RocketHunter

Well-Known Member

- Joined

- Jun 15, 2013

- Messages

- 390

- Reaction score

- 3

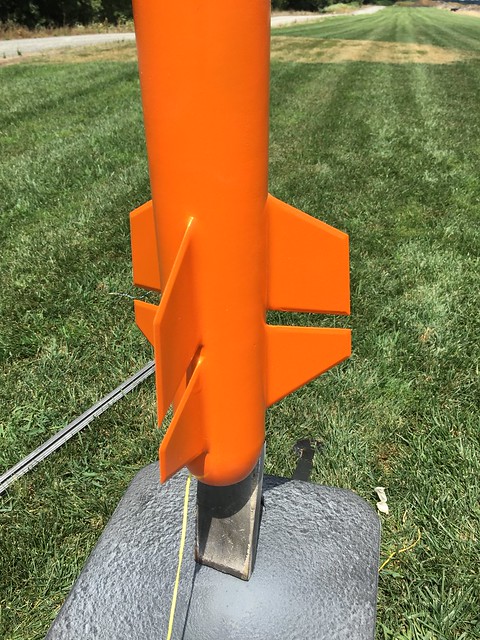

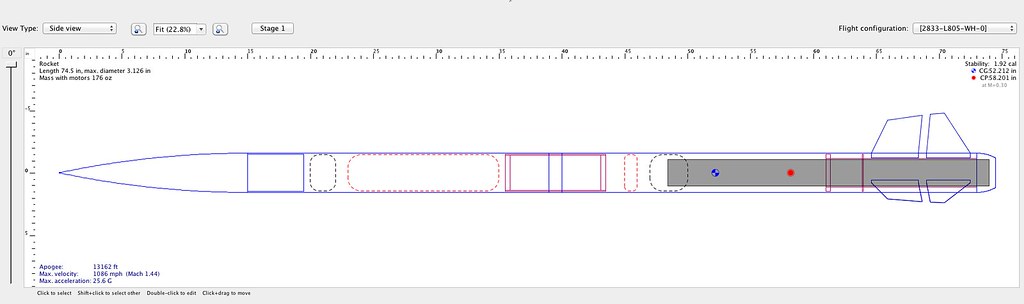

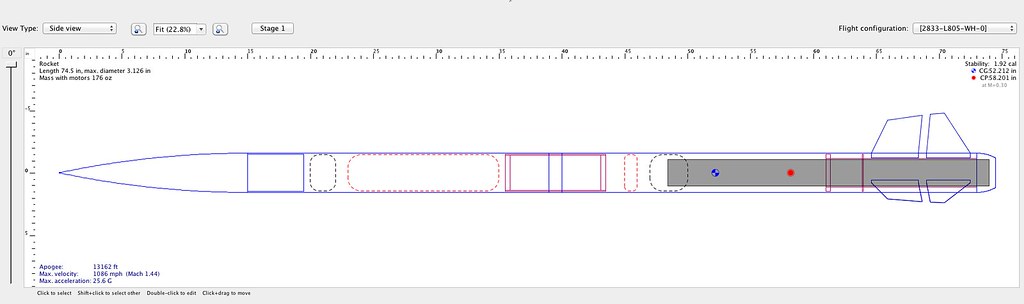

I will be doing a quick build thread for my "Beta" kit from MAC Performance - a 3'' diameter, split fin Rayzor. It has a 54mm motor mount and extended booster and payload tubes, meaning this puppy will hold 54mm 6GXl's and 54/2800's :grin:

I want to say a quick thank you to Mike at MAC Performance for giving me the opportunity to do this. I had the pleasure of meeting him at LDRS and had a really great time chatting about rocketry and his kits. :smile:

You can see the full parts listing and description on MAC Performance's website here (note: this kit is also available with a 38mm MMT):

https://shop.macperformancerocketry...products/rayzor-3-diameter?variant=2603945921

The kit showed up nicely packaged, just 2 days after being shipped.

While it seems almost repetitive to describe the quality of the kit and parts with the other MAC Performance build threads out there, I will reiterate that these kits are just perfect. This is my second kit from MAC Performance - my first was a 3'' ARCAS - and both have been nothing short of flawless. I had gotten other kits (mostly fiberglass) from quite a few other manufacturers that at the time I thought fit together nicely, but looking back now they just don't even compare to the quality of these kits.

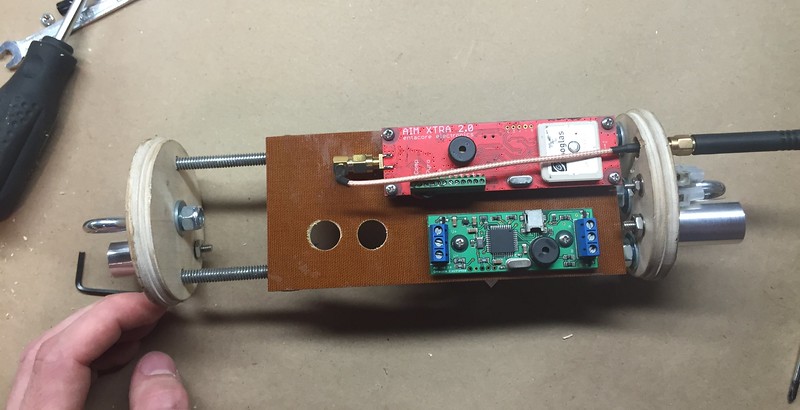

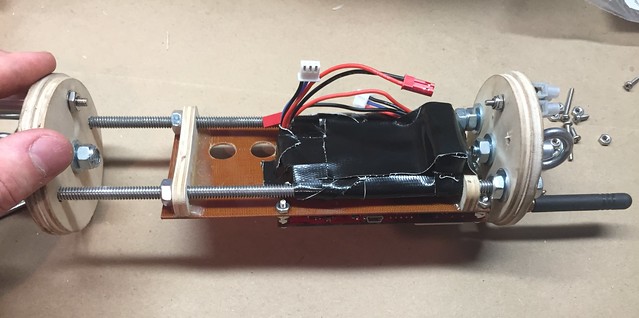

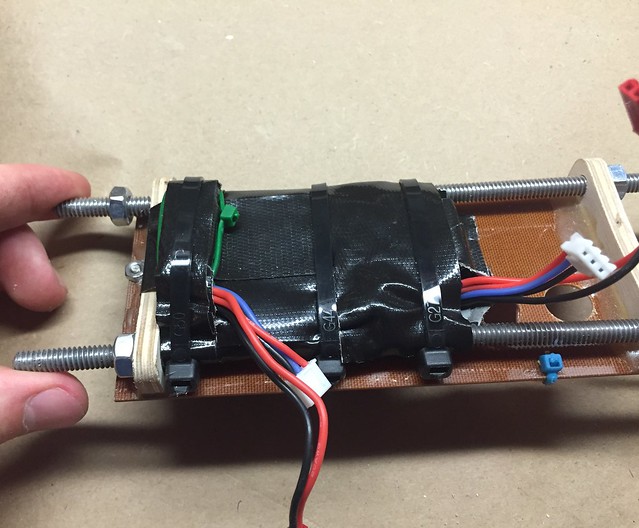

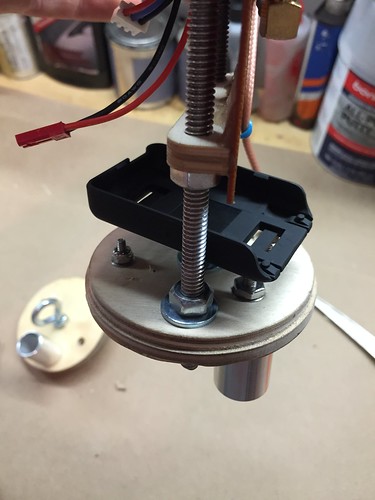

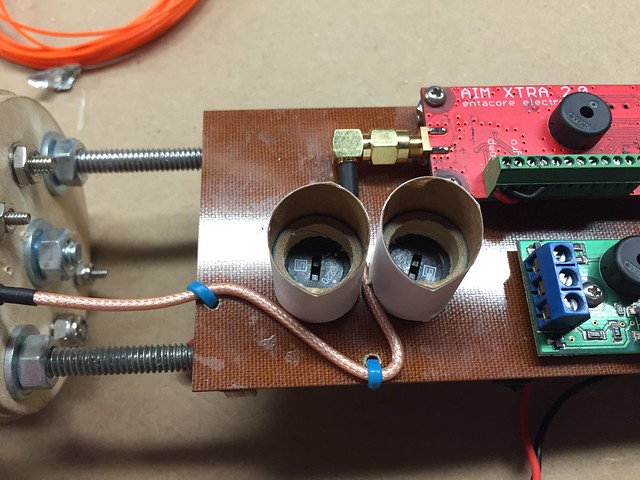

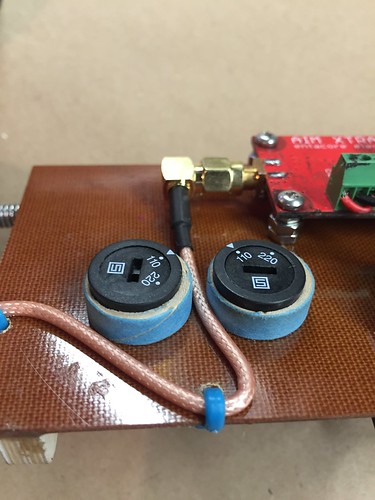

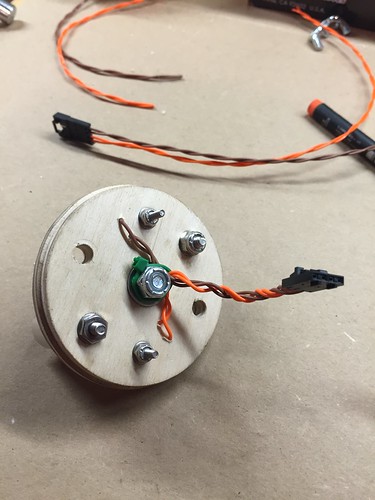

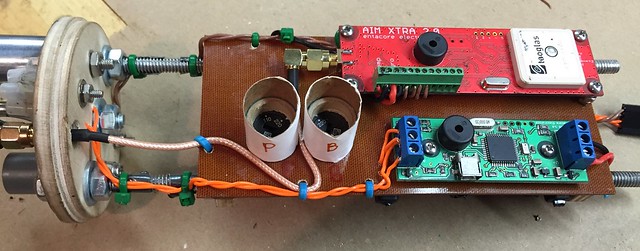

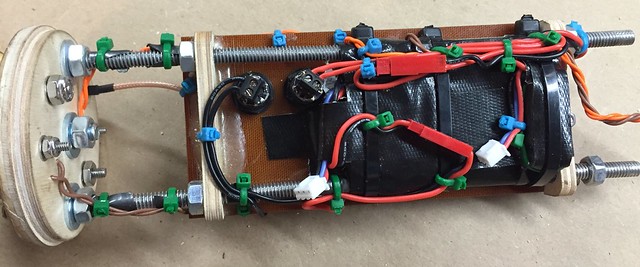

Moving on to the parts, one of my favorite features of MAC Performance kits are the altimeter bays. Included are eyebolts and associated hardware for each end of the electronics bay, pre-cut ALUMINUM threaded rod, sled standoffs and a lightweight canvas phenolic altimeter sled. The bulkheads are stepped, and a perfect fit into the coupler. This whole assembly makes for an easy to build, lightweight, and strong electronics bay.

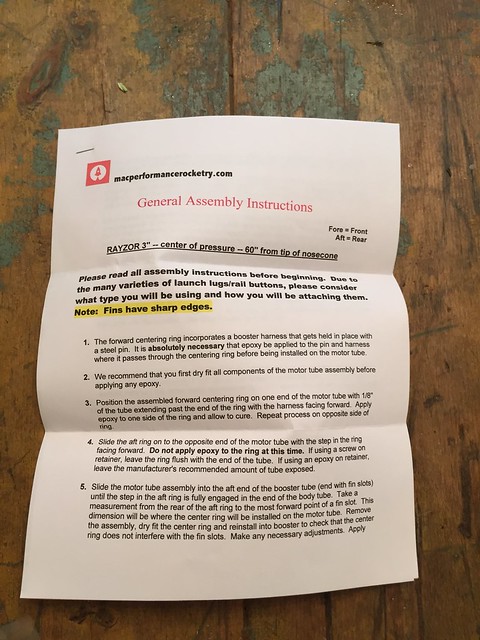

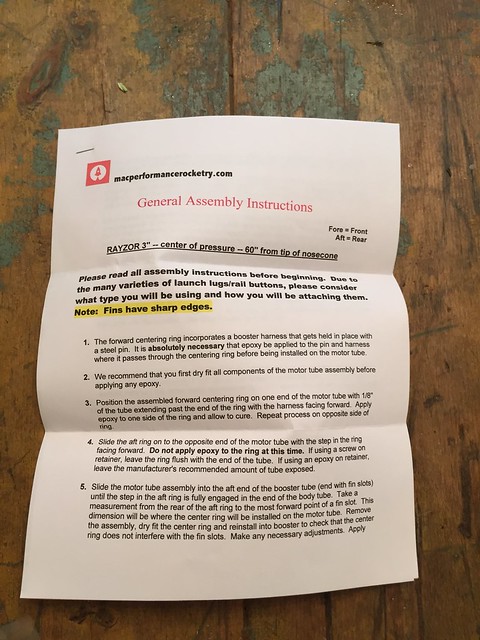

MAC Performance kits are just great for getting certifications (I got my L2 with one). They are durable, strong, really easy to build, and very complete. They even come with basic instructions to get you pointed in the right direction. Fly one single deploy on an H for L1, complete the electronics bay for dual deploy, pop a J in there for your L2, then let it rip on a 54mm baby L, all in one rocket!

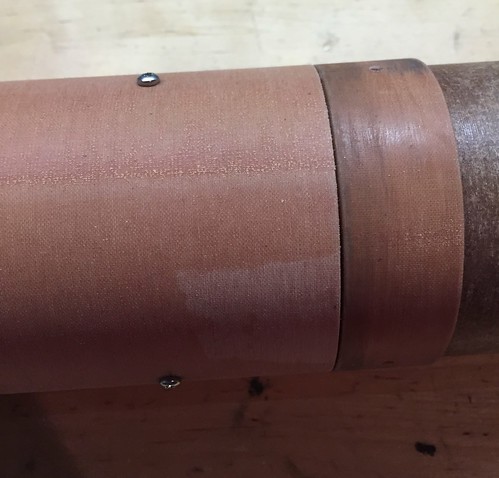

The tubing is very nice - similar in feel to the ubiquitous FWFG tubing, just half the weight and yet still very strong!

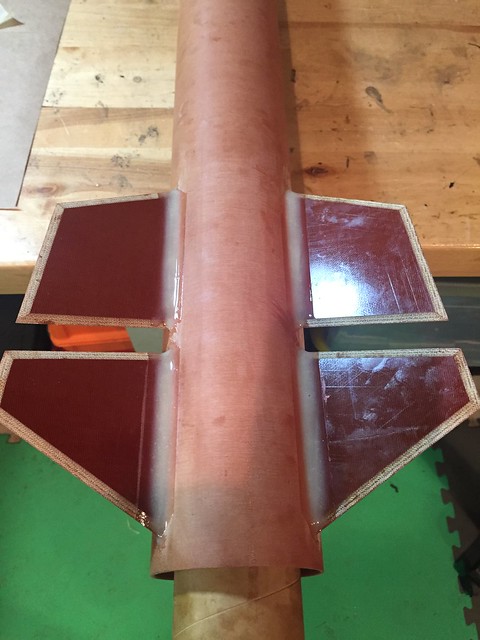

Now comes the fun part - the new Canvas Phenolic fins! They are 1/8'' thick (actually measured at 0.127''), and beautifully beveled. Personally, beveled fins are HUGE - not having to bevel them myself saves a ton of time, and they are better than I would ever get anyway! The canvas phenolic is much lighter than G10, and is still strong and stiff enough for M1.4+ flights on large 54mm motors.

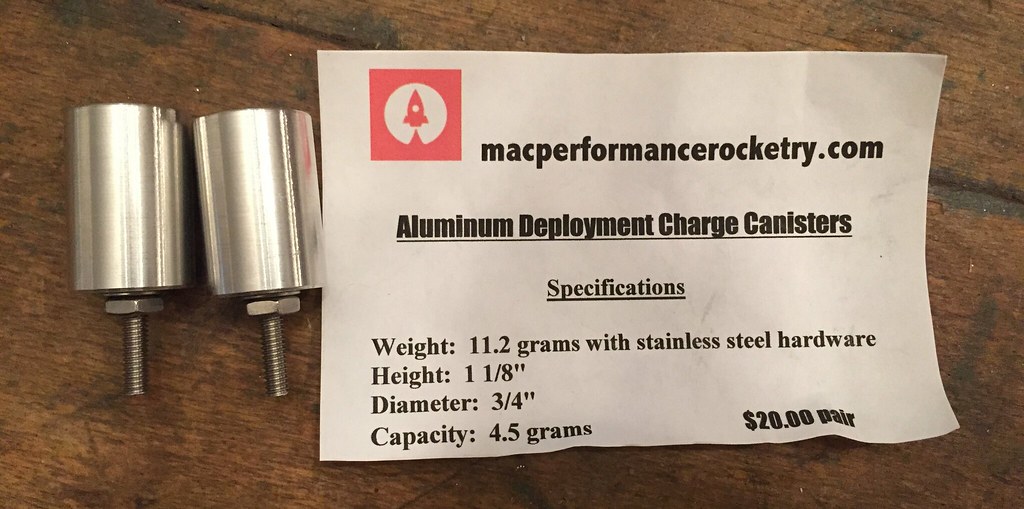

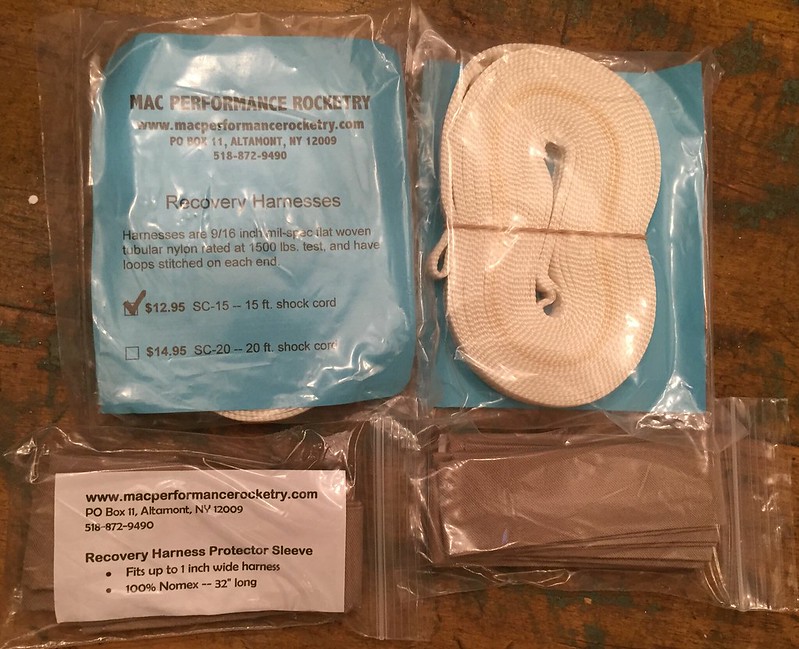

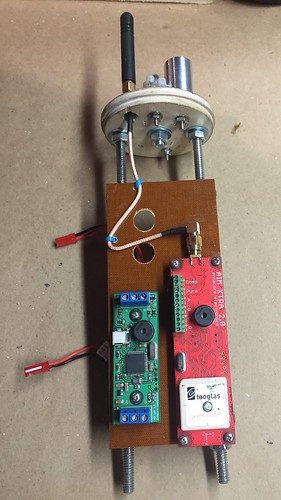

Now, onto my plans for this specific rocket. Dual Deploy and GPS tracking will be handled by an Entacore AIM XTRA unit (the one on the right below). With a full suite of inertial sensors, I'll be able to get GPS flight paths, altitude, velocity and acceleration plots, and even other things like vertical rotation (spin) with a bit more work. Currently I'm planning on going with the stock paint job (picture taken from MAC Performance website) as it is simple, and I don't have any other orange rockets :grin:

After this it will be a pretty succinct build thread as I'm hoping to get it built, though probably not painted, in time for my club's monthly July launch next saturday. If I make that deadline, I'm planning a flight or two on small J's to 4,500', just under our 5,000' waiver. Additionally, I'm hoping to make it to either the July or August URRG launch, where the 3'' Rayzor will fly on a CTI 2,856 n-s L805-White to really stretch its legs :grin:

View attachment Rayzor_MAC_Performance.ork

I want to say a quick thank you to Mike at MAC Performance for giving me the opportunity to do this. I had the pleasure of meeting him at LDRS and had a really great time chatting about rocketry and his kits. :smile:

You can see the full parts listing and description on MAC Performance's website here (note: this kit is also available with a 38mm MMT):

https://shop.macperformancerocketry...products/rayzor-3-diameter?variant=2603945921

The kit showed up nicely packaged, just 2 days after being shipped.

While it seems almost repetitive to describe the quality of the kit and parts with the other MAC Performance build threads out there, I will reiterate that these kits are just perfect. This is my second kit from MAC Performance - my first was a 3'' ARCAS - and both have been nothing short of flawless. I had gotten other kits (mostly fiberglass) from quite a few other manufacturers that at the time I thought fit together nicely, but looking back now they just don't even compare to the quality of these kits.

Moving on to the parts, one of my favorite features of MAC Performance kits are the altimeter bays. Included are eyebolts and associated hardware for each end of the electronics bay, pre-cut ALUMINUM threaded rod, sled standoffs and a lightweight canvas phenolic altimeter sled. The bulkheads are stepped, and a perfect fit into the coupler. This whole assembly makes for an easy to build, lightweight, and strong electronics bay.

MAC Performance kits are just great for getting certifications (I got my L2 with one). They are durable, strong, really easy to build, and very complete. They even come with basic instructions to get you pointed in the right direction. Fly one single deploy on an H for L1, complete the electronics bay for dual deploy, pop a J in there for your L2, then let it rip on a 54mm baby L, all in one rocket!

The tubing is very nice - similar in feel to the ubiquitous FWFG tubing, just half the weight and yet still very strong!

Now comes the fun part - the new Canvas Phenolic fins! They are 1/8'' thick (actually measured at 0.127''), and beautifully beveled. Personally, beveled fins are HUGE - not having to bevel them myself saves a ton of time, and they are better than I would ever get anyway! The canvas phenolic is much lighter than G10, and is still strong and stiff enough for M1.4+ flights on large 54mm motors.

Now, onto my plans for this specific rocket. Dual Deploy and GPS tracking will be handled by an Entacore AIM XTRA unit (the one on the right below). With a full suite of inertial sensors, I'll be able to get GPS flight paths, altitude, velocity and acceleration plots, and even other things like vertical rotation (spin) with a bit more work. Currently I'm planning on going with the stock paint job (picture taken from MAC Performance website) as it is simple, and I don't have any other orange rockets :grin:

After this it will be a pretty succinct build thread as I'm hoping to get it built, though probably not painted, in time for my club's monthly July launch next saturday. If I make that deadline, I'm planning a flight or two on small J's to 4,500', just under our 5,000' waiver. Additionally, I'm hoping to make it to either the July or August URRG launch, where the 3'' Rayzor will fly on a CTI 2,856 n-s L805-White to really stretch its legs :grin:

View attachment Rayzor_MAC_Performance.ork

Last edited: