patelldp

Well-Known Member

- Joined

- Jan 23, 2009

- Messages

- 5,647

- Reaction score

- 101

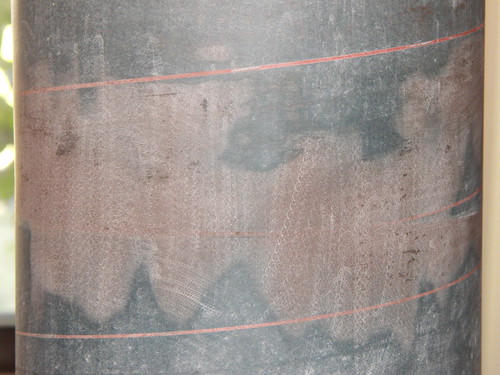

My 4" coupler got jammed in my FWFG cone...here's what I did:

Place the cone on the end of your bench, the lip flush with the edge and the coupler hanging off. Place one hand on the cone, the other on the coupler. Press down on the coupler, with the lip of the cone as your fulcrum. Rotate the cone 90 to 180 degrees, and repeat several, several times. It doesn't feel like much is happening, but if there's any slop then it should budge a little each time.

Try that for 20-30 minutes and see where it gets you.

Place the cone on the end of your bench, the lip flush with the edge and the coupler hanging off. Place one hand on the cone, the other on the coupler. Press down on the coupler, with the lip of the cone as your fulcrum. Rotate the cone 90 to 180 degrees, and repeat several, several times. It doesn't feel like much is happening, but if there's any slop then it should budge a little each time.

Try that for 20-30 minutes and see where it gets you.