MikeyDSlagle

Well-Known Member

- Joined

- Dec 16, 2013

- Messages

- 2,591

- Reaction score

- 572

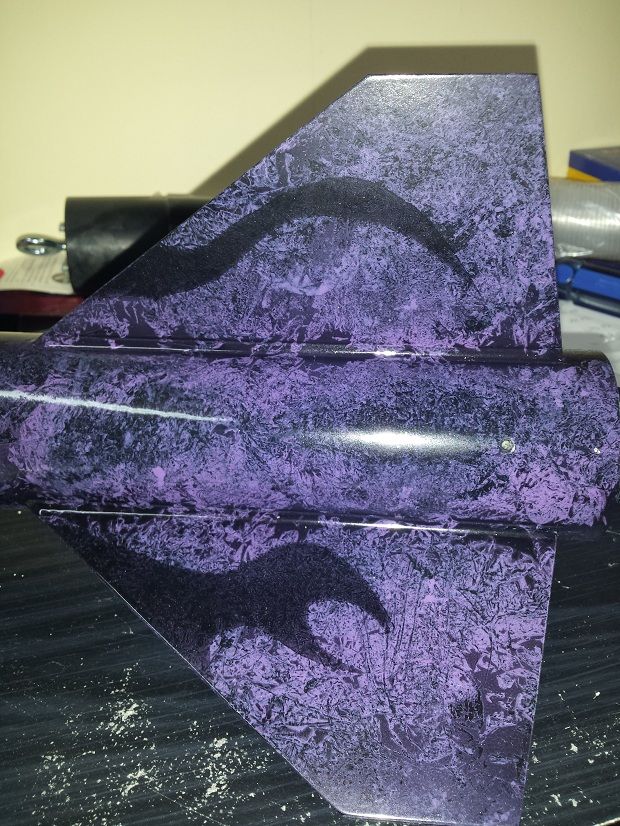

Hello all. Don't think I have done a build thread yet so I thought I would do one of my Wildman sport. There probably won't be a whole lot of innovative ideas here but maybe someone will enjoy reading the thread. I thought I would document the build because it is my first fiberglass kit. My girlfriend got the kit for me for my birthday and there has been comments like "that's all that is in there...for that price", "no instructions!!??" just to name a couple so it will probably be my last fiberglass build as well :lol: And I got a pretty awful look when I mentioned the price for a wrap from Stickershock. Looks like I will be painting this one myself.

The Wildman Sport is a nice kit. The nose cone had a few rings that needed sanded but took only a moment to get em sanded smooth.

Everything sanded and ready to go. Sanded 2 notches in the forward centering ring for the shock cord mount. I usually put the notches on the outside so the shock cord would be out of the way of the initial blast from the ejection charge. I'm using heavier cord on this one and this seems like it would be a stronger mount.

View attachment 257853

My goodies from Sirius Rocketry. They got my parts to me really fast. That was nice.

View attachment 257854

I decided to go with the PML HAMR 29 over the Aeropack because I like the fine threads of the HAMR. (and I like saying HAMR LOL) They are pretty much the same otherwise, even price. I had doubts as to whether or not it would fit but it fits really nice with just enough slop for the JB Weld.

View attachment 257855

And finally my goody bag from Rocketry Warehouse. I had intended to use the purple shock cord attached to a few feet of the kevlar but the it weighed in at 2.5 oz. The final weight will determine if it gets used or not. I could have done without the huge swivel. But oh well. I ordered the Delrin buttons with countersunk heads for this build but they sent the ones with plain round heads anyway. The buttons themselves are countersunk but the screws aren't. I hope to eventually use a cable cutter for dual deploy with this rocket hence the piece of G10 for a sled. That's a 38mm bulkhead that I will use in the nose cone. Also got me some reusable rivets... not sure if I will use em for anything. But ya never know.

View attachment 257856

The Wildman Sport is a nice kit. The nose cone had a few rings that needed sanded but took only a moment to get em sanded smooth.

Everything sanded and ready to go. Sanded 2 notches in the forward centering ring for the shock cord mount. I usually put the notches on the outside so the shock cord would be out of the way of the initial blast from the ejection charge. I'm using heavier cord on this one and this seems like it would be a stronger mount.

View attachment 257853

My goodies from Sirius Rocketry. They got my parts to me really fast. That was nice.

View attachment 257854

I decided to go with the PML HAMR 29 over the Aeropack because I like the fine threads of the HAMR. (and I like saying HAMR LOL) They are pretty much the same otherwise, even price. I had doubts as to whether or not it would fit but it fits really nice with just enough slop for the JB Weld.

View attachment 257855

And finally my goody bag from Rocketry Warehouse. I had intended to use the purple shock cord attached to a few feet of the kevlar but the it weighed in at 2.5 oz. The final weight will determine if it gets used or not. I could have done without the huge swivel. But oh well. I ordered the Delrin buttons with countersunk heads for this build but they sent the ones with plain round heads anyway. The buttons themselves are countersunk but the screws aren't. I hope to eventually use a cable cutter for dual deploy with this rocket hence the piece of G10 for a sled. That's a 38mm bulkhead that I will use in the nose cone. Also got me some reusable rivets... not sure if I will use em for anything. But ya never know.

View attachment 257856

Last edited: