You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3D printing Challenge

- Thread starter Brent

- Start date

Help Support The Rocketry Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

terryg

Well-Known Member

Now that would be really cool!

PhlAsh

Well-Known Member

- Joined

- May 9, 2011

- Messages

- 1,202

- Reaction score

- 239

I would love to see this challenge taken up... the Nike Hercules is my all-time favorite missile.

rocketguy101

Well-Known Member

- Joined

- Jan 17, 2009

- Messages

- 1,476

- Reaction score

- 114

nice, what is the top diameter (the Herc end)? I have dwgs of the Nike M5 motor. I don't have a 3D printer but would like to attempt to model in Solidworks, and will put stl files out for those interested...I have photos from the Ft Sill Museum.

Attachments

Winston

Lorenzo von Matterhorn

- Joined

- Jan 31, 2009

- Messages

- 9,560

- Reaction score

- 1,748

Maybe contact this guy?I have a challenge for someone with a 3D printer . How about the transition for the Nike Hercules. Make it around 2" or even better 3" Nike Booster tubes. I have a print but don't have the time or 3D design software.

https://www.etsy.com/shop/RocketryCNC?ref=shopinfo_shophome_leftnav

simonov

Well-Known Member

- Joined

- Nov 11, 2014

- Messages

- 57

- Reaction score

- 0

If you could get a better resolution image, I could whip up a model pretty easily.

rocketguy101

Well-Known Member

- Joined

- Jan 17, 2009

- Messages

- 1,476

- Reaction score

- 114

25.376" at the top

Give this a few minutes to sync - Herc.zip

There's a Peter Alway dwg in there that has mismatched dimensions but, since he cites the other sketches, that's what I'd go with...

Here is some great data on the Nike motor and a nice shot of the N-H transition... https://meatballrocketry.com/nike-motor-data/

rocketguy101

Well-Known Member

- Joined

- Jan 17, 2009

- Messages

- 1,476

- Reaction score

- 114

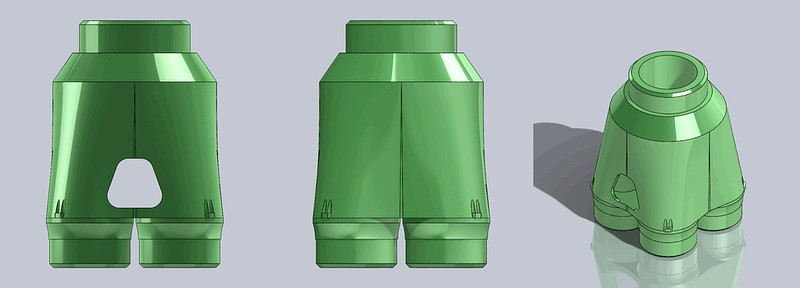

Here is what I got so far, I don't think I have the weld lines on the Nike motors oriented correctly as the holes in the top of the motor don't line up ... I will look at it some more tonight when I get home. Also, I "shelled" the transition out to be hollow like the real thing, but for modeling purposes, you might want it solid.

simonov

Well-Known Member

- Joined

- Nov 11, 2014

- Messages

- 57

- Reaction score

- 0

Looks like that's all I need. It will be tonight's project, Project Momaday (my project names are selected from a random list; I have no idea what "Momaday" means).25.376" at the top

Give this a few minutes to sync - Herc.zip

I assume the dimensions are inches?

rharshberger

Well-Known Member

Here is what I got so far, I don't think I have the weld lines on the Nike motors oriented correctly as the holes in the top of the motor don't line up ... I will look at it some more tonight when I get home. Also, I "shelled" the transition out to be hollow like the real thing, but for modeling purposes, you might want it solid.

That looks nice, I might be interested in one scaled for the TLP Nike Hercules Plan Pak, where I plan on using ST-20s for my booster tubes.

simonov

Well-Known Member

- Joined

- Nov 11, 2014

- Messages

- 57

- Reaction score

- 0

I thought I would be able to provide a solid model scaled to the OP's desired tube dimensions, but a family crisis just occurred and I have to get away from a few hours.

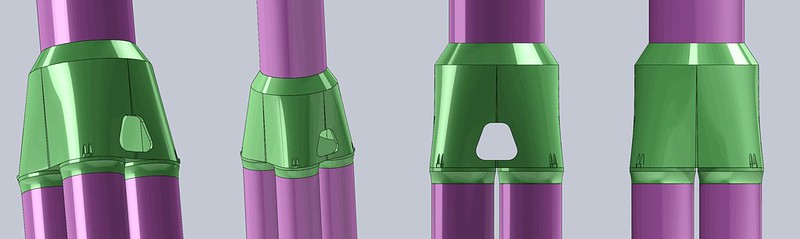

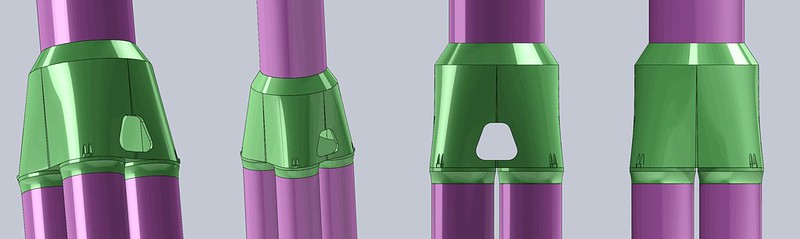

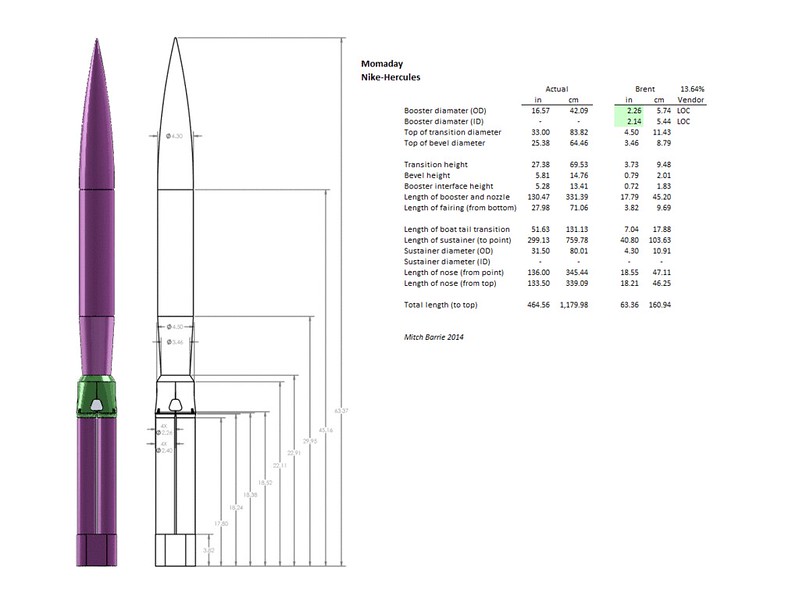

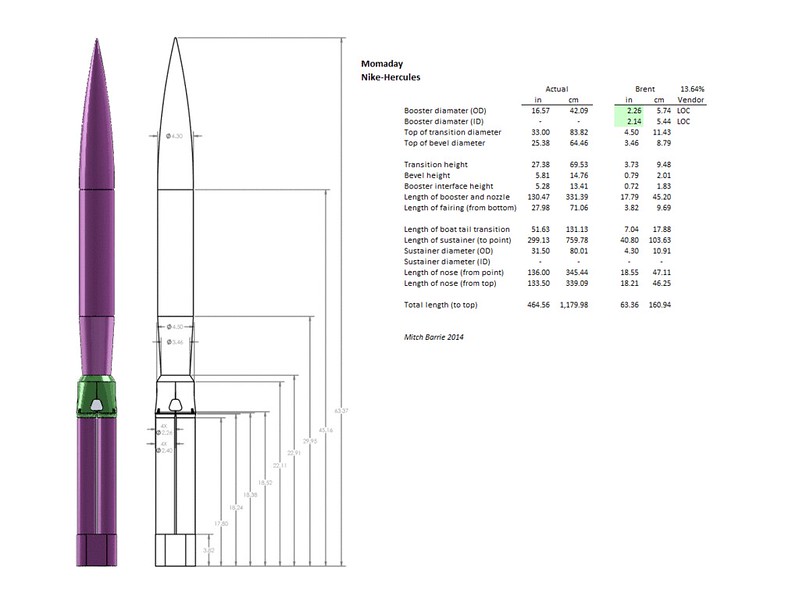

Anyway, here is my go:

The transition is green, the boosters and upper stage are pink. Once this was scaled to match tube sizes, shoulders would be added at top and bottom to accommodate the tubes. The transition is hollow, as the actual one seemed to be, but I'm not sure what's going on inside. It would be easy enough to add that detail.

Anyway, here is my go:

The transition is green, the boosters and upper stage are pink. Once this was scaled to match tube sizes, shoulders would be added at top and bottom to accommodate the tubes. The transition is hollow, as the actual one seemed to be, but I'm not sure what's going on inside. It would be easy enough to add that detail.

simonov

Well-Known Member

- Joined

- Nov 11, 2014

- Messages

- 57

- Reaction score

- 0

simonov

Well-Known Member

- Joined

- Nov 11, 2014

- Messages

- 57

- Reaction score

- 0

I'll upload the file to my website.Ready to buy when available

What format do you need?

And did my dimensional choices make sense? I used what I thought were standard sizes I found in the OpenRocket database.

Edit: after reviewing more photos of the Nike Hercules, I don't think we are done yet. The top of the transition is directly into a boat tail shaped main fuselage (I had assumed it was a straight cylinder). How do you intend to do the boat tail? Or should that be incorporated into the part?

Last edited:

Looking good so far... The boat tail in the upper section will have to be built into the sustainer, seeing the Nike Hercules sustainer resembles a cigar contour of sorts:

simonov

Well-Known Member

- Joined

- Nov 11, 2014

- Messages

- 57

- Reaction score

- 0

What I propose to do is model the boat tail as a separate part that can be mated to the transition piece. While I am at it, I could model slots for the fins into the boat tail.

The model I showed above is not correct. I misunderstood brent's request and found a tube that was close to 54mm. In fact, it's too small to accept a 54mm motor.

So what I need are diameter dimensions for the booster tubes, based on standard sizes. Also, desired fin stock thickness, if I'm going to model slots in the boat tail. You guys tell me what you need, and I can scale the parts as needed. But I'm a rocketry n00b, so you have to give me the tube specs for the four boosters. I can work out the rest. I'll put all this in a spreadsheet so there is no confusion.

The model I showed above is not correct. I misunderstood brent's request and found a tube that was close to 54mm. In fact, it's too small to accept a 54mm motor.

So what I need are diameter dimensions for the booster tubes, based on standard sizes. Also, desired fin stock thickness, if I'm going to model slots in the boat tail. You guys tell me what you need, and I can scale the parts as needed. But I'm a rocketry n00b, so you have to give me the tube specs for the four boosters. I can work out the rest. I'll put all this in a spreadsheet so there is no confusion.

Brent

Well-Known Member

- Joined

- Jan 19, 2009

- Messages

- 1,762

- Reaction score

- 129

The 2.0" tubing would be fine as long as it can be found. Personally I am thinking a cluster of 4 29 or 38 in the booster. The main sustainer tube I am thinking 4". at least that is what I have drawn in RocKSim. Here are the common tube ID and OD: 54 mm Loc 2.14 ID 2.26 OD, PML 2.15 ID 2.28 OD. The 2" tubing is 2.0 ID and 2.040 OD. ( I have got it in the past from Semroc ) The Sustainer tubing Loc 3.9 ID and 4.0 OD. PML 3.9 ID and 4.020 OD.

rocketguy101

Well-Known Member

- Joined

- Jan 17, 2009

- Messages

- 1,476

- Reaction score

- 114

WOW that is really nice! I wasn't modeling the tops of the M5 motors as part of the transition, but I like what you did. I had problems last night trying to get the holes for the bolts that attach the transition to the M5 motors right. either my dimensions for the mating holes in the top of the motor are incorrect, or the dimensions in the gifs are off. what I came up with didn't look right.

What software are you using to model this?

Edit: added pics. Compare the side view to the photo on the meatball rocketry website. The other shot is the top of the M5 motor...there are three sets of 1/2" bolt holes, 120 deg apart.

Last edited:

Don't forget about the diamond airfoil booster fins... We'll need some nice prints of these as well... or am I getting ahead of the program(?)

Nice work with the solid modeling, the transition is looking great!

Nice work with the solid modeling, the transition is looking great!

rocketguy101

Well-Known Member

- Joined

- Jan 17, 2009

- Messages

- 1,476

- Reaction score

- 114

Don't forget about the diamond airfoil booster fins... We'll need some nice prints of these as well... or am I getting ahead of the program(?)

Nice work with the solid modeling, the transition is looking great!

I think it would be easier to make built-up fins rather than print them...you can use "ribs and skin" for the diamond (pictured below for my "F" powered Terrier-Sandhawk) or a "core and skin" for the double diamond like the Nike Smoke. I used balsa and 110# cardstock soaked with CA.

PhlAsh

Well-Known Member

- Joined

- May 9, 2011

- Messages

- 1,202

- Reaction score

- 239

It looks like Jim Ball's website got et when RocketryOnline folded. Here's a link to tide you over...

../jimball/jimball/scale-data/scale.htm

../jimball/jimball/scale-data/scale.htm

simonov

Well-Known Member

- Joined

- Nov 11, 2014

- Messages

- 57

- Reaction score

- 0

I wasn't aware in the beginning this was going to be a two-stage rocket. I'm not sure the SLA materials will hold up to the thrust from the sustainer. We might want to think about separating the rocket below the transition. Anyway, food for thought.

As promised, I started a spreadsheeet with key dimensions. Once you have decided on a standard tube size, you can use the spreadsheet top scale the entire model:

So using the LOC tubes specified by Brent for the boosters, you arrive at a scaling factor of 13.64%, or 1:7.33. The next step is to select a sustainer tube with an OD close to 4.30 inches. Once I have that I can tweak the scaled down model and we'll have something that can be made with off the shelf parts (though I still don't know what you want to do about the boat tail; that could be modeled and 3D printed, if desired, with the usual caveats about heat and SLA material).

(look at the actual size if you want to read the numbers).

Rocketguy, I use SolidWorks to model this stuff. The four pairs of bolts at the base of the transition are in a little boss that is slightly proud of the diameter of the transition, I think that's where yours and mine differ. I'm not sure whether details that small can be printed, and I'm pretty sure nothing smaller can be.

Anything can be modeled and printed, but I'd agree the fins are best done with wood or paper or some combination. 3D printing them would be expensive and heavy.

As promised, I started a spreadsheeet with key dimensions. Once you have decided on a standard tube size, you can use the spreadsheet top scale the entire model:

Code:

Momaday - Nike-Hercules Actual Brent (13.64%)

in cm in cm Vendor

-----------------------------------------

Booster diamater (OD) 16.57 42.09 2.26 5.74 LOC

Booster diamater (ID) - - 2.14 5.44 LOC

Top of transition diameter 33.00 83.82 4.50 11.43

Top of bevel diameter 25.38 64.46 3.46 8.79

Transition height 27.38 69.53 3.73 9.48

Bevel height 5.81 14.76 0.79 2.01

Booster interface height 5.28 13.41 0.72 1.83

Length of booster and nozzle 130.47 331.39 17.79 45.20

Length of fairing (from bottom) 27.98 71.06 3.82 9.69

Length of boat tail transition 51.63 131.13 7.04 17.88

Length of sustainer (to point) 299.13 759.78 40.80 103.63

Sustainer diameter (OD) 31.50 80.01 4.30 10.91

Sustainer diameter (ID) - - - -

Length of nose (from point) 136.00 345.44 18.55 47.11

Length of nose (from top) 133.50 339.09 18.21 46.25

Total length (to top) 464.56 1,179.98 63.36 160.94So using the LOC tubes specified by Brent for the boosters, you arrive at a scaling factor of 13.64%, or 1:7.33. The next step is to select a sustainer tube with an OD close to 4.30 inches. Once I have that I can tweak the scaled down model and we'll have something that can be made with off the shelf parts (though I still don't know what you want to do about the boat tail; that could be modeled and 3D printed, if desired, with the usual caveats about heat and SLA material).

(look at the actual size if you want to read the numbers).

Rocketguy, I use SolidWorks to model this stuff. The four pairs of bolts at the base of the transition are in a little boss that is slightly proud of the diameter of the transition, I think that's where yours and mine differ. I'm not sure whether details that small can be printed, and I'm pretty sure nothing smaller can be.

Anything can be modeled and printed, but I'd agree the fins are best done with wood or paper or some combination. 3D printing them would be expensive and heavy.

Last edited:

simonov

Well-Known Member

- Joined

- Nov 11, 2014

- Messages

- 57

- Reaction score

- 0

I wasn't actually planning 2 stage although that would be cool. I am not sure the abs plastic would hold up to staging. 4 38mm motors will give some respectable altitude. I am thinking dual deploy.

That makes it easy. What's a tube spec that is close to an OD of 4.3 inches?

Similar threads

- Replies

- 7

- Views

- 207