Snuggles, I'm interested. Let's trade some e-mails about those astronauts.

Now, in order to maintain the illusion of making progress I am going to share some pictures of what I have so far.

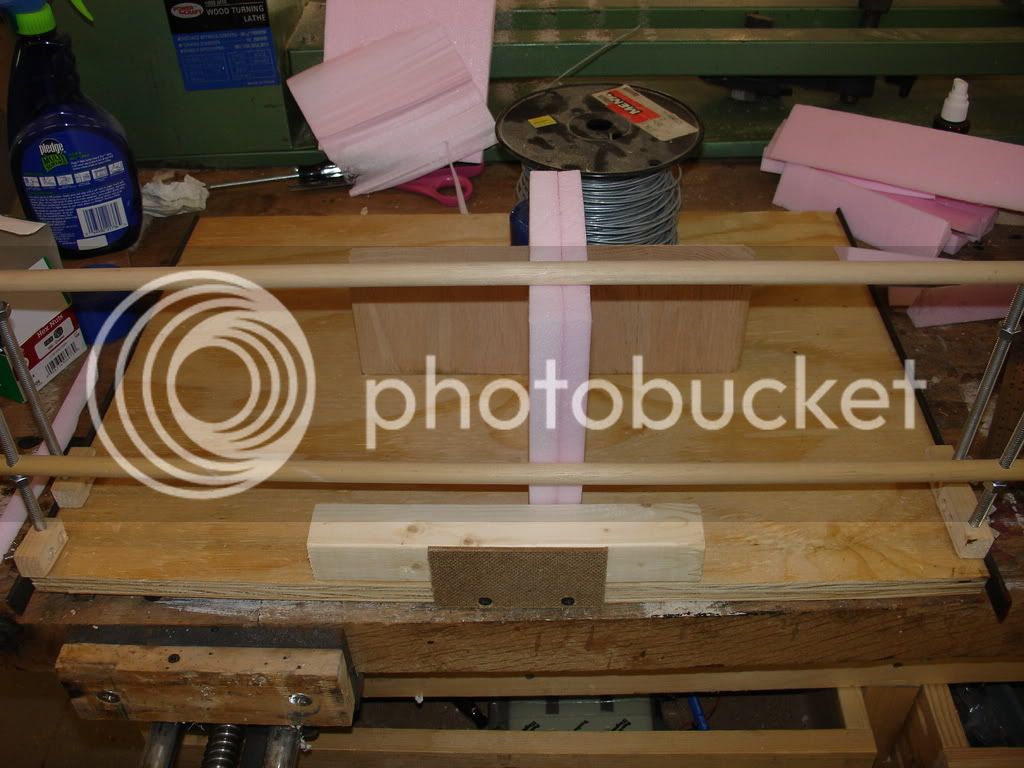

To cut the tapers on the body sections, I made a jig that looks like a set of gymnast's paralell bars to ride the hot wire on to slice corners off the styrofoam blocks. Here's a picture.

This is a picture of the smaller hot wireframe I use. It's missing the two eyebolts and the 28 ga. steel wire in this picture. It's stiff and light.

Here are the templates I made for the body sections from 1/8" hardboard. They were used to line up the dowels on the taper jig above and to define the holes for the BT-80 airframe tubing.

The templates were clamped at both ends of a block and a 3/8" inch hole was drilled through the block lengthwise. The eyebolt, with the hot wire tied to it, was "fished" through the hole and attached to a heavy duty frame. The core then was hot wired. The Core was removed after disconnecting an eyebolt from the frame.

Here's a block with templates clamped.

Here is the drill with the 3/8" installer's bit.

Child with large heavy duty hot wire frame.

Block with core being removed.

Pieces laid out with BT-80 tucked inside for test fit. Snug fit with room for adhesive.

That's it for now. Told you I'm slow.