simonov

Well-Known Member

- Joined

- Nov 11, 2014

- Messages

- 57

- Reaction score

- 0

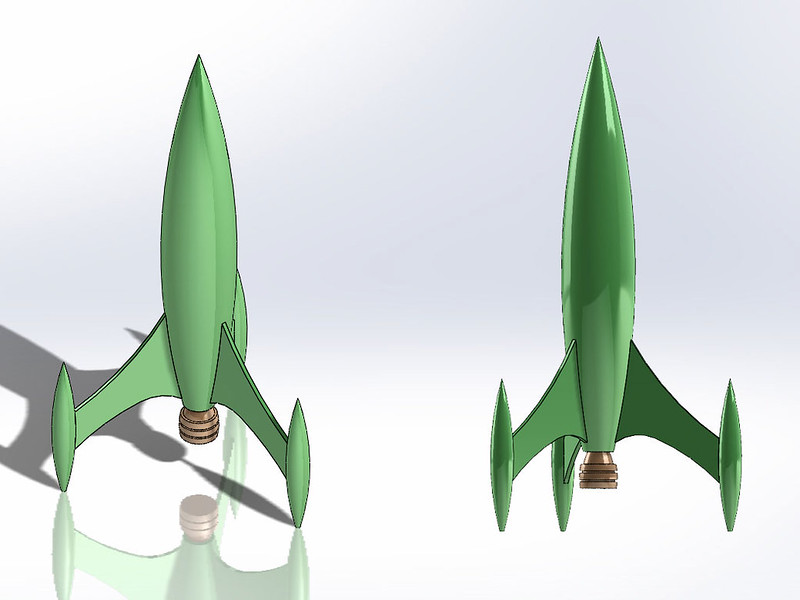

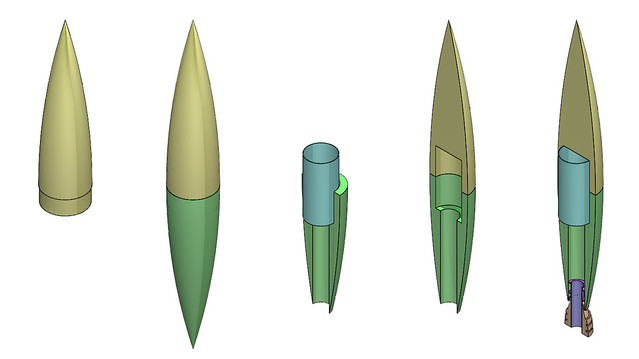

I noticed this fanciful design in dixontj93060's avatar:

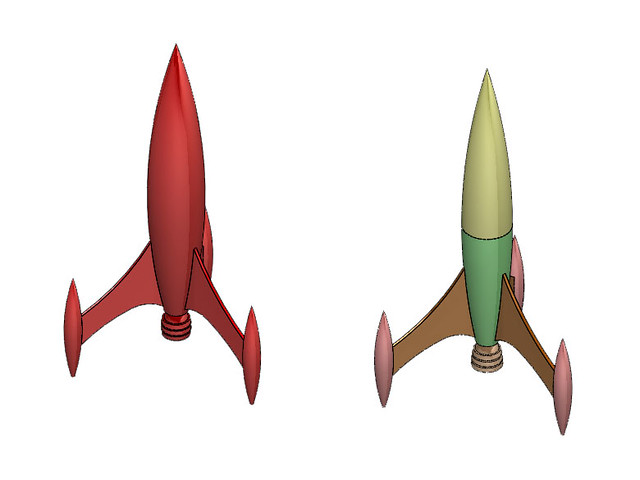

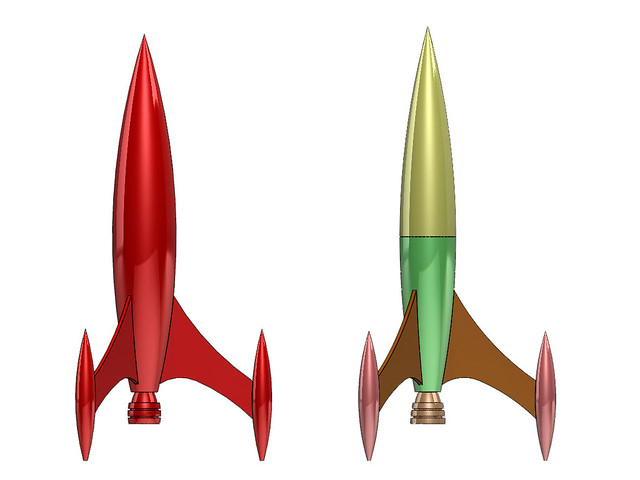

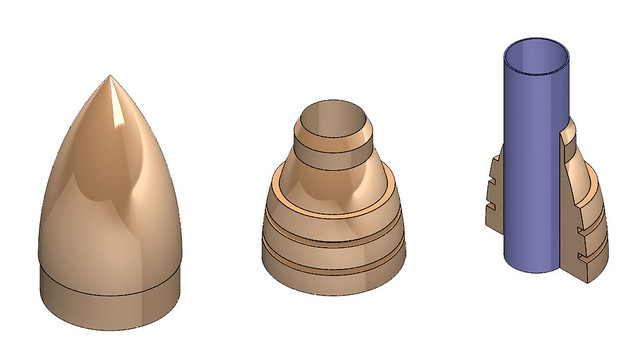

I am thinking of modeling it in SolidWorks so I can come up with an OpenRocket design. So far it looks like a nose cone and a transition for the boat tail, with no tube.

I'm a complete n00b to rocket design. Does this look unstable right out of the box?

I am thinking of modeling it in SolidWorks so I can come up with an OpenRocket design. So far it looks like a nose cone and a transition for the boat tail, with no tube.

I'm a complete n00b to rocket design. Does this look unstable right out of the box?