- Joined

- Dec 7, 2009

- Messages

- 3,553

- Reaction score

- 2,804

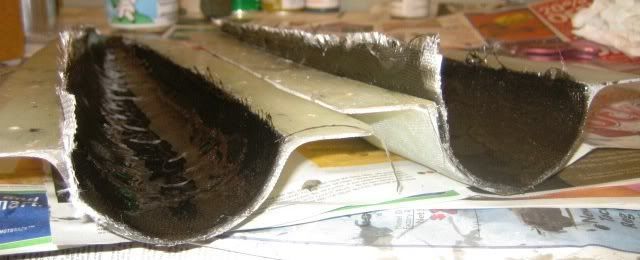

Chris, The reason I use Mahogany is that is what my wood shop buddy has lots of. Anywood will work as long as it's easy to finish. Here is a photo of the finished mold halves.

Tony,Geoff's right 3 failed flights. The first flight was an 2 EX Wimpy Reds M1550 to an L1000. Both motors worked..(my part)..booster recovered no damage, sustainer lake staked total loss. Second flight. AT M1939 to Ellis M1000. I was not there but sustainer total loss. Third flight Cesaroni O5100 to M1000. Sustainer folded right after motor burn out. Booster recovered no damage..sustainer major damage. We still have boosters but no more sustainers. There is talk about giving it another try..but I'm not sure it wil.

Tony

Wimpy Red M1550 to L1000

O-5100 to M1000

I don't understand about it not allowing custom tub diameters. Just type the numbers in when the inch or mm buttons are clicked. Unless it only prints standard diameter tubes, I haven't tried it with custom diameters.

Another guy and I, are almost done 'reading' the entire internet.

Enter your email address to join: