nukem,

cjl is correct. The full name of the variable, at least as used in the aerospace industry, is

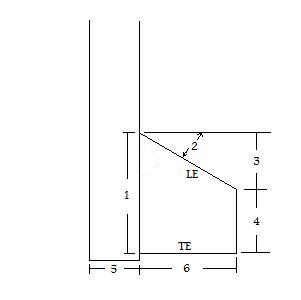

sweepback angle. And yes, it is measured from a line perpendicular to the rocket's longitudinal axis, back to the line of the fin leading edge

Edit: Does this help?

https://www.rocketryforumarchive.com/showthread.php?t=2175

PM me or post qstns here if you need help.

Another thought about fins: when cutting them out from balsa or basswood the grain of the wood should be aligned with the fin leading edge (at least, that's the most simple way to describe it). Grain direction could also be aligned with the 50% chord line of the fin, or anywhere between the 50% chord and the leading edge.

Grain direction should specifically NOT be aligned with the root chord.

For fins cut from plywood, or G10 fiberglass panels, or graphite composite, the structural properties are much more uniform in all directions and the fin template can be laid out on these materials in just about any orientation.

For competition model rockets, or for all-out performance, you really should airfoil the fins (round LE, tapered down to a thin edge from the 50% or 60% chord line down to the TE) and you should taper the thickness from the root to the tip. For sport rockets, it still helps to airfoil the fins (or at least to round the LE) but it is also OK to leave the fins square.

The only time you "want" a sharp (beveled) fin LE is when your rocket is going to spend a

substantial portion of its flight at transonic and supersonic speeds. By substantial, I mean like HALF the flight or more. If your rocket will be subsonic for most of the ascent, then just barely get trans- or supersonic for a few seconds, then immediately go subsonic again when the motor cuts out and the rocket coasts, you will be better off with subsonic fin airfoil shapes. (And probably only 1 in a 100 of the guys who

think their rocket goes supersonic actually achieve that even for a couple seconds; it's a lot more complicated than just believing what a simulation tells you.) Even if your rocket is truly rated to get up to supersonic speeds, the fin edge bevels that you commonly see in photographs are HORRIBLE (high drag). A good fin leading edge bevel needs to reach back to the 20% or 25% chord line, needs to be SHARP on the LE, and needs to be smooth and clean. Same thing goes for bevels on the TE of supersonic rocket fins. For a nice supersonic fin design, study the Nike-Smoke fins (lots of documentation on them out there on the net).

The fin nomenclature used for a certain rocket simulation software uses some terms in common, and they have also come up with some of their own. (Why they did this, instead of using standard industry terms, I don't know, but it's what we have.) The alternate software terms are not better, they are not really worse, they are just different and a little confusing to some people. If you have questions about rocsim fin variables, this is an excellent place to ask qstns and get help, a whole bunch of these TRF guys are experts at turning the crank on rocsim.