V2rocketeer

Well-Known Member

- Joined

- Jul 29, 2012

- Messages

- 211

- Reaction score

- 0

Hi All

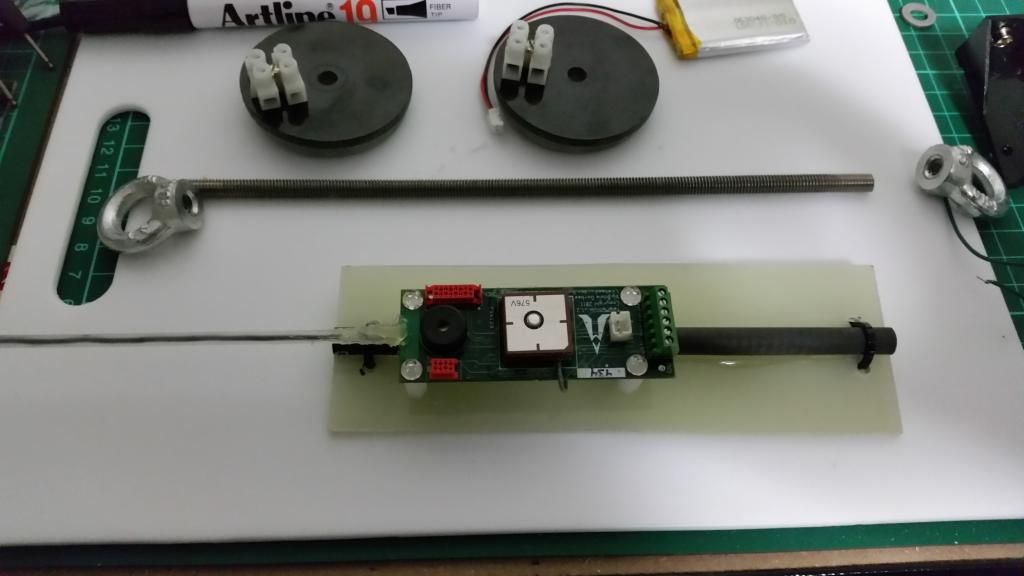

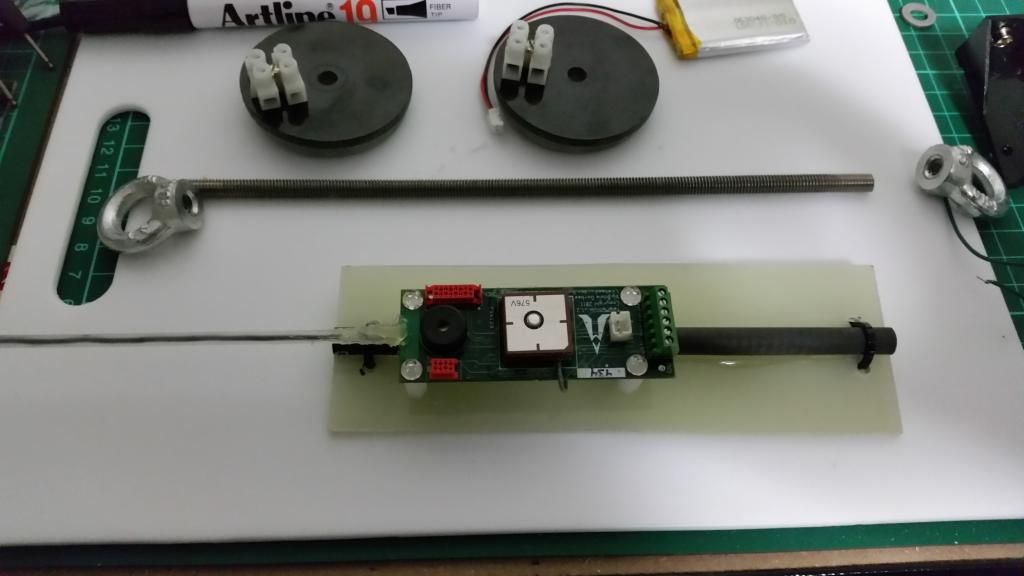

I'm installing a Telemetrum 1.2 into a MD 54mm bird that will be pushed hard with big motors.

My ebay has a central threaded rod to hold the ends together. To avoid or at least reduce the antenna of the

Telemetrum from coupling with with the rod I have epoxied a section of carbon tubing that should encase the

threaded rod. Yes this will in some way block some of the RF but I think that locating the altimeter with a majority

of the antenna poking out into the next bay should assist with that. I was under the impression that the Telemetrum

had to be antenna up in its installation. I see in the AltOs configure Altimeter that there is an option to configure the

altimeters orientation. Can the Telemetrum be mounted upside down? It suits me better as I can run the antenna

into the drogue bay which will not have a drogue and have less to tangle with than in the main bay with the chute.

So my 2 questions are.

Is there any problem running the Telemetrum as shown below with the threaded rod covered by a carbon rod ?

Can the Telemetrum V1.2 be mounted upside down?

I will do some ground testing of the RF signal from the Telemetrum but was curious if anyone else had tried this?

73

Chris vk2icj

I'm installing a Telemetrum 1.2 into a MD 54mm bird that will be pushed hard with big motors.

My ebay has a central threaded rod to hold the ends together. To avoid or at least reduce the antenna of the

Telemetrum from coupling with with the rod I have epoxied a section of carbon tubing that should encase the

threaded rod. Yes this will in some way block some of the RF but I think that locating the altimeter with a majority

of the antenna poking out into the next bay should assist with that. I was under the impression that the Telemetrum

had to be antenna up in its installation. I see in the AltOs configure Altimeter that there is an option to configure the

altimeters orientation. Can the Telemetrum be mounted upside down? It suits me better as I can run the antenna

into the drogue bay which will not have a drogue and have less to tangle with than in the main bay with the chute.

So my 2 questions are.

Is there any problem running the Telemetrum as shown below with the threaded rod covered by a carbon rod ?

Can the Telemetrum V1.2 be mounted upside down?

I will do some ground testing of the RF signal from the Telemetrum but was curious if anyone else had tried this?

73

Chris vk2icj

Last edited: