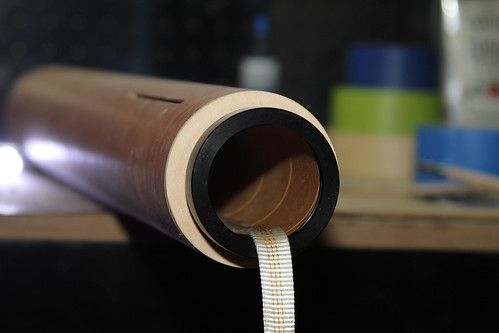

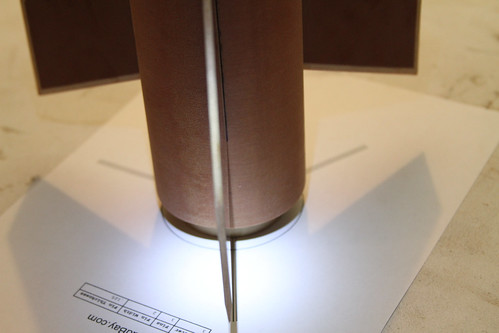

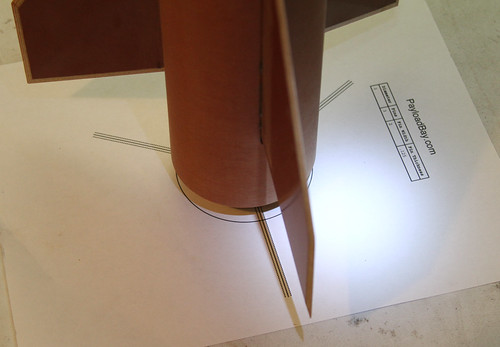

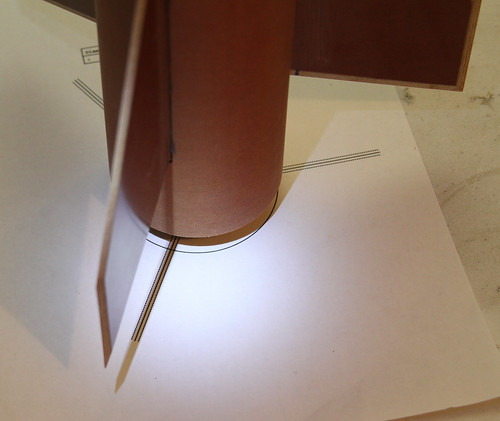

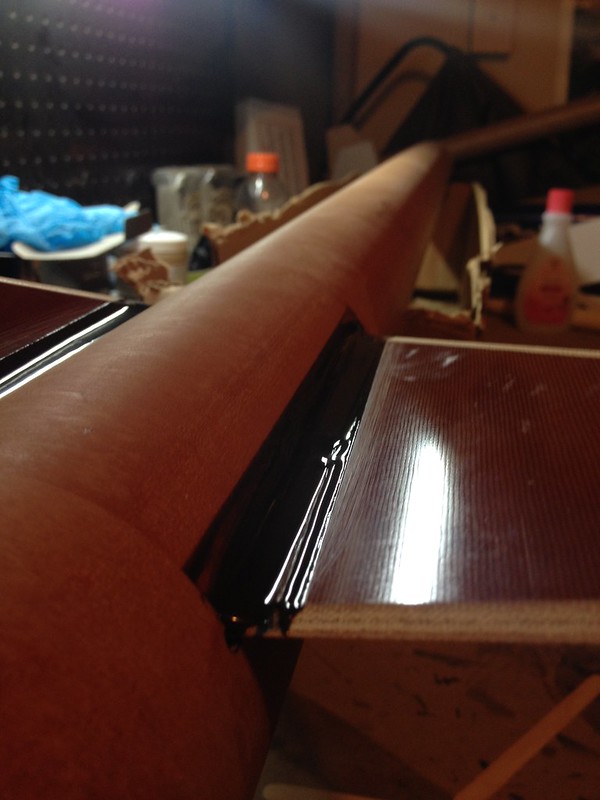

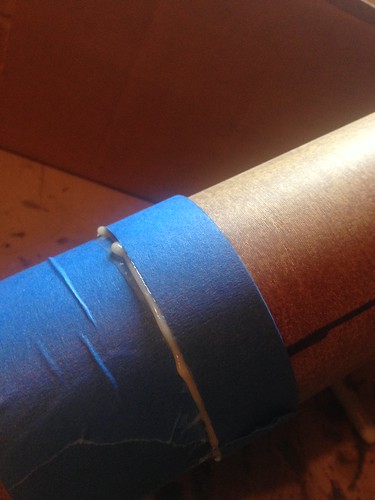

ALL DONE! OK not really...but this snapped together nicely for a dry fit. And it's LIGHT.

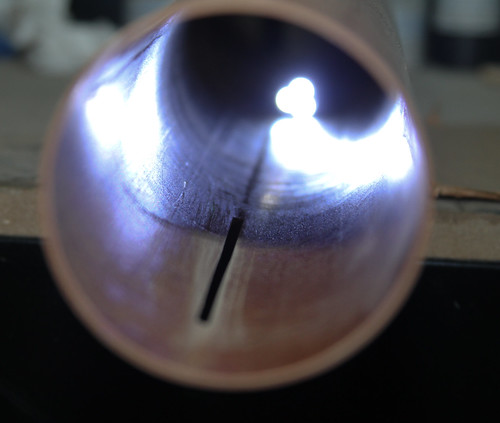

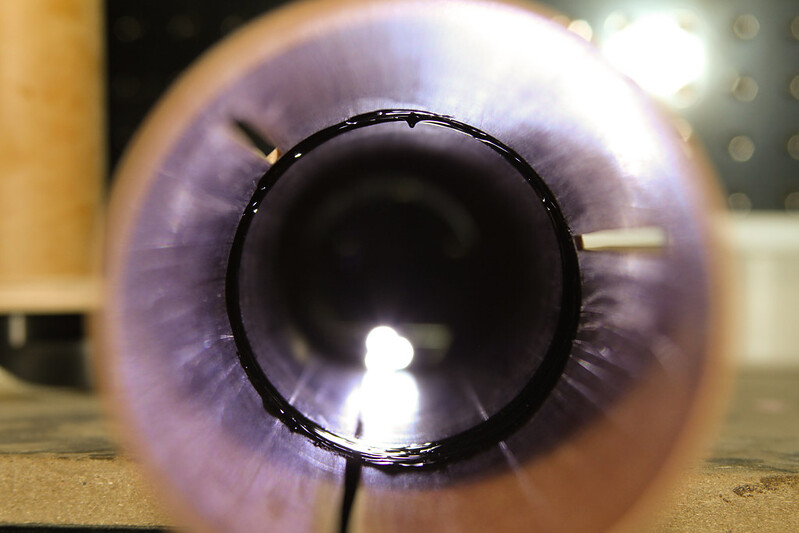

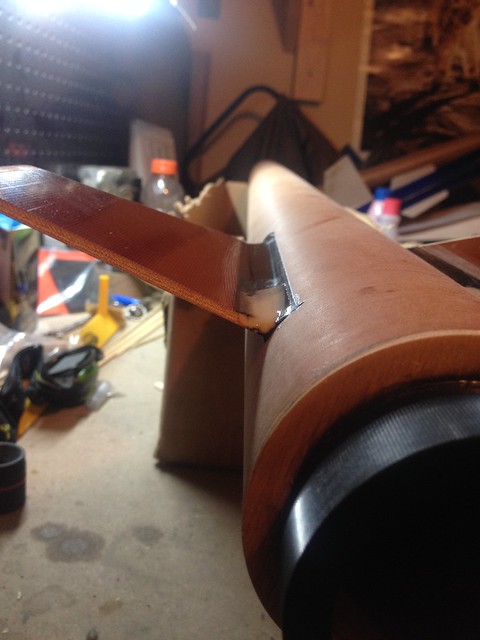

and the rear end. This will wear an aeropack, and may get foamed.

I'm busy with the holiday and LDRS cleanup still, but I wanted to get this open, snap a few pics and check it out. This will be a full build thread. So here we go.

Parts layout, including official LDRS mud on my table.

One of the canvas fins. Feels nice.

ALL DONE! OK not really...but this snapped together nicely for a dry fit. And it's LIGHT.

and the rear end. This will wear an aeropack, and may get foamed.

Last edited: