AlnessW

Well-Known Member

- Joined

- Oct 6, 2013

- Messages

- 1,221

- Reaction score

- 3

Cool - thanks guys!

For the nosecone of this rocket, I'll be using the tried-and-true Vern Knowles-style system. (My standard for ALL nosecones.)

Here we have all of the hardware I'll be using on the nosecone - 1/4" eyebolt with nuts/washers, 2.5" #10-24 machine screws, 1/2" #10-24 machine screws, and some #10-24 hex couplers.

I know, I know, 4 x 2.5" long screws is way overkill for a 54mm nosecone. But this is the exact same method I always use, so why re-invent the wheel...

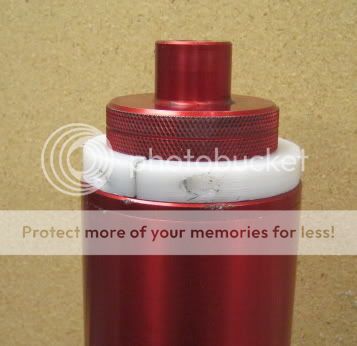

Bulkhead inserted into place. As you can see, doing the nosecone anchors BEFORE you glue the coupler in makes it a lot easier since you can access both sides.

First, we tack them in place using hobby epoxy.

And ready for the next step!

For the nosecone of this rocket, I'll be using the tried-and-true Vern Knowles-style system. (My standard for ALL nosecones.)

Here we have all of the hardware I'll be using on the nosecone - 1/4" eyebolt with nuts/washers, 2.5" #10-24 machine screws, 1/2" #10-24 machine screws, and some #10-24 hex couplers.

I know, I know, 4 x 2.5" long screws is way overkill for a 54mm nosecone. But this is the exact same method I always use, so why re-invent the wheel...

Bulkhead inserted into place. As you can see, doing the nosecone anchors BEFORE you glue the coupler in makes it a lot easier since you can access both sides.

First, we tack them in place using hobby epoxy.

And ready for the next step!