dcbertelsen

Well-Known Member

- Joined

- May 4, 2009

- Messages

- 421

- Reaction score

- 3

A quick update.

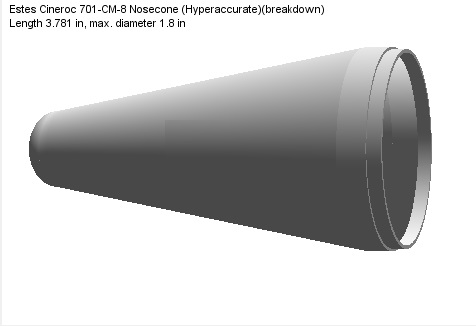

Nosecone was printed today in ABS (mostly to determine print settings). The model was still pretty rough; there was a small offset where the rounded tip met and no shoulder. We have a few small tweaks to try but the entire cone printed and everything seems structurally sound. I have revision 2; a more accurate model complete with shoulder and fully filled tip that smoothly transitions to the cone. I will be in tomorrow morning doing some work and will attempt a print.

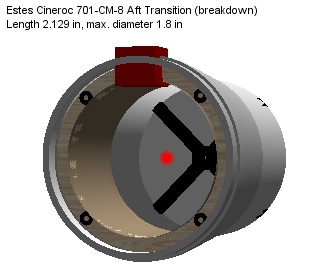

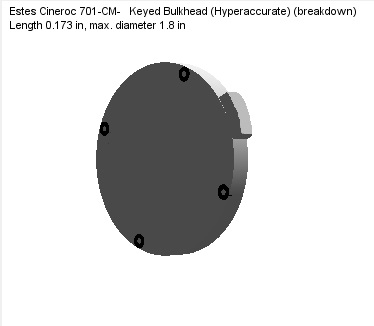

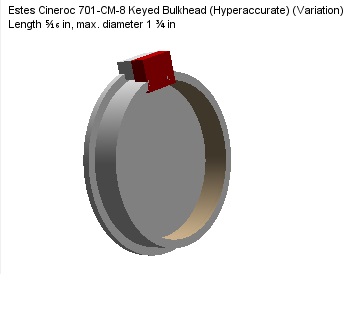

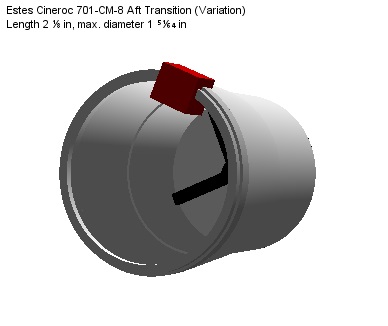

The bulkhead should be ready to print. We still don't have the lower transition, but that shouldn't take too much.

With the direction this thread has taken, it might be a good idea to move it elsewhere on the forum. Any thoughts?

Doug

Nosecone was printed today in ABS (mostly to determine print settings). The model was still pretty rough; there was a small offset where the rounded tip met and no shoulder. We have a few small tweaks to try but the entire cone printed and everything seems structurally sound. I have revision 2; a more accurate model complete with shoulder and fully filled tip that smoothly transitions to the cone. I will be in tomorrow morning doing some work and will attempt a print.

The bulkhead should be ready to print. We still don't have the lower transition, but that shouldn't take too much.

With the direction this thread has taken, it might be a good idea to move it elsewhere on the forum. Any thoughts?

Doug