RKeller

Well-Known Member

- Joined

- Jul 31, 2014

- Messages

- 1,055

- Reaction score

- 24

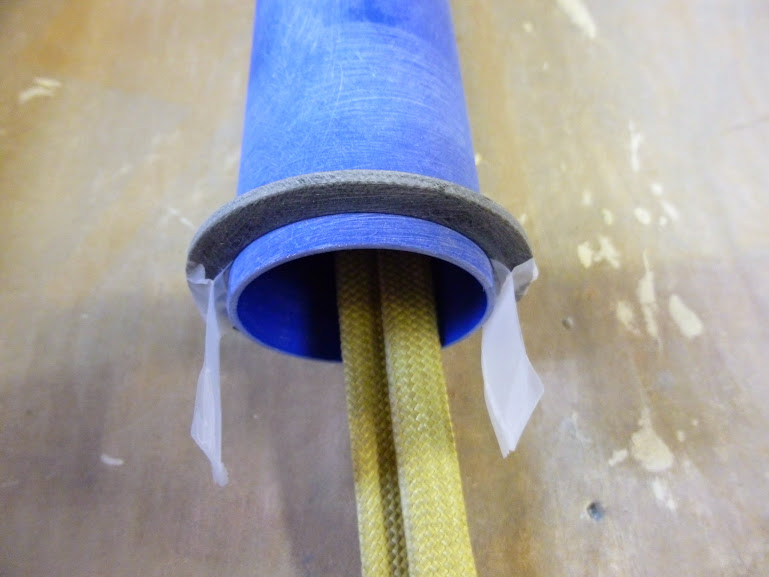

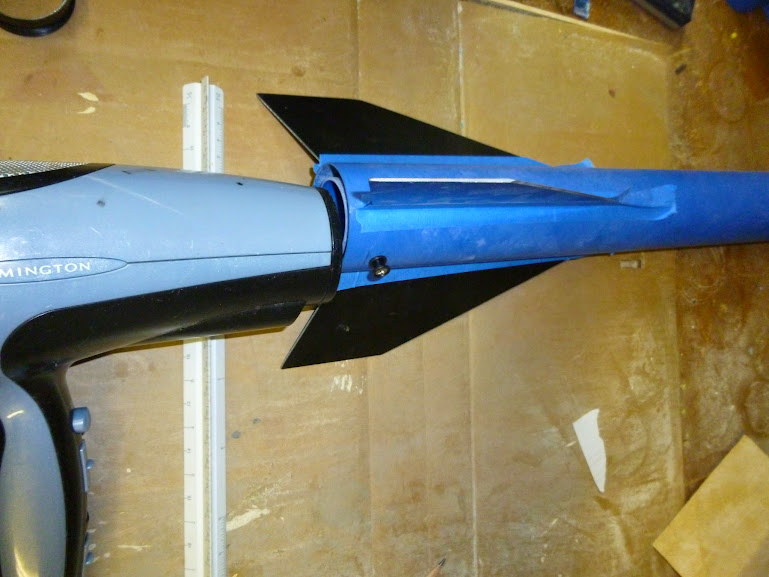

I picked up a scarab 54 with a 38mm motor tube during the Rocketry Warehouse black friday sale. I got a 38mm Aeropack motor retainer and some 5/16th kevlar for the Y harness. This kevlar is massive, defiantly overkill for this rocket but it's that or the 1/4" stuff that just seems a little wimpy, even though it would probably be fine.

The kevlar is tubular and relaxes to about 1/2". I pulled it taught, taped it, cut it, then put a drop of CA on the ends so they don't fray apart. I tacked down the ends of the kevlar with CA so I could pull it tight and glue it down.

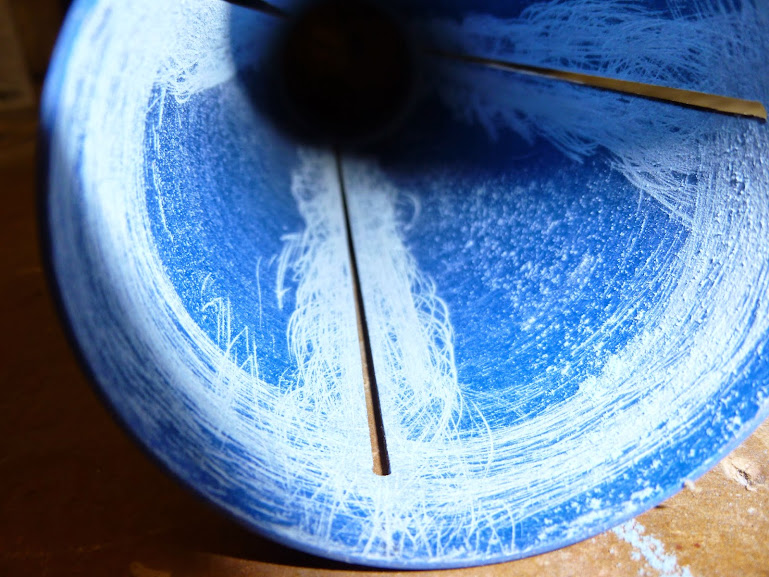

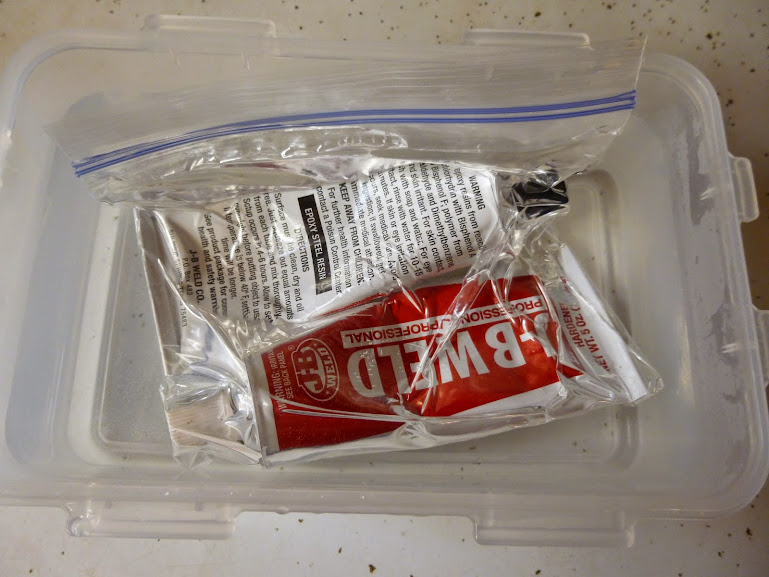

I applied JB weld under the kevlar, pulled it tight and taped the ends to the motor tube to keep them nice and tight against the tube then covered the kevlar with JB weld. I made sure to mark the centering ring where the fins will be so I didn't get any JB weld in the way.

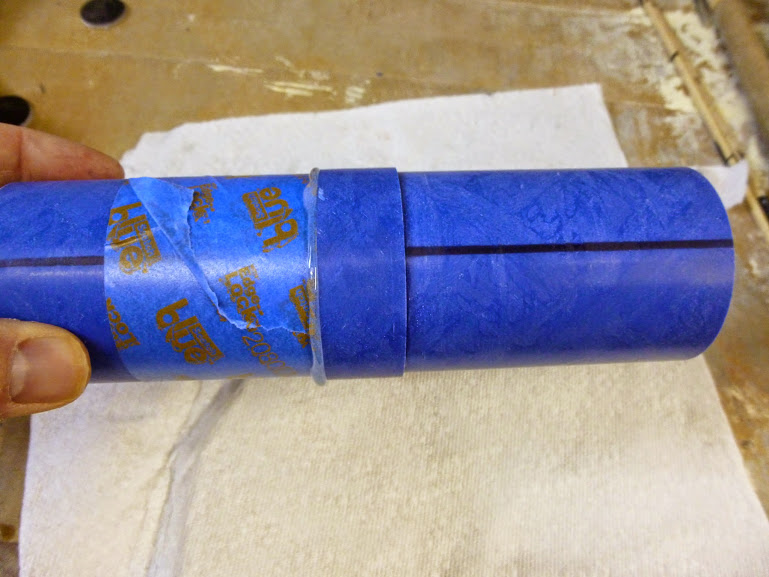

The rear centering ring and motor retainer are not glued on, just a tight fit so I can properly position the front centering ring. once the JB weld sets up I'll pull off the tape and put a nice fillet on the front of the centering ring.

The kevlar is tubular and relaxes to about 1/2". I pulled it taught, taped it, cut it, then put a drop of CA on the ends so they don't fray apart. I tacked down the ends of the kevlar with CA so I could pull it tight and glue it down.

I applied JB weld under the kevlar, pulled it tight and taped the ends to the motor tube to keep them nice and tight against the tube then covered the kevlar with JB weld. I made sure to mark the centering ring where the fins will be so I didn't get any JB weld in the way.

The rear centering ring and motor retainer are not glued on, just a tight fit so I can properly position the front centering ring. once the JB weld sets up I'll pull off the tape and put a nice fillet on the front of the centering ring.